What is the role of epoxy-coated corona roller?

In modern industrial production, corona treatment is widely used in the processing of plastic films, paper, textiles and other materials as an important surface treatment technology. Corona roller is the core component for implementing corona treatment, and its quality and performance directly affect the effect of corona treatment. Among the many types of corona rollers, epoxy-coated corona roller has become an important part of corona treatment equipment in many industries with its unique advantages. So, what is the role of epoxy-coated corona roller? Why can it occupy such an important position in the corona treatment process?

This article will analyze the structural characteristics, application advantages and specific role of epoxy-coated corona roller in corona treatment in detail, revealing the value behind this industrial equipment.

What is epoxy-coated corona roller?

Before understanding the role of epoxy-coated corona roller, we need to first understand its basic concept.

Corona roller is a key component used to carry and conduct materials in corona treatment equipment. It helps corona discharge on the surface of the material through synergy with the high-voltage electric field, thereby realizing the activation treatment of the surface of the material. The surface of the traditional corona roller can be coated with different coating materials, among which epoxy coating is a very representative type of coating.

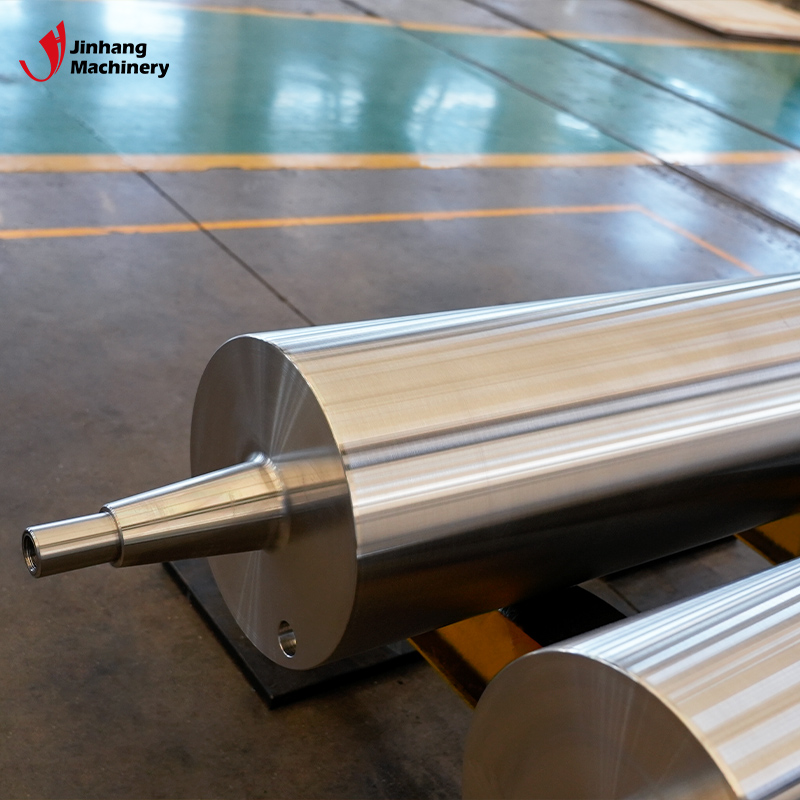

Epoxy coating is a special surface coating made of epoxy resin material, which is evenly coated on the surface of the corona roller after precise processing and curing process. This coating has excellent electrical insulation, mechanical strength and corrosion resistance, which makes the corona roller show more stable performance in high-voltage discharge environment and meet the requirements of complex processing technology.

What is the role of epoxy-coated corona roller?

The role of epoxy-coated corona roller:

1. Provide excellent electrical insulation performance

2. Protect the surface of the material and prevent damage

3. Improve the efficiency and effect of corona treatment

4. Corrosion resistance and extend equipment life

1. Provide excellent electrical insulation performance

The essence of corona treatment is to generate corona discharge on the surface of the material through a high-voltage electric field, thereby changing the physical and chemical properties of the surface of the material. In this process, the corona roller and the material need to be in the corona discharge area at the same time. If the corona roller itself cannot provide sufficient electrical insulation, it will cause corona discharge failure, and even equipment failure or safety accidents.

The main reason why epoxy-coated corona rollers are widely used is their excellent electrical insulation properties. Epoxy resin itself is an excellent insulating material that can effectively isolate the conduction of the electric field, thereby ensuring the stability and safety of corona discharge. In a high-voltage discharge environment, epoxy coating can effectively prevent current leakage and ensure the uniformity and consistency of corona treatment. This feature makes epoxy-coated corona rollers the preferred equipment in high-precision corona treatment processes.

