What kind of roller is better than tungsten carbide roller?

In industrial production, roller is a key mechanical component, widely used in papermaking, printing, steel, plastic processing and other fields. Tungsten carbide roller is often considered to be one of the excellent industrial roller materials due to its high hardness, wear resistance and corrosion resistance.

For specific processes or application scenarios, is there a material with better performance than tungsten carbide roller? This question deserves further discussion.

Advantages and disadvantages of tungsten carbide roller

1. What are the advantages of tungsten carbide roller?

Tungsten carbide is a compound composed of carbon and tungsten. Its hardness is close to that of diamond, and it has excellent corrosion resistance and high temperature stability. These characteristics make it very suitable for high wear, high pressure and high temperature conditions. For example, in the field of metal rolling, tungsten carbide roller can withstand severe friction for a long time, and in the chemical processing industry, its corrosion resistance can withstand acid and alkali environments.

2. What are the disadvantages of tungsten carbide roller?

Although tungsten carbide rollers have excellent performance, they are not the best choice in all scenarios.

● Brittleness problem: Although tungsten carbide has high hardness, it has low toughness and is prone to cracks or breaks under extreme stress.

● Processing difficulty: The manufacturing and repair costs of tungsten carbide rollers are high, and its hardness places higher requirements on cutting and grinding processes.

● Heavy weight: The high density of tungsten carbide makes it heavier than rollers made of other materials, which is not suitable for some lightweight or high-speed equipment.

Therefore, in some specific processes, rollers of other materials may need to be selected to better meet production needs.

What material roller is better than tungsten carbide roller?

In industrial applications, the selection of roller material usually requires a comprehensive consideration of factors such as hardness, toughness, corrosion resistance, weight and cost. The following materials may be better than tungsten carbide rollers under certain conditions.

1. Ceramic Roller

Ceramic material is a high-performance material favored in modern industry. It is widely used in high-precision and high-temperature environments because of its extremely high hardness, corrosion resistance and high-temperature resistance.

● Advantages: Ceramic rollers are lighter than tungsten carbide rollers and more suitable for high-speed operation. Its excellent antioxidant ability makes it perform well in high-temperature environments, and it has strong resistance to acid and alkali chemicals.

● Applicable scenarios: used for high-precision printing, optical film production and high-temperature metallurgical processes.

● Limitations: Ceramic materials are more brittle and easily break under heavy load impact.

2. Polyurethane Roller

Polyurethane is a polymer material with high elasticity, wear resistance and chemical resistance, and is often used as a covering layer for industrial rollers.

● Advantages: Polyurethane rollers have good flexibility, can absorb impact and reduce noise, and have good tolerance to most industrial chemicals. Compared with tungsten carbide, it is light in weight, low in cost, and not easy to cause damage to equipment.

● Applicable scenarios: Suitable for low wear and high elasticity requirements in food processing and papermaking industries.

● Limitations: The hardness of polyurethane rollers is much lower than that of tungsten carbide, and is not suitable for high wear or high temperature environments.

3. Nickel-Based Alloy Roller

Nickel-based alloys are known for their excellent high-temperature oxidation resistance and corrosion resistance, and are particularly suitable for applications in harsh chemical environments.

● Advantages: Nickel-based alloy rollers have better toughness than tungsten carbide rollers, and are more stable in extremely high temperature and chemical corrosion environments.

● Applicable scenarios: Petrochemical industry, chemical processing, and high-temperature kiln processes.

● Limitations: The hardness is slightly lower than that of tungsten carbide, and may not be suitable for extremely high wear conditions.

4. High-Performance Steel Roller

High-performance steel can achieve a good balance between hardness and toughness through alloying and heat treatment technology.

● Advantages: Compared with tungsten carbide rollers, high-performance steel rollers have higher impact toughness and fatigue resistance, lower manufacturing costs, and simpler processing and maintenance.

● Applicable scenarios: Widely used in heavy-duty applications in steel rolling, papermaking, and textile industries.

● Limitations: Corrosion resistance and hardness are slightly lower than tungsten carbide.

What are the key factors in selecting industrial roller materials?

1. Hardness and toughness

Tungsten carbide rollers have extremely high hardness, but ceramic rollers or nickel-based alloy rollers may be a better choice when toughness or impact resistance is required.

2. Corrosion resistance

If the application involves strong acid and alkali environments, ceramic rollers and nickel-based alloy rollers can provide higher corrosion resistance.

3. Economic and maintenance costs

The high manufacturing and repair costs of tungsten carbide rollers limit their widespread use in certain scenarios. Polyurethane rollers and high-performance steel rollers are more cost-effective.

4. Operating temperature and speed

For high-temperature and high-speed processes, ceramic rollers may perform better than tungsten carbide rollers. In applications where low temperatures or high flexibility requirements are required, polyurethane rollers are ideal.

Custom Roll Solutions for Automotive Testing and Packaging Industries

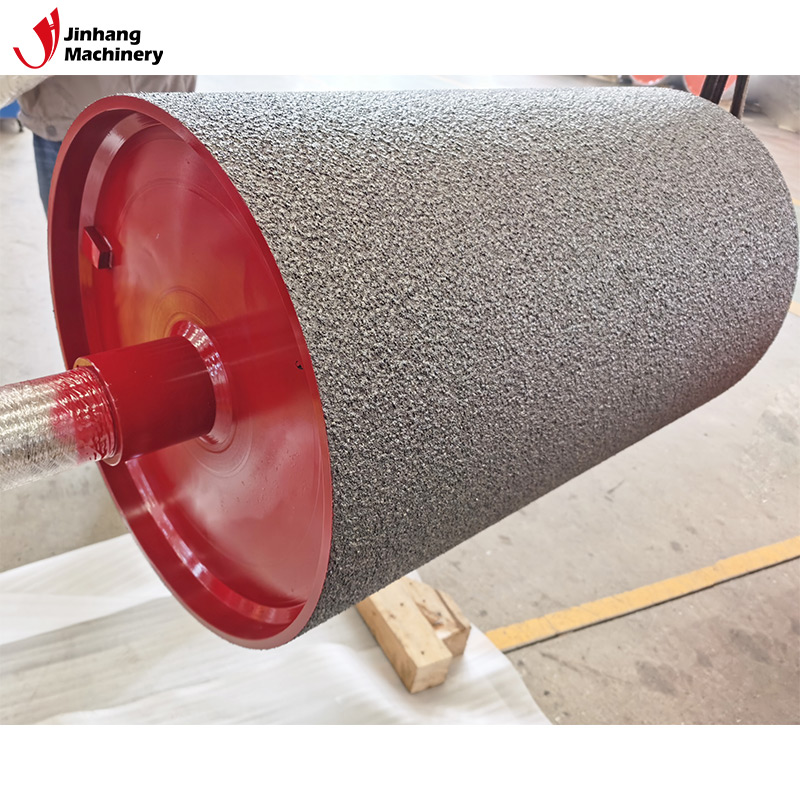

JH Machinery specializes in custom industrial rolls for automotive testing and packaging industries. Our product portfolio includes tungsten carbide-coated, mirror-finished, and polyurethane rolls made to fit your precise needs. We deliver high-quality products from our China factory at competitive prices with discounts on bulk orders. Our flexible customization options and reliable after-sales support make us a trusted supplier.