Why is cooling roller an important equipment in the packaging industry?

In the modern packaging industry, various mechanical equipment is used to ensure the speed, quality and consistency of packaging. Among them, cooling roller, as a core equipment, plays an irreplaceable role in the processing and production of various packaging materials. The function of chill roller is not only cooling, but also involves the optimization of product performance and the improvement of production efficiency.

So, why is cooling roller an important equipment in the packaging industry? What specific role does it play? This article will analyze this issue in depth from multiple angles.

What is cooling roller?

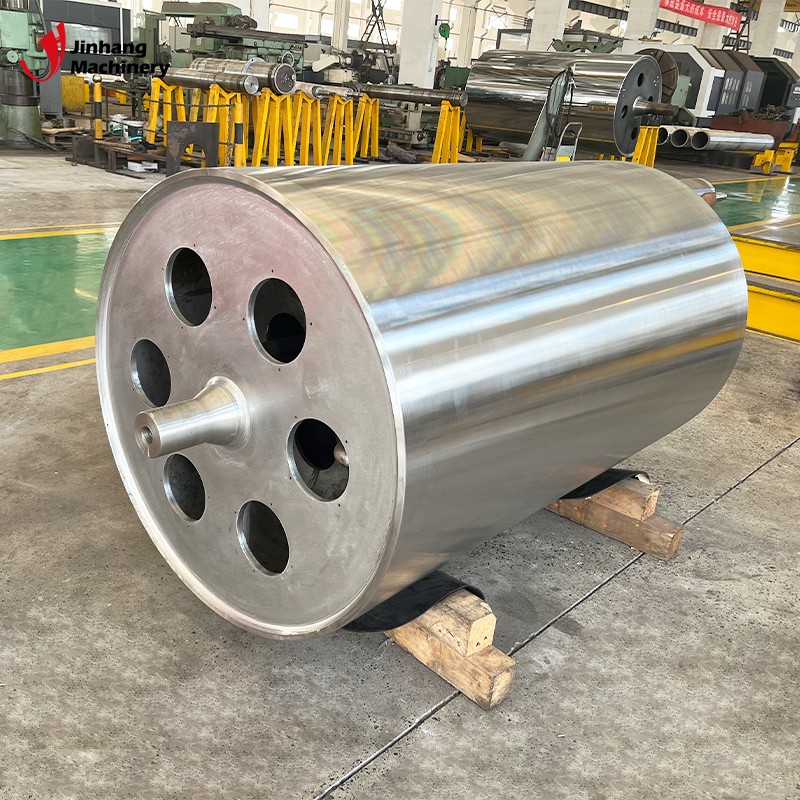

A cooling roller is an industrial roller with a built-in cooling system, which is usually used in packaging material production lines. The temperature of the roller surface is reduced by the internal cooling medium (such as water or oil), thereby cooling the contacting packaging materials. Cooling rollers are usually made of high thermal conductivity metals such as stainless steel or aluminum alloys, and are equipped with a precise temperature control system to ensure the stability and uniformity of the cooling process.

How does cooling roller work?

The working principle of cooling roller mainly includes two key steps:

1. Heat transfer

During the production process of packaging materials, high temperatures are generated due to processes such as extrusion, coating or heating. When the material contacts the surface of the cooling roller, the heat is transferred to the internal cooling medium through the roller surface, and the material temperature decreases accordingly.

2. Cooling medium circulation

The cooling medium (usually cooling water or cooling oil) inside the roller absorbs heat and is discharged, while new cooling medium is introduced into the roller to keep the surface temperature of the roller stable.

This principle ensures that the packaging material is cooled quickly during production to meet the needs of subsequent processing.

What are the applications of cooling roller in the packaging industry?

1. Cooling of thermoplastic packaging materials

In the packaging industry, many packaging materials (such as plastic films, composite materials, etc.) need to undergo high-temperature extrusion or coating processes. In these processes, the material temperature usually reaches hundreds of degrees Celsius. The chill roller helps the material solidify and shape from a liquid or softened state through rapid cooling, thereby obtaining the required mechanical properties and dimensional stability.

