How does the industrial cooling roller control temperature?

In many industrial production processes, temperature control is crucial, especially in some areas that require precise processes and efficient production, such as plastic processing, metal processing, coating, paper processing, etc. Too high or too low temperature will not only affect production efficiency, but also affect product quality, and may even cause equipment damage. In order to solve this problem, the industrial cooling roller came into being. Cooling roller is an important equipment widely used in various manufacturing processes. With its efficient heat exchange performance, it can accurately control the temperature during the production process to ensure the stability of the production process and the quality of the product.

So, how does the industrial cooling roller control temperature? In this article, we will explore in depth the working principle, application field, performance characteristics and how to achieve efficient temperature control through reasonable design and configuration of the industrial cooling roller.

How does the industrial cooling roller control temperature?

The basic working principle of the industrial cooling roller is to control the temperature of the material or workpiece through heat exchange between the roller and the surrounding medium. In some production processes, especially in coating, printing, metal processing and other processes, the material or workpiece will be heated to a certain temperature during the processing. In order to prevent excessive temperature from affecting production, or to achieve solidification and curing of materials in certain processes, the application of cooling roller becomes very important.

Cooling roller usually controls temperature in the following ways:

1. Heat exchange principle

The most basic function of cooling roller is to reduce temperature through heat exchange. They usually come into contact with cooling medium (such as water or coolant), transfer heat to coolant through the roller surface, and then take away heat through the flow of coolant. After the coolant absorbs the heat from the roller surface, it takes away the heat through the external heat exchange system or cooling equipment (such as water cooler, cooling tower, etc.) to achieve the purpose of reducing temperature.

2. Selection and flow control of cooling medium

There are usually two options for the coolant flowing in the cooling roller: water or a specific coolant. In some high-temperature operations or special processes, the choice of coolant is very critical. Water as a cooling medium has good thermal conductivity and is a commonly used coolant; but in high-temperature or corrosion-risk environments, special coolants may be more suitable. Factors such as the flow rate, temperature and flow rate of the coolant have an important influence on the cooling effect. Therefore, controlling the flow and temperature of the coolant is one of the keys to achieving efficient temperature control.

3. Heat conduction and convection

The cooling roller transfers heat from the roller surface to the coolant by heat transfer. When the coolant passes through the roller surface, the heat is transferred from the roller to the coolant, and further removed by convection. The material of the roller surface (such as the thermal conductivity of the metal) has an important influence on the efficiency of temperature control. Metal materials with good thermal conductivity (such as copper, aluminum, steel, etc.) can effectively conduct heat and accelerate the cooling process.

4. Precise temperature control system

Many industrial cooling rollers are equipped with a precise temperature control system for real-time monitoring of the temperature of the roller surface and the coolant. Through sensors, temperature control valves, pumps, temperature control instruments and other equipment, the cooling roller can be adjusted according to the set temperature to ensure that the workpiece is always kept within the ideal temperature range during the processing process.

What are the application areas of industrial cooling rollers?

Industrial cooling rollers are widely used in many industries, mainly in those manufacturing processes that require precise temperature control. The following are several typical application areas:

1. Coating and printing industry

During the coating and printing process, the material usually needs to pass through the roller surface at high temperature to ensure the adhesion and curing effect of the coating. As the material passes through the hot roller surface, the temperature will gradually increase. The cooling roller can effectively reduce the temperature and help the coating or printing ink to solidify at an appropriate temperature, thereby ensuring the uniformity of the coating or printing effect.

● Control requirements: Control the temperature to prevent excessive temperature from causing excessive fluidity of the coating or ink, thereby affecting the quality of the product; or avoid excessively low temperature from causing incomplete solidification of the coating.

2. Metal processing industry

Metals often need to be heated during processing to increase their plasticity, and then need to be quickly cooled to increase their hardness or stability. The application of cooling rollers is crucial in metal heat treatment, rolling, stretching and other processes. Cooling rollers can quickly and effectively reduce the temperature of the metal surface, helping the metal to harden or shape quickly.

● Control requirements: Maintain the uniformity of the metal surface temperature to prevent deformation or cracking of the metal due to excessive temperature differences.

3. Plastic processing industry

In the processes of plastic extrusion and blow molding, the plastic material needs to go through a cooling stage after heating before it can solidify and form. Cooling rollers play a vital role in this process. They cool the surface of the plastic material to ensure that its shape is stable and the surface is smooth during the cooling process, and prevent defects in the plastic due to uneven cooling.

● Control requirements: Control the uniformity and speed of cooling to prevent bubbles or deformation on the plastic surface and ensure the appearance and dimensional stability of plastic products.

4. Paper and packaging industry

In the production process of paper, the pulp needs to be cooled quickly after heating and pressing to ensure that the paper can pass smoothly in the high-speed production line. The cooling roller helps it cool down quickly by contacting the surface of the paper to prevent deformation or adhesion of the paper due to excessive temperature. In the production of packaging materials, especially in the production of films, cooling rollers also play a similar role.

● Control requirements: Ensure the shape stability of paper and packaging materials during the cooling process to prevent warping and breakage caused by uneven cooling.

