Which Industrial Cooling Roller Cools Down the Fastest?

In continuous industrial production lines, cooling rollers, along with heating rollers, form the core temperature control system of the processing zone. If heating rollers determine the thermal processing properties of materials, then cooling rollers determine the quality of material forming, curing, stabilization, and surface structure. Different types of chill rollers vary in their internal structure, cooling medium, flow channel design, and surface treatment methods, resulting in significant differences in cooling capacity.

Therefore, when selecting production equipment, companies often ask a key question: Which industrial cooling roller cools down the fastest?

This article will focus on this core question, analyzing the differences in cooling efficiency among different cooling rollers from the perspectives of heat transfer, structural design, and cooling medium, and systematically explaining the factors determining the cooling capacity of chill rollers.

What factors affect the cooling rate of a cooling roller?

To discuss which cooling roller cools down the fastest, we must first understand several key factors affecting the cooling rate.

These factors include:

• Internal flow channel structure of the cooling roller

• Type and flow rate of the cooling medium

• Thermal conductivity of the roller material

• Roller surface treatment

• Roller thickness

• Roller diameter

• Production line operating speed

• Contact area and contact time between the material and the cooling roller

Among these, the internal structure of the cooling roller and the cooling medium are the two most crucial factors determining the cooling rate.

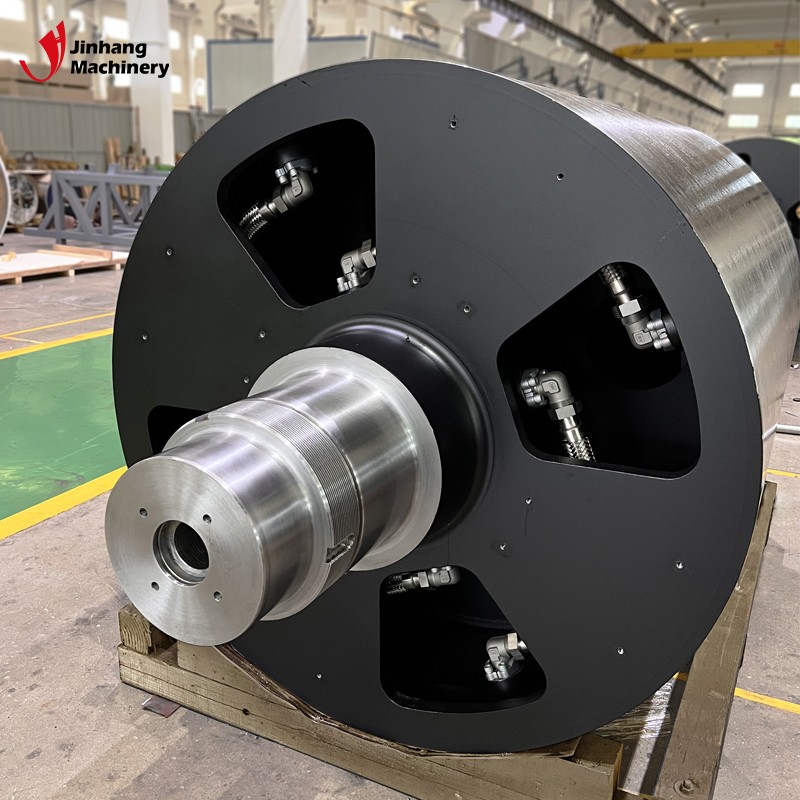

Does the internal structure of the cooling roller directly affect the cooling rate?

Absolutely, and the impact is very significant.

Common internal structures of cooling rollers include:

1. Straight-through flow channel cooling roller

2. Spiral flow channel cooling roller

3. Two-way spiral cooling roller

4. Partitioned or zoned circulation cooling roller

5. Multi-loop constant-temperature cooling roller

These internal structures have a significant impact on the cooling rate because different flow channel structures determine:

• Uniformity of cooling medium flow

• Size of heat exchange area

• Whether the coolant can cover the entire roller body

• Consistency of temperature difference distribution

• Maximization of coolant heat exchange efficiency

In comparing cooling rates, the following conclusion is most crucial: The more uniform the flow channel, the more sufficient the coolant coverage, and the larger the heat exchange area, the faster the cooling roller cools down.

Generally speaking, two-way spiral structures and high-coverage flow channel designs have higher cooling efficiency than traditional straight-through flow channels.

Does the material of the cooling roller affect the cooling rate?

Yes, the thermal conductivity of the roller material directly affects the cooling rate.

Common cooling roller materials include:

• High-quality carbon steel

• Alloy steel

• Stainless steel

• Special coated steel

• Aluminum alloy (rare, used in special light-load processes)

The thermal conductivity of different materials varies significantly, with:

• Aluminum alloy has the fastest thermal conductivity but low load-bearing capacity

• Carbon steel and alloy steel offer the best overall performance

• Stainless steel has slightly slower thermal conductivity but strong corrosion resistance

Therefore, in actual production lines: Cooling rollers with high thermal conductivity metals combined with a high-efficiency internal flow channel structure typically have faster cooling capabilities.

Does the type of cooling medium determine the cooling speed of the chill roller?

The cooling medium is one of the most critical factors affecting the cooling speed of the chill roller.

