- Home

- >

- Products

- >

- Chill Roller

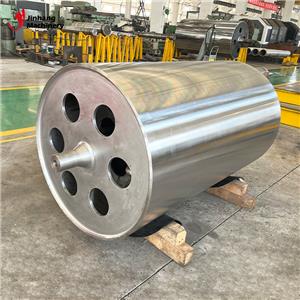

Chill Roller

1.Structure: various structure designs such as spiral flow channel and jacket type.See the structure of the heating rollers.The surface of the roller can be customized according to the needs.

2.Processing size and precision:

the maximum outer diameter:2000mm

the maximum length:8000mm

the maximum processing precision :0.002mm

3.Application:Food, pharmaceutical packaging industry, optical film, solar cell industry; Lithium film and coating equipment.

Product description:

The purpose of the chill roll is to reduce the deformation and shrinkage of the material before the material is rolled, and improve the product qualification rate and production efficiency, in order to reduce the deformation of the material due to excessive temperature or shrinkage during cooling during the rolling of the film coil.

In practical application, the chill roll is generally installed behind the drum drying device, which is used to reduce the temperature of ultra-thin coiled materials to the ideal coiling temperature to avoid the occurrence of defective products. The excellent heat dissipation of cooling roller is widely used in food, drug packaging industry, optical film, solar cell industry; Lithium film and coating equipment.