How to choose the cooling medium for industrial cooling roller?

In many industrial production processes, temperature control plays a vital role, especially in those processes that are sensitive to temperature. In order to ensure production efficiency and product quality, the use of an effective cooling system to properly cool down equipment and workpieces has become an indispensable part of industrial production. As an important cooling equipment, industrial cooling roller has been widely used in many industries, especially in coating, printing, metal processing, plastic processing and other fields. In the working principle of cooling roller, the choice of cooling medium is crucial to the cooling effect.

The cooling medium not only directly affects the cooling efficiency and equipment service life of the cooling roller, but also affects the stability of the production process. Therefore, choosing a suitable cooling medium has a far-reaching impact on ensuring the smooth progress of industrial production. So, how to choose the cooling medium for industrial cooling roller?

In this article, we will discuss in detail the key factors of cooling roller medium selection, and analyze the characteristics and application scenarios of different cooling media to help companies make more scientific and reasonable choices.

What is the working principle of cooling roller?

A cooling roller is a device that uses the principle of heat transfer to cool working materials. During the cooling process, the cooling medium exchanges heat with the roller surface, taking away the excess heat from the roller surface and the material surface, thereby achieving the purpose of cooling. Normally, the surface of the cooling roller is in contact with the material to be cooled (such as plastic, paper, metal, etc.). During this process, the surface of the cooling roller transfers heat from the material to the cooling medium through radiation, convection and conduction, and finally the heat is taken away by the cooling medium.

What are the types of cooling media for industrial cooling rollers?

The selection of cooling media is one of the keys to the working efficiency of cooling rollers. Common types of cooling media include water, air, oil, nitrogen, coolant, etc. Each cooling medium has its own unique properties and applicable scenarios. Therefore, when selecting a cooling medium, it is necessary to consider process requirements, environmental factors, cooling effects, and economic factors.

1. Water as a cooling medium

Water is one of the most common cooling media. Because of its high heat capacity and thermal conductivity, it has been widely used in cooling roller systems. Water has high thermal conductivity efficiency and can quickly take away heat, which is suitable for most industrial scenarios that require large-scale cooling.

Advantages:

● Large heat capacity: Water has a large specific heat capacity and can absorb a large amount of heat in a short time, with high cooling efficiency.

● Low cost: Water is a natural resource with low cost and does not require special storage or treatment facilities.

● Good thermal conductivity: Water has good thermal conductivity and can effectively carry heat away through the cooling roller system.

Disadvantages:

● Corrosion problem: Water easily reacts with metal, causing corrosion and scaling of the cooling roller, so it is necessary to use preservatives or perform regular maintenance.

● Easy to evaporate: Under high temperature or high pressure conditions, water may evaporate, affecting the cooling effect of the cooling roller.

● Applicable scenarios: Water is usually used in cooling systems at low to medium temperatures, especially for large cooling needs, such as cooling in coating, metal processing and paper production.

2. Air as a cooling medium

Air is used as a cooling roller medium, usually in situations where large-scale cooling is not required. Air has a low cooling efficiency, but because it is abundant and does not require special treatment, it is suitable for some applications with less stringent cooling requirements.

Advantages:

● Low cost: Air as a cooling medium requires almost no additional cost and will not corrode equipment.

● No pollution: Air will not pollute equipment and materials, and is suitable for some production environments with high cleanliness requirements.

Disadvantages:

● Low cooling efficiency: Compared with water, air has lower heat capacity and thermal conductivity, and poorer cooling efficiency. A larger cooling roller and longer cooling time are required.

● Affected by environmental conditions: The temperature and humidity of the air will be affected by the external environment, thus affecting the cooling effect.

Applicable scenarios: Air is suitable for low temperature and low power cooling needs, such as cooling processes in electronic components, light industrial products, and certain metal processing.

3. Oil as a cooling medium

Oil is often used in industrial cooling rollers for cooling under stable high temperature conditions. Oil has a higher boiling point and lower volatility, so it performs well in high temperature or high pressure environments. Its heat transfer efficiency is slightly lower than that of water, but in some special applications, the oil cooling effect is very outstanding.

Advantages:

● High boiling point: Oil has a high boiling point and can work for a long time in a high temperature environment without evaporation.

● Good stability: Oil will not scale or corrode as easily as water, and has a long service life.

● Strong antioxidant properties: Oil can maintain good antioxidant properties during long-term use and avoid oxidation reactions.

Disadvantages:

● High cost: Compared with water, oil is more expensive and needs to be replaced and maintained regularly.

● Lower thermal conductivity: Oil has poorer thermal conductivity than water, so it takes longer to achieve cooling effects.

● Applicable scenarios: Oil cooling is suitable for high-temperature processes, such as cooling in metal heat treatment, certain chemical reactions, etc.

4. Coolant as a cooling medium

Coolant is a mixture of water, antifreeze, preservatives and other ingredients, and is usually used for industrial cooling in low-temperature environments. Compared with water alone, coolant has stronger anti-freezing and anti-corrosion properties, so it is widely used in cold environments or metal processing industries.

Advantages:

● Strong corrosion resistance: Coolant can effectively prevent corrosion of cooling roller and extend the service life of equipment.

