How are industrial rollers customized and processed?

Industrial rollers, as an indispensable and important equipment in the production process of many industries, are widely used in steel, papermaking, plastics, rubber, printing, textiles and other fields. Whether in the process of steel plate rolling, paper calendering, rubber molding or plastic film extrusion, the quality and performance of industrial rollers are directly related to production efficiency, product quality and stable operation of equipment. Therefore, the customization and processing process of industrial rollers is crucial.

This article will discuss in detail the customization process, processing technology, material selection, surface treatment and quality control of industrial rollers to help readers gain an in-depth understanding of the production process of this key equipment.

Customization requirements and application background of industrial rollers

The customization requirements of industrial rollers come from the production processes and technical requirements in various fields. Different industrial applications have different requirements for the specifications, materials, hardness, surface treatment, etc. of rollers. The customization process of industrial rollers must be tailored according to these special requirements. Therefore, when customizing industrial rollers, the following key parameters must be clarified first:

● Use environment and working conditions: Different industrial environments have different requirements for rollers. For example, in the steel industry, industrial rollers need to withstand high temperatures, high pressures, and strong friction; while in the papermaking industry, industrial rollers need to be corrosion-resistant and wear-resistant. Understanding the environment and working conditions in which rollers are used is the first step in determining their design and manufacturing.

● Roller size and shape: The size of industrial rollers includes the length, diameter, bearing aperture, etc. of the rollers, and the shapes include cylindrical, conical, etc. When customizing, these size requirements must be accurately calculated and designed according to the specific production line requirements.

● Material and surface treatment: The material and surface treatment of industrial rollers will affect their service life, wear resistance, corrosion resistance and other properties. Different production processes have different requirements for roller materials. Some require the use of high-strength materials such as stainless steel and high-alloy steel, while others require surface treatment technologies such as chrome plating, spraying, and polishing.

● Load and pressure: Industrial rollers often withstand certain pressures and loads during operation. Therefore, the strength, hardness, and pressure resistance of rollers are key considerations in the customization process.

How is industrial roller customized and processed?

The customization and processing of industrial roller involves a series of precise process flows. From preliminary design, material selection, processing and manufacturing to surface treatment, each link needs to be strictly controlled to ensure that the final industrial roller meets the customer's technical requirements and usage standards.

1. Design stage

The customization of industrial roller starts with the design stage. The designer conducts the preliminary design of the roller according to the production requirements and technical specifications provided by the customer. At this stage, the following aspects need to be considered:

● Functional requirements: According to the customer's production process requirements, the shape, size, load capacity, speed, etc. of the roller are designed.

● Material selection: Select appropriate materials according to the working environment of the roller. Common materials include carbon steel, stainless steel, alloy steel, etc.

● Surface treatment requirements: According to the wear resistance and corrosion resistance requirements of the industrial roller surface, determine whether surface treatment is required, such as chrome plating, spraying, polishing, etc.

After the design plan is completed, simulation analysis and calculation are usually required to ensure that the roller will not have problems such as overload and deformation in actual work, and can operate stably for a long time.

2. Material procurement

According to the design requirements, choosing the right raw materials is a crucial step in the processing process. Common industrial roller materials include:

● Carbon steel: has good strength and hardness, suitable for applications in low-load, non-corrosive environments.

● Stainless steel: has excellent corrosion resistance and is suitable for food, chemical, papermaking and other industries.

● Alloy steel: such as chrome-molybdenum steel, chrome-manganese steel, etc., have higher strength and wear resistance, suitable for high-load, high-temperature, and high-pressure working environments.

● High wear-resistant materials: For some industries that require high wear resistance, materials such as cemented carbide and tungsten steel may need to be used.

When purchasing materials, it is necessary to ensure that the materials meet the quality standards and avoid using defective or non-compliant raw materials.

3. Machining

After the raw materials are prepared, the machining of industrial rollers enters the actual production stage. Common processing techniques include:

● Turning: The outer diameter, length and surface of the roller are precisely processed by a lathe to ensure the roundness, smoothness and dimensional accuracy of the roller.

● Grinding: Grind the surface of the roller carefully to obtain higher surface finish and dimensional accuracy. Grinding process is particularly important in applications that require high finish and high precision.

● Milling and drilling: Mill and drill where needed to make bearing holes, threaded holes, etc. to ensure that the roller can be installed on the production equipment.

During the entire processing process, high-precision CNC machine tools and tools are required to ensure that the dimensional accuracy and surface quality of the roller meet the design requirements.

4. Heat treatment and hardening

For some industrial rollers with high loads and high wear resistance requirements, heat treatment may be required to increase the hardness and strength of the material. Common heat treatment processes include:

● Normalizing: Improve the uniformity and strength of steel, usually used for rollers with medium loads.

● Quenching and tempering: By heating to high temperature and then cooling rapidly, and then tempering, the surface hardness of the roller is improved, which is suitable for environments with high loads and high wear resistance requirements.

● Annealing treatment: Reduce the internal stress of steel and increase its processability, which is suitable for rollers with lower hardness requirements.