5. Food and pharmaceutical industry

Although the application of cooling roller in food and pharmaceutical industry is not as common as that in metal processing or plastic processing, cooling roller also plays a key role in some specific production processes. For example, in the coating and packaging process of medicine or food, cooling roller can help maintain the appropriate temperature to ensure the quality and safety of the product.

● Control requirements: Ensure that the product is not affected by excessive temperature during the cooling process, and avoid the product solidification or unevenness caused by too low temperature.

What are the factors affecting the cooling effect of cooling roller?

In order to ensure that the industrial cooling roller can effectively control the temperature, several key factors must be paid special attention and precisely adjusted:

1. Coolant flow and temperature

The flow rate and temperature of the coolant directly affect the cooling efficiency. If the flow rate of the coolant is too low, the heat is difficult to be taken away quickly; if the flow rate is too high, it may cause unnecessary energy waste. Therefore, precise control of the flow of coolant is the key to optimizing temperature control.

2. Roller surface material

The material and surface treatment of the roller surface have an important influence on the conduction of heat. For example, metals with high thermal conductivity, such as copper and aluminum, can conduct heat more efficiently, while rollers with smooth surfaces can reduce friction losses and improve cooling effects.

3. Design of cooling system

The design and configuration of the cooling system are crucial to the temperature control effect. Cooling rollers are usually equipped with efficient coolant circulation systems, temperature control valves and sensors to ensure that the temperature is always kept at the optimal state during the production process.

4. External environmental factors

In some extreme production environments (such as high temperature, humidity or polluted environments), the external environment may affect the cooling effect. For example, high air humidity may lead to unsatisfactory cooling effects and even evaporation and scaling of the coolant. Therefore, when designing the cooling system, it is also necessary to consider the impact of the external environment and take corresponding measures to compensate.

Maintenance and management of industrial cooling rollers

In order to maintain the cooling effect and long-term operation of the equipment, industrial cooling rollers need regular maintenance. Common maintenance work includes:

● Clean the coolant and roller surface: Clean the coolant regularly to prevent impurities from accumulating and maintain the cooling effect; at the same time, check whether the roller surface is worn or corroded, and repair it if necessary.

● Monitor temperature and flow: Use temperature sensors and flow meters to monitor the working status of the cooling system in real time to ensure that the cooling effect is always in the best condition.

● Check the cooling system: Regularly check the status of the coolant pump, pipes and valves to ensure the normal operation of the cooling system.

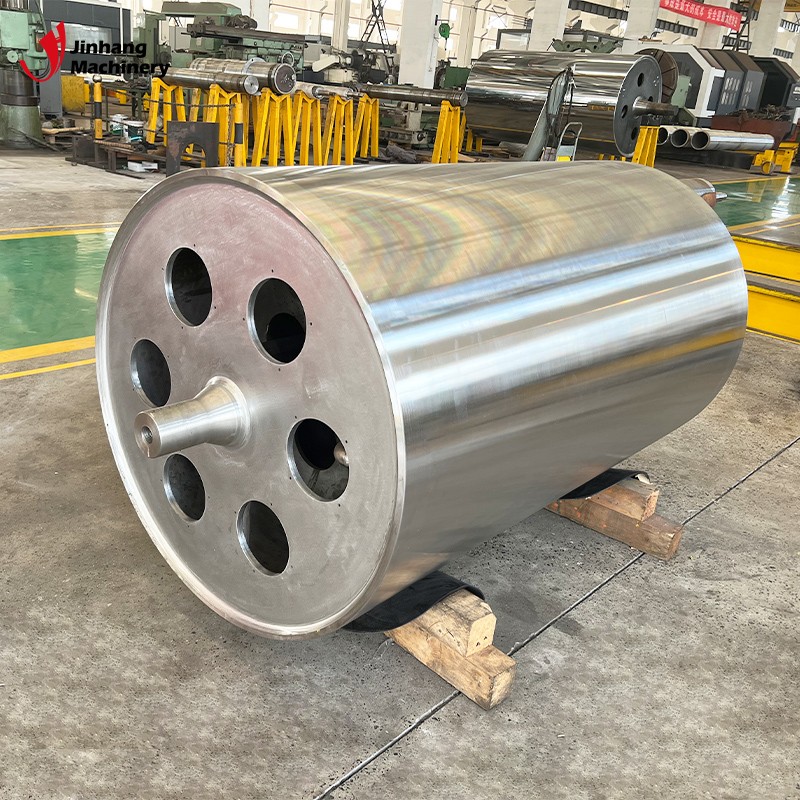

Reliable Supplier of Customized Industrial Rolls – High Quality & Competitive Prices

Jiangsu Jinhao Machinery Manufacturing Co., Ltd. (JH Machinery) has over 20 years of experience in producing high-quality industrial rolls. Our China-based factory specializes in custom designs tailored for metallurgy, packaging, and automotive industries. We supply rubber, polyurethane, tungsten carbide-coated, and ceramic-patterned rolls with precise manufacturing and affordable pricing. We provide wholesale discounts, flexible order quantities, and personalized quotes. Whether you need standard or highly specialized rolls, contact us today to buy from a trusted manufacturer offering excellent after-sales support and promotions.