Which is better, chrome plated roller or stainless steel roller?

In coating, printing, packaging, paper processing and other industries, the choice of roller directly affects the quality and production efficiency of the product. Chrome plated roller and stainless steel roller are two common industrial roller materials, each with different advantages and applicable fields.

So, which is better, chrome plated roller or stainless steel roller? This article will make a detailed comparison of the characteristics, usage scenarios, cost, maintenance and performance of these two materials to help companies make the most suitable choice according to production needs.

Concept of chrome plated roller and stainless steel roller

What is chrome plated roller?

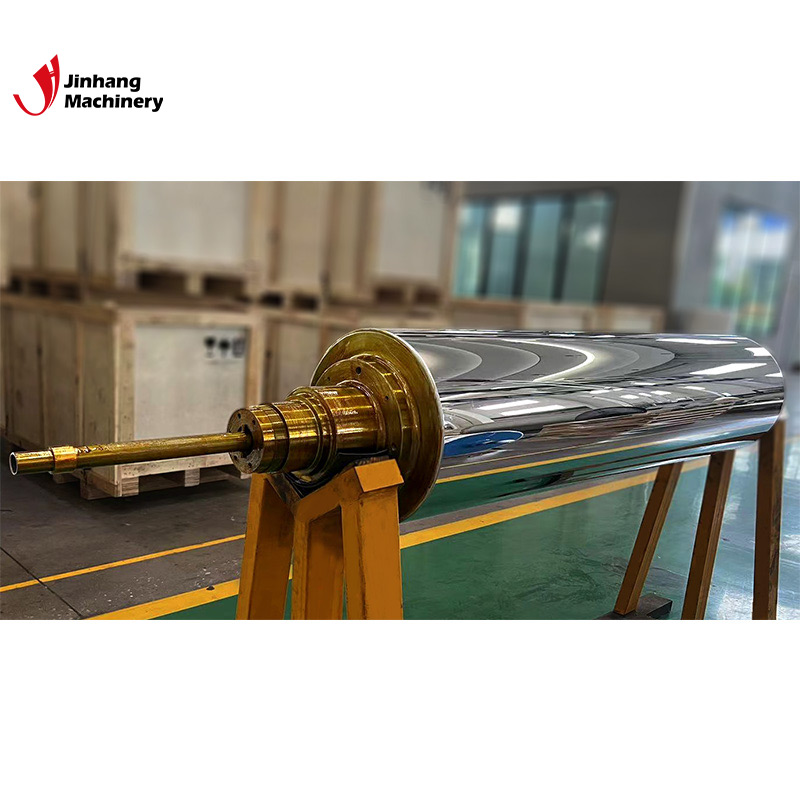

Chrome plated roller refers to a roller with a layer of chromium (Cr) on the surface of the metal roller through electroplating or chemical plating technology. The chromium layer can not only enhance the hardness, wear resistance and corrosion resistance of the roller, but also has good surface smoothness, which is suitable for high-precision coating, embossing and printing processes.

What is stainless steel roller?

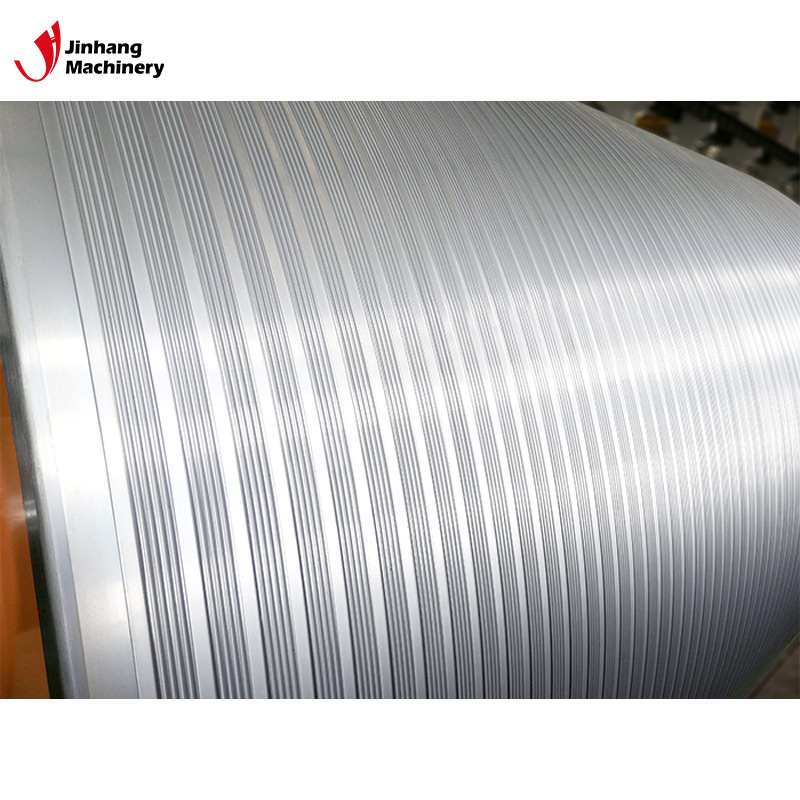

Stainless steel roller is a roller made of stainless steel material. Stainless steel is widely used in a variety of industrial environments due to its excellent corrosion resistance, high temperature resistance and strength. Compared with chrome plated rollers, stainless steel rollers have stronger wear resistance and oxidation resistance, but their surface finish and corrosion resistance may be slightly inferior to chrome plated rollers.