2. Protect the surface of the material and prevent damage

During the corona treatment process, the material needs to be in close contact with the corona roller, and the surface state of the corona roller will directly affect the treatment effect of the material. Traditional metal corona rollers may scratch the surface of the material due to surface roughness, mechanical wear and other reasons, affecting the final quality of the product.

The surface of the epoxy-coated corona roller is precisely processed, and the coating surface is very smooth and uniform, which can effectively reduce the friction between the material and the roller surface and avoid scratches or damage on the material surface. In addition, the epoxy coating also has good wear resistance, and can maintain the integrity and stability of the surface even under long-term continuous use. This feature is particularly important for products such as films and paper that have extremely high requirements for surface quality.

3. Improve the efficiency and effect of corona treatment

The effect of corona treatment is closely related to the uniformity of contact between the material and the corona roller. The epoxy-coated corona roller has extremely high surface accuracy, which can ensure that the material is in close contact with the roller surface during the corona treatment process, thereby achieving uniform distribution of corona discharge. This uniformity is crucial to improving the effect of corona treatment, enabling the material surface to be more evenly and thoroughly activated, thereby improving the adhesion and surface energy of the product.

In addition, the electrical insulation performance of the epoxy-coated corona roller helps to reduce the energy loss during corona discharge, making the electric field more concentrated on the material surface, thereby improving the efficiency of corona treatment. This feature enables the epoxy-coated corona roller to achieve higher production efficiency in large-scale continuous production, helping companies reduce production costs.

4. Corrosion resistance, extending equipment life

During the corona treatment process, the roller surface often needs to withstand high temperatures, humidity and chemical substances. Ordinary metal rollers are prone to corrosion in this environment, affecting the normal use of the equipment and even causing the equipment to be scrapped. Epoxy-coated corona rollers, on the other hand, exhibit strong corrosion resistance and can resist corrosion from a variety of chemicals. Especially when processing materials containing special additives, epoxy coatings can effectively protect the roller body from corrosion damage.

This feature of epoxy coatings significantly extends the service life of corona rollers, reduces the frequency of equipment maintenance and replacement, helps companies save equipment maintenance costs, and improves the overall efficiency of equipment use.

In which industries does epoxy-coated corona roller play a role?

As an important component of corona treatment equipment, epoxy-coated corona rollers are widely used in the following industries:

Plastic film processing industry

Epoxy-coated corona rollers are mainly used for corona treatment of plastic films (such as PE, PP, PET, etc.), improving the printability, coating and adhesion of the film through surface activation.

Paper and packaging industry

In the production of paper and paper packaging materials, corona treatment can effectively improve the adhesion of inks, coatings and material surfaces, ensuring printing quality and subsequent processing performance.

Textile processing industry

Corona treatment of textiles helps to improve the bonding between dyes, coatings and fabric surfaces, and improve the color fastness and durability of products.

Electronic and optical film industry

High-precision electronic materials and optical films have extremely high requirements for surface activation. Epoxy-coated corona rollers can achieve highly uniform corona treatment to ensure the stability of product performance.

What are the advantages of epoxy-coated corona rollers compared with other corona rollers?

Compared with traditional metal corona rollers or ceramic corona rollers, epoxy-coated corona rollers have significant advantages in the following aspects:

● Better electrical insulation performance: effectively prevent current leakage and ensure the stability and uniformity of corona discharge.

● Higher surface smoothness: protect the surface of the material to avoid scratches or wear.

● Stronger corrosion resistance: adapt to harsh working environments and extend the service life of equipment.

● More uniform treatment effect: improve the quality and efficiency of corona treatment to meet high-standard production needs.

High-Quality, Low-Cost Rolls – Customized for Your Industry Needs

JH Machinery offers a wide range of high-quality rolls designed for various industrial applications. Our custom rolls are ideal for industries such as mining, printing, packaging, and automotive testing. We manufacture a variety of roll types, including cooling rolls, heating rolls, and mirror-finished rolls, all produced to meet your exact requirements. Whether you're purchasing in bulk or need a customized solution, we offer low prices, discounts, and competitive wholesale rates. Reach out for a personalized quote today and discover our affordable pricing on industrial rolls.