● Good low-temperature stability: Coolant will not freeze as easily as water, and it works more stably in low-temperature environment.

Disadvantages:

● High cost: Coolant is more expensive than water and needs to be added regularly.

● Complex maintenance: Coolant needs to be replaced and inspected regularly to prevent it from failing.

● Applicable scenarios: Coolant is widely used in occasions that require low temperature and efficient heat dissipation, such as cooling of electronic equipment, automotive cooling systems, and certain precision manufacturing industries.

5. Nitrogen as a cooling medium

Nitrogen is a common inert gas. Due to its low-temperature characteristics, it is often used in cooling occasions that require extremely low temperatures. Nitrogen cooling is very important in some special industries, especially in fields such as high-precision machining and semiconductor manufacturing.

Advantages:

● Good low-temperature cooling effect: Nitrogen has an extremely low temperature and can quickly reduce the temperature of the workpiece.

● Inert gas: Nitrogen has stable chemical properties, does not react with other substances, and does not pollute materials or equipment.

Disadvantages:

● High cost: Nitrogen is expensive to obtain and requires special storage and transportation equipment.

● Limited application range: Nitrogen cooling is mainly used for some specific, high-demand cooling tasks, and has a narrow scope of application.

● Applicable scenarios: Nitrogen cooling is suitable for high-precision, high-demand industries, such as semiconductor manufacturing, aerospace, etc.

Key factors in cooling roller medium selection

When choosing cooling roller cooling medium, the following key factors need to be considered comprehensively:

1. Cooling effect requirements

The demand for cooling roller effect directly determines the choice of cooling medium. If a large amount of heat needs to be removed in a short time, water or coolant is the best choice; if stable operation is required in a high temperature environment, oil or air may be more suitable.

2. Process requirements

Different industrial cooling rollers have different requirements for cooling effects. Some processes may require a low temperature environment, such as metal casting and certain chemical reactions; while some processes may not have strict requirements for cooling rates, such as paper processing or light industrial product processing.

3. Cost and economy

The cost of different cooling media for cooling rollers varies greatly. Water has the lowest cost, while nitrogen and coolant require additional investment. Therefore, it is necessary to weigh the balance between cost and cooling effect when choosing.

4. Environmental factors

Environmental factors, such as temperature, humidity, etc., will affect the selection of cooling roller media. Coolant and oil have better adaptability to cold environments, while water needs to consider antifreeze measures in low temperature environments.

5. Safety and environmental protection

When choosing cooling roller media, companies also need to consider its impact on the environment and safety. Water and air are the most environmentally friendly and safe cooling media, while oil and coolant may involve pollution and maintenance issues.

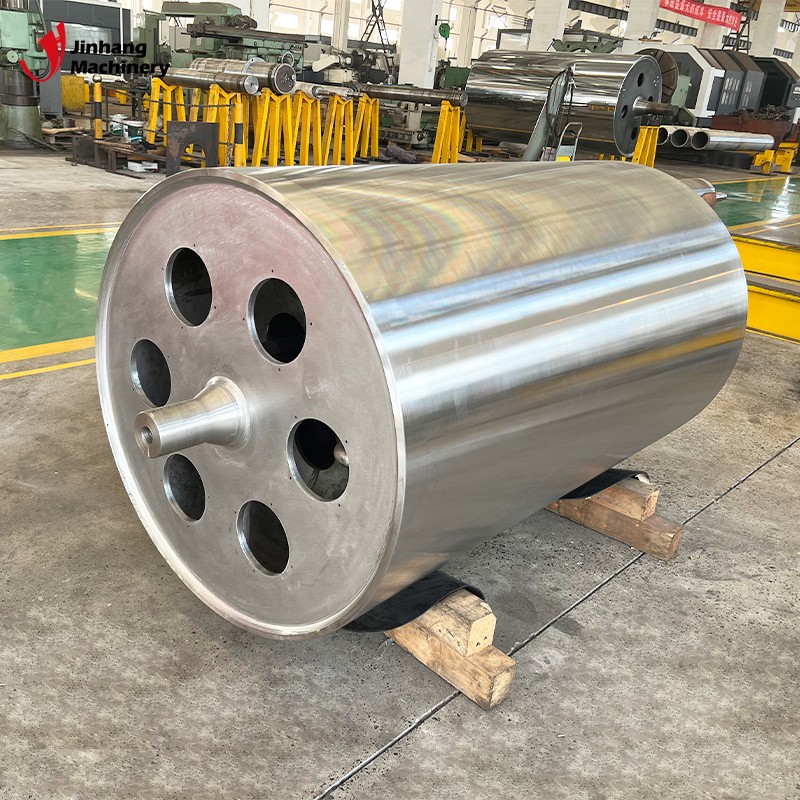

Industrial Rolls Manufacturer with ISO9001 Certification & Custom Solutions

JH Machinery, ISO9001 certified, specializes in the development and manufacturing of custom industrial rolls. Our product portfolio covers cooling rollers, polyurethane rollers, and carbonized coating rollers for various industries like metallurgy, printing, and packaging. We provide competitive pricing, bulk order discounts, and reliable after-sales service including free warranty repairs. Buy directly from our China factory for high-quality, cost-effective rolls designed to improve your production efficiency.