Which printing methods use anilox rollers to transfer ink to the printing plate?

In the printing industry, various technologies and equipment are used to ensure high-quality printing results, and anilox rollers, as key components, play a vital role. The unique design and function of anilox rollers make them an indispensable part of many printing processes, especially in the process of accurately transferring ink to the printing plate.

This article will take a detailed look at the printing methods that use anilox rollers, explore their working principles, application scenarios, and why anilox rollers play such an important role in these printing methods.

What is anilox roller?

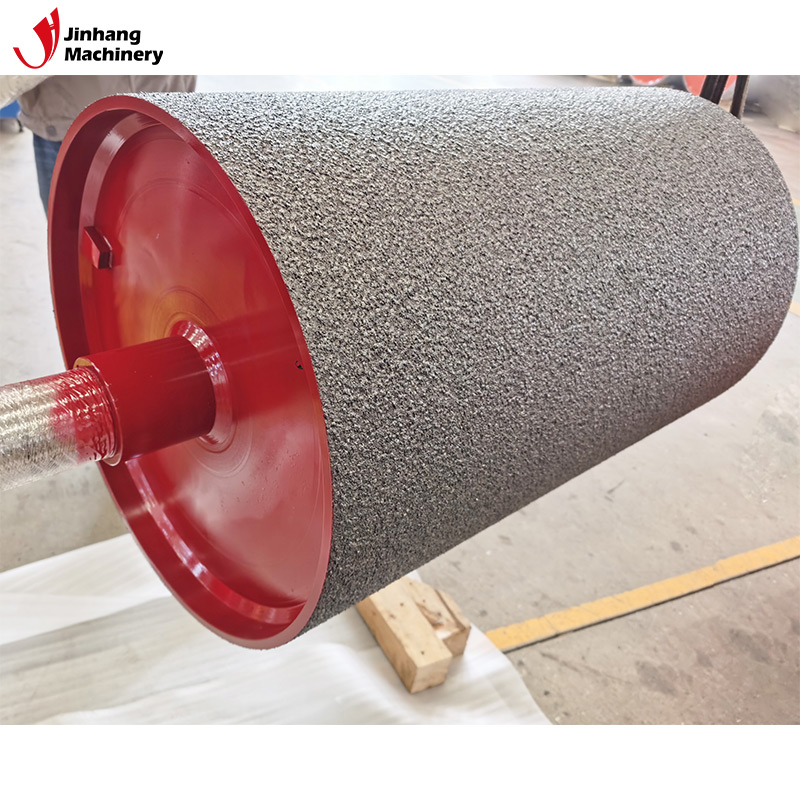

Anilox rollers are rollers with tiny mesh holes (called cells) on their surface, which are specially designed to accurately control the amount of ink or coating transferred. The surface of anilox rollers is coated with a layer of ceramic or metal and laser engraved to form countless fine small mesh holes. These mesh holes are designed to evenly hold and transfer a certain amount of ink or other liquids.

The basic working principle of anilox rollers is that when its surface contacts ink, the ink is stored in the mesh holes and then evenly transferred to the surface of the printing plate or substrate by rotation. Anilox rollers are widely used in various printing processes, especially those that require high-precision ink transfer.

What are the printing methods using anilox rollers?

1. Flexographic Printing

Flexographic printing is a widely used printing method, especially for printing materials such as packaging, labels and plastic films. In this printing method, the anilox roller plays a vital role.

(1) Working principle of flexographic printing

The core equipment of flexographic printing is the flexible printing plate, which is made of soft material (usually rubber or flexible polymer) and can efficiently transfer ink to uneven substrates. During the entire printing process, the anilox roller soaks the ink and transfers it accurately to the flexible printing plate, which then transfers the ink to the substrate (such as paper, plastic or other packaging materials).

The amount of ink that the anilox roller's cells can hold depends on the shape, size and distribution of the cells. The amount of ink transferred can also be adjusted by changing the characteristics of the anilox roller. This precise ink control enables flexographic printing to produce high-quality prints on substrates of different materials and shapes.

(2) The importance of anilox roller in flexographic printing

● Precise ink control: The success of flexographic printing depends largely on the ability of the anilox roller to accurately control the amount of ink transferred. Different printing tasks require different ink thicknesses, and the anilox roller ensures that the amount of ink transferred each time is consistent and controllable through its mesh structure.