2. Temperature control of coating and printing processes

During the coating and printing process, the coating and ink need to be cured quickly within a specific temperature range to ensure adhesion and finish. Cooling roller can evenly reduce the surface temperature of packaging materials, avoiding cracking, shedding and other quality problems of coating or ink.

3. Lamination process of composite materials

Composite materials are usually composed of multiple layers of materials with different properties. During the lamination process, heat will cause expansion or thermal deformation of each layer of material. Cooling roller fixes the position of each layer of material by rapid cooling, ensuring the structural integrity and stable performance of the composite material.

4. Stable output of thermoforming process

Thermoforming packaging (such as plastic pallets, food packaging boxes, etc.) needs to be formed before the material cools down. Cooling roller helps the material to be fixed by controlling the temperature during this process, and prevents dimensional deviation caused by thermal expansion and contraction.

Why is chill roller an important equipment in the packaging industry?

1. Ensure product quality

Cooling roller helps packaging materials maintain their mechanical properties and appearance characteristics by rapid and uniform cooling. For example, plastic film can avoid warping or shrinkage caused by thermal stress under the action of cooling roller, thereby ensuring the thickness uniformity and flatness of the film.

Question 1: What will happen without cooling roller?

Without cooling rollers, packaging materials may experience excessive deformation, unstable dimensions, surface quality defects, and other problems during the cooling process, which directly affect the quality of the finished product.

2. Improve production efficiency

The chill roller can quickly reduce the material temperature, allowing the packaging production line to run at a faster speed. By reducing the time required for the material to solidify, the chill roller significantly shortens the production cycle and increases production capacity.

Question 2: Why is the cooling speed important?

The cooling speed directly determines the operating speed of the production line. If the cooling efficiency is low, the material may take longer to solidify, resulting in bottlenecks in the production line and affecting overall efficiency.

3. Improve the stability and durability of the equipment

In high-temperature processes, if there are no effective cooling measures, the surface of the packaging production equipment may be damaged by high temperature, resulting in a shortened service life. By controlling the process temperature, the chill roller not only protects the packaging material, but also extends the service life of the production equipment.

Question 3: What impact will excessive temperature have on the equipment?

The long-term operation of the equipment under high temperature conditions may cause thermal expansion, increased wear and material fatigue of the components, and ultimately cause equipment failure or shutdown.

4. Meet diverse needs

The packaging industry involves a variety of materials and processes, and the requirements for cooling systems vary. Cooling rollers can adapt to the process requirements of different materials through flexible design and precise temperature control functions. For example, for plastic films, chill rollers need to ensure that the surface remains smooth during cooling; while for composite materials, the temperature gradient needs to be controlled to avoid stratification.

What are the key performance indicators of chill rollers?

1. Thermal conductivity

The thermal conductivity of chill rollers directly affects their cooling efficiency. High thermal conductivity metal materials (such as aluminum alloys or copper) are often used to manufacture rollers to ensure rapid heat transfer.

2. Temperature control accuracy

Cooling rollers require precise temperature control, especially in packaging production that requires high consistency. Precise temperature control systems can avoid the impact of temperature fluctuations on material properties.

3. Surface treatment process

The surface treatment process of cooling rollers (such as chrome plating or polishing) determines its contact effect with packaging materials. High-quality surface treatment can improve cooling efficiency and reduce the risk of material adhesion or scratches.

4. Internal cooling system design

The cooling medium flow path design inside the chill roller has an important influence on the cooling efficiency. The optimized flow path design can ensure that the cooling medium is evenly distributed inside the roller and improve the overall cooling effect.

China-Based Supplier of Customized Industrial Rolls with Fast Turnaround

JH Machinery supplies customized industrial rolls with a fast turnaround time to help meet your urgent production schedules. Our rolls include electroplated, mirror-finished, and polyurethane types suitable for multiple sectors such as packaging and metallurgy. We provide competitive factory-direct prices, bulk discounts, and tailored solutions. Get in touch now!