Jinhang Machinery is a high-quality industrial roller manufacturer from China, specializing in the research, development, processing, and customization of various industrial rollers. It can perform in-depth design and precision manufacturing based on customer drawings, operating conditions, and equipment parameters.

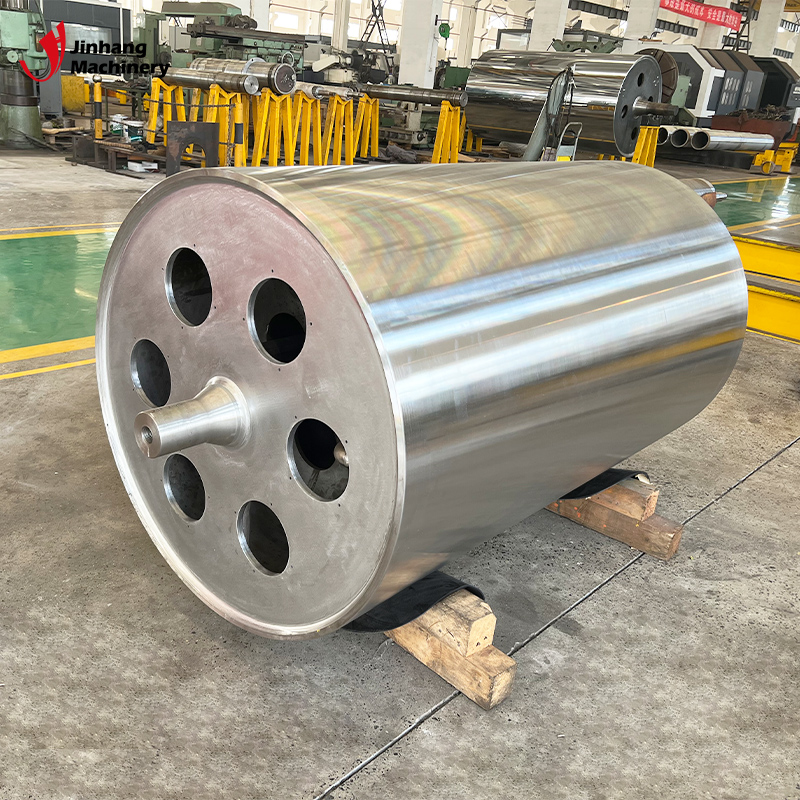

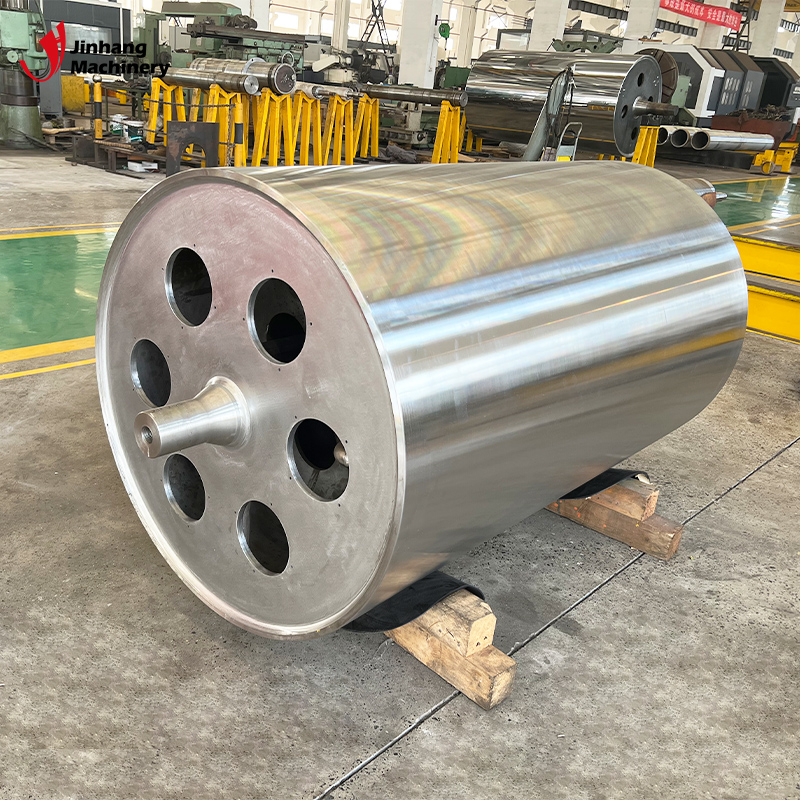

Jinhang Machinery is considered one of the leading Chinese manufacturers of high-performance ceramic corona rollers. If your production line requires a highly stable ceramic corona roller that can operate continuously in extreme environments and has a longer lifespan, then Jinhang is your choice.

Jinhang Machinery manufactures and processes a wide variety of high-precision rollers, including various rubber rollers, polyurethane rollers, heated rollers, mirror rollers, cooled rollers, corona rollers, chrome-plated rollers, tungsten carbide rollers, and other special roller types.