Common cooling media include:

1. Cooling water (most commonly used)

2. Chilled water (low-temperature water)

3. Ethylene glycol solution

4. Oil cooling (less commonly used for cooling, more often for temperature control)

5. Mixed cryogenic coolant

The characteristics of different cooling media are as follows:

• Ordinary cooling water: Wide applicability, but limited lower temperature limit

• Chilled water: Lower temperature, removes heat faster

• Ethylene glycol: Resistant to low temperatures but slightly weaker cooling capacity than water

• Oil cooling: Low heat capacity and slow cooling

• Cryogenic fluids: Can provide extremely low temperatures, strong heat exchange capacity

Therefore, we can draw a clear conclusion:

If cooling speed is the primary objective, cooling rollers using chilled water or cryogenic coolant will cool the fastest.

Does the surface treatment of the cooling roller affect cooling efficiency?

Yes, it does, but the impact is mainly reflected in the material contact effect.

Common surface treatments for cooling rollers include:

• Mirror finish

• Sandblasting

• Hard chrome plating

• Oxidation

• Ultra-precision polishing

Different treatments affect:

1. The contact area between the material and the cooling roller

2. The thermal conductivity resistance of the material

3. Surface micro-unevenness

Generally speaking:

Mirror-finish cooling rollers have a larger contact area and higher heat transfer efficiency, resulting in faster cooling.

Do the thickness and diameter of the cooling roller affect the cooling rate?

A thicker roller has a higher heat capacity, leading to slower cooling.

A larger roller diameter results in a larger contact area and longer contact time, potentially leading to more uniform cooling but not necessarily faster cooling.

Therefore:

• Thin-walled rollers cool faster in some cases.

• Larger diameter cooling rollers are more suitable for materials requiring stable cooling.

However, in industrial settings, structural strength is a strict requirement, so cooling speed cannot be achieved simply by "thinning the roller wall."

Which type of cooling roller has the fastest cooling rate?

Based on the preceding analysis, we can conclude that the fastest cooling speed is not determined by a single, fixed model, but rather by the following combination:

The fastest cooling speed generally refers to: Chill rollers with a bidirectional spiral flow channel + thin-walled structure + high thermal conductivity material + mirror finish + low-temperature chilled water medium.

The functions of each element are as follows:

• Bidirectional spiral flow channel → High coolant coverage and large heat exchange area

• High thermal conductivity material → Fast heat transfer speed of the roller body

• Thin-walled structure → Low heat capacity, faster cooling

• Mirror surface → Low contact thermal resistance, rapid material cooling

• Chilled water medium → Low initial temperature, rapid heat removal

Furthermore, a sufficiently high coolant flow rate will further enhance the cooling speed.

Therefore, to answer the question:

Which industrial cooling roller has the fastest cooling speed?

We can definitively say:

A high thermal conductivity metal cooling roller employing a bidirectional spiral high-efficiency flow channel combined with chilled water circulation is the fastest cooling roller structure.

These types of cooling rollers typically offer the highest heat exchange efficiency, the most uniform temperature distribution, and the fastest heat removal capacity.

Are fast-chill rollers suitable for all processes?

Not necessarily.

While rapid cooling offers significant advantages, not all production lines require "faster is better" chill rollers. For example:

• Some materials require slow cooling to achieve a better internal structure.

• Some processes require maintaining a constant temperature zone rather than rapid cooling.

• Some materials develop surface stress under rapid cooling.

Therefore, process objectives determine the type of chill roller, not simply the fastest cooling speed.

However, if we only discuss "which chill roller cools the fastest," the answer is quite clear: it's the combination of chill rollers mentioned above.

Is the cooling efficiency of a cooling roller related to temperature uniformity?

Highly related.

Cooling speed is one aspect; uniformity of cooling is another. If a cooling roller cools quickly but the temperature difference is large, it can lead to:

• Uneven material thickness

• Unstable surface tension

• Decreased mechanical properties

• Poor product consistency

Therefore: The cooling roller that cools fastest is usually the one with the smallest temperature difference, because efficient flow channels allow for a more uniform distribution of heat exchange.

This is why efficient flow channel design is so important.

Does a lower cooling temperature on a cooling roller result in faster cooling?

In most cases, yes, but it's not unlimited.

Low-temperature coolants can significantly improve heat exchange efficiency, but:

• If the temperature is too low, condensation or frost will occur.

• Excessive temperature differences can cause thermal shock to the material.

• The equipment may require additional insulation.

• Excessive cooling can affect material processability.

Therefore, the cooling temperature usually needs to consider the process window, rather than simply "the lower the better."

However, from a pure cooling speed perspective, low-temperature coolants are indeed the fastest cooling method.

Which industrial chill roller cools the fastest?

A comprehensive analysis of factors such as the structure, material, cooling medium, and surface treatment of chill rollers leads to the following clear conclusions:

Chill rollers with the fastest cooling speeds generally possess the following characteristics:

• Bidirectional spiral flow channel structure

• High thermal conductivity metal material

• Thin-wall design (within structural limits)

• Mirror-finish surface finish

• Low-temperature chilled water as the cooling medium

• High-flow-rate coolant circulation

These conditions, combined, maximize cooling efficiency, enabling the chill roller to achieve the fastest heat transfer and cooling speeds.

In other words:

High thermal conductivity chill rollers employing a high-efficiency flow channel design and operating with low-temperature coolant circulation are currently the fastest type of chill roller used in industrial applications.

Why choose Jinhang Machinery as your roller manufacturer?

As a professional roller manufacturer, Jinhang Machinery has been committed to precision roll engineering since 2001. Our factory, covering 13,000 square meters, operates advanced CNC lathes, Italian grinding systems, PU casting equipment, and automated welding lines.

We design and produce rollers in multiple configurations, including heating, rubber, chrome-plated, and carbide-coated rolls. Custom drawings are also welcome.