● Efficient ink transfer: Flexographic printing is generally used for high-speed, large-volume printing tasks. The anilox roller is designed to maintain stable ink transfer at high speeds, ensuring uniformity and clarity of the printed image.

2. Gravure Printing

Gravure printing is a printing process that transfers ink from the grooves to the surface of the printing plate. Although the main feature of gravure printing is the reliance on the grooves for ink storage and transfer, the anilox roller also plays an important auxiliary role in this process, especially in the initial distribution and adjustment of the ink.

(1) Working principle of gravure printing

In gravure printing, the surface of the printing plate is engraved with multiple grooves, and the depth and shape of these grooves determine the amount of ink. When the printing plate contacts the substrate, the ink in the grooves is pressed onto the surface of the substrate, forming an image or text. In this process, the anilox roller is used to accurately distribute ink to the surface of the printing plate to ensure that each groove is filled with enough ink.

(2) The role of the anilox roller in gravure printing

Although the anilox roller is not a core component of gravure printing, it plays an auxiliary role in the distribution and control of ink. By using the anilox roller, printers can better regulate the amount of ink and ensure the consistency of printing quality.

3. Coating Printing

Coating printing refers to the printing process of achieving an image or texture by applying a layer of ink, coating or other functional liquid on the surface of the material. This process is often used to manufacture high-gloss packaging materials, plastic films or industrial products. The anilox roller is one of the most commonly used devices in coating printing, which is used to control and transfer precise amounts of coating materials.

(1) Working principle of coating printing

The core task of coating printing is to ensure the uniformity and consistency of the coating. The anilox roller distributes the coating evenly to the surface of the printing plate or material through the mesh on its surface. This precise coating control is crucial to the final quality of the product, especially when fine patterns or smooth surfaces are required.

(2) The role of the anilox roller in coating printing

● Uniform coating: The anilox roller ensures the uniform distribution of the coating material, so that the surface of the final product has a consistent thickness and texture. This is essential for certain high-demand products (such as packaging materials).

● Reduce waste: By using the anilox roller, the use of the coating can be precisely controlled, thereby reducing waste and improving production efficiency.

4. Pad Printing

Pad printing is a special printing process that transfers the pattern from the gravure printing plate to the surface of the substrate by using a silicone pad. The role of the anilox roller in pad printing is relatively small, but in some pad printing equipment, the anilox roller is still used to precisely control the distribution and transfer of ink.

(1) Working principle of pad printing

In the pad printing process, the anilox roller applies ink to the printing plate by rotating. The grooves on the printing plate store the ink, and then the pattern is "moved" from the printing plate to the surface of the substrate through the silicone pad. This process requires precise ink control. The anilox roller ensures that the ink can be accurately transferred to the printing plate and the integrity of the pattern is maintained through its unique structure.

(2) The auxiliary role of the anilox roller in pad printing

Although the core of pad printing relies on silicone pads and gravure printing plates, the anilox roller plays an auxiliary role in the initial ink distribution process. It ensures that the ink is evenly distributed in each groove of the printing plate, thereby ensuring the clarity and consistency of the pattern during the pad printing process.

How to choose the right anilox roller?

When using anilox roller for printing, it is crucial to choose the right anilox roller. Different printing processes and ink types require different cell shapes, sizes, and distribution densities. Here are some key factors to consider when choosing an anilox roller:

1. Cell size and depth

The size and depth of the cells determine how much ink the anilox roller can hold. For printing processes that require a thicker layer of ink, larger cells should be selected, while for high-precision, delicate printing effects, smaller, shallower cells should be selected.

2. Cell shape

The shape of the cells (such as square, diamond, or hexagon) has a great impact on the transfer and release properties of the ink. Certain cell shapes transfer ink more evenly, while other shapes may be more suitable for specific printing tasks.

3. Anilox roller material

Anilox rollers are usually made of ceramic or metal. Ceramic anilox rollers have better wear and corrosion resistance and are suitable for long-term use, while metal anilox rollers may be suitable for some cost-sensitive applications.

Industrial Roll Manufacturer Offering Customized Designs & Wholesale Prices

JH Machinery is a professional manufacturer of custom-designed industrial rolls that meet strict industry standards. Our product line includes cooling rolls, heating rolls, rubber rolls, and coated rolls suited for diverse industrial sectors. We supply directly from our 13,000 m² China factory with competitive wholesale prices and discounts for large orders. Our customized manufacturing ensures every roll fits your machinery perfectly. Contact us for a detailed quote and benefit from our prompt delivery and reliable after-sales service.