Chrome plated rollers vs. stainless steel rollers: Performance comparison

1. Wear resistance

Wear resistance is an important indicator for measuring roller performance, especially in high-frequency and high-load industrial applications, where wear resistance directly affects the roller's service life and production efficiency.

· Chrome plated rollers: The chrome layer has a high hardness, usually reaching HRC 60-70, which can effectively improve the roller's wear resistance. Chrome plated rollers are often used in processes that require high wear resistance, such as coating, printing, and embossing.

· Stainless steel rollers: Stainless steel materials have a lower hardness, but still have a certain wear resistance. Compared with chrome plated rollers, stainless steel rollers have relatively weaker wear resistance, but they can still provide sufficient performance in some occasions that do not require particularly high wear resistance.

2. Corrosion resistance

Rollers are often exposed to harsh conditions such as moisture, chemical corrosion or high temperature in industrial environments, so corrosion resistance is particularly important.

· Chrome plated roller: The chrome layer can effectively resist the erosion of chemicals such as acids, alkalis and salts, providing strong corrosion resistance, especially when dealing with solvents or acidic substances, chrome plated rollers perform well.

· Stainless steel rollers: Stainless steel has natural corrosion resistance and can resist oxidation and the erosion of most acidic and alkaline substances, so it performs better in humid or highly corrosive environments. However, in some highly corrosive environments (such as concentrated acid and high temperature environments), the corrosion resistance of stainless steel rollers may not be as good as chrome plated rollers.

3. Surface finish

Surface finish is crucial for processes such as coating and printing. A smooth surface ensures uniform coating of liquids and improves the quality of the product.

· Chrome plated roller: Due to the smoothness and hardness of the chrome layer, the surface of chrome plated rollers is usually very smooth. The chrome layer not only improves the flatness of the roller surface, but also reduces the adhesion of the liquid, making the coating effect more uniform, which is suitable for high-precision coating and printing processes.

· Stainless steel roller: Although the surface of stainless steel also has a certain degree of smoothness, it is usually not as smooth as the chrome plated roller. Without additional polishing or surface treatment, the surface of the stainless steel roller may be rough, which will affect the coating effect.

4. Strength and hardness

The strength and hardness of the roller are directly related to its performance under high load and high-speed operation.

· Chrome plated roller: Through the chrome plating process, a chrome layer with higher hardness is formed on the surface of the metal roller, which improves the compressive strength and wear resistance of the roller, and can remain stable under high load and high-speed operation.

· Stainless steel roller: Stainless steel itself has higher tensile strength and toughness, but compared with chrome plated roller, the hardness of stainless steel roller may be slightly inferior. Therefore, stainless steel rollers may suffer certain wear and tear when operating for a long time or facing high-intensity pressure.

Chrome plated roller vs. stainless steel roller: Applicable scenarios

Depending on the performance differences, chrome plated rollers and stainless steel rollers have their own advantages in different industrial applications.

1. Applicable scenarios of chrome plated rollers

·Coating process: Chrome plated rollers are widely used in the coating industry, especially in film, paper and other precision coating processes. Due to its smooth surface, it can achieve uniform coating and high coating accuracy, and is particularly suitable for processing low-viscosity liquids.

·Printing industry: During the printing process, the smoothness and corrosion resistance of chrome plated rollers ensure the precise transfer of ink and the stability of printing effects, and are widely used in the production of high-quality printed products.

·Metal processing and embossing: In some metal processing and embossing processes, the hardness and wear resistance of chrome plated rollers can effectively improve production efficiency and extend the service life of equipment.

2. Applicable scenarios of stainless steel rollers

·Food processing and pharmaceutical industries: Due to the good corrosion resistance and strength of stainless steel rollers, they are widely used in food processing and pharmaceutical industries, which can ensure safety and stability in long-term operation.

·High temperature environment: Stainless steel has good high temperature resistance and is suitable for scenes working in high temperature environment, such as high temperature coating, hot pressing, etc.

·Occasions with high cleanliness requirements: Stainless steel rollers are widely used in production processes that require high hygiene standards due to their natural corrosion resistance and oxidation resistance. They can effectively prevent bacterial growth and meet strict cleaning requirements.

Chrome plated roller vs. stainless steel roller: cost comparison

When considering chrome plated rollers and stainless steel rollers, cost is a very important factor. The manufacturing process and material costs of the two are different, which may affect the overall investment and economic efficiency of use.

·Chrome plated roller: Since chrome plating requires processes such as electroplating or chemical plating, this will increase additional processing costs. In addition, the thickness and uniformity of the chrome plating layer will also affect the price. In some cases, the initial investment of chrome plated rollers may be higher.

·Stainless steel rollers: The raw material cost of stainless steel rollers is higher, but due to their natural corrosion resistance, additional surface treatment is usually not required, reducing processing costs. In addition, stainless steel rollers have a longer service life, so they may be more cost-effective in some applications.

Customized Industrial Rolls Factory with Advanced Equipment and Low Prices

JH Machinery is equipped with advanced machines like CNC lathes, dynamic balancing machines, and imported grinding equipment to produce customized industrial rolls of exceptional quality. We manufacture rolls for various industries including metallurgy, mining, and printing. Our factory offers low-price wholesale options, volume discounts, and flexible purchasing terms. Buying direct from us guarantees competitive pricing and timely delivery. Reach out today!