The selection of heat treatment process needs to be precisely controlled according to the working environment and load requirements of the industrial roller to ensure that the roller has the required strength, hardness and durability.

5. Surface treatment

Surface treatment is an important part of improving the corrosion resistance, wear resistance and finish of industrial rollers. Common surface treatment processes include:

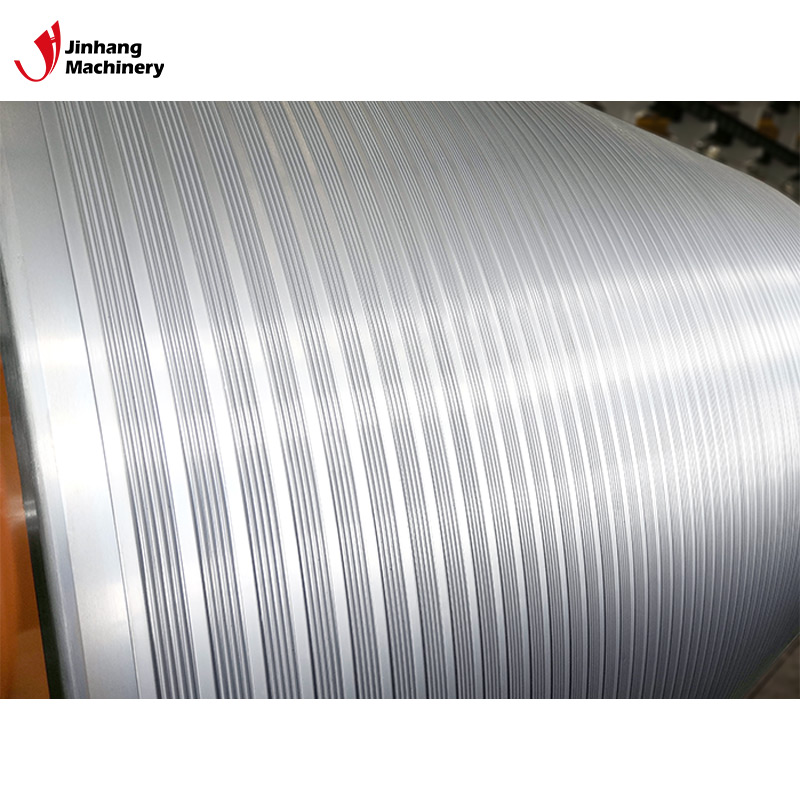

● Chrome plating: The chromium layer is attached to the surface of the roller through the electroplating process to improve its corrosion resistance, hardness and wear resistance. Especially in the steel, papermaking, printing and other industries, chrome-plated rollers are the most common choice.

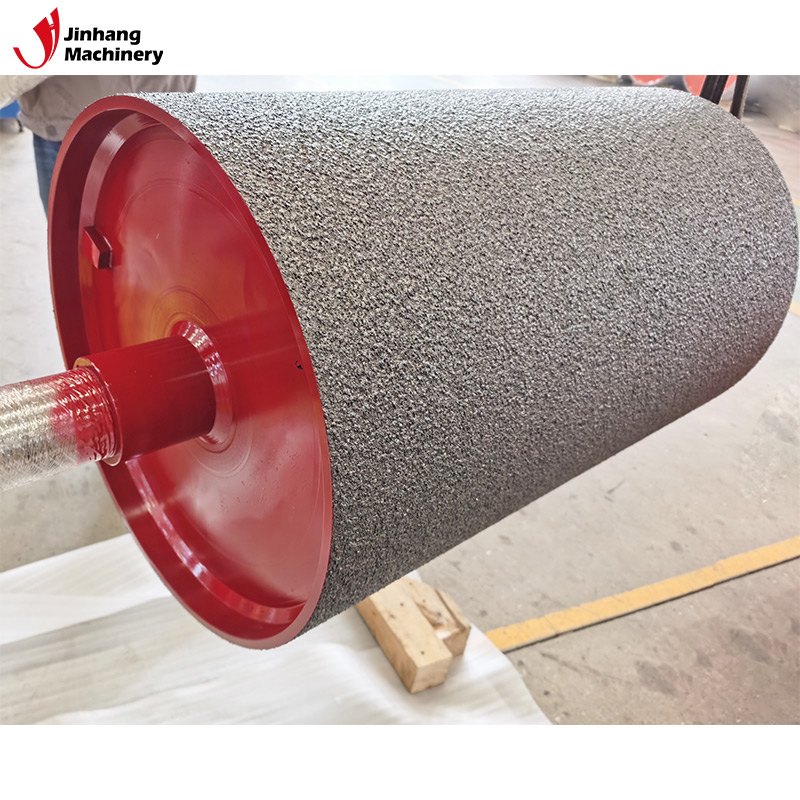

● Spraying: Spray a specific coating on the surface of the roller to form a protective film to prevent corrosion and wear.

● Polishing: Through mechanical polishing, the roller surface can achieve a high finish, reduce the friction coefficient, and improve the running performance of the roller.

● Thermal spraying: A layer of special material is coated on the surface of the roller using thermal spraying technology to improve the wear resistance and corrosion resistance of the roller.

The choice of surface treatment should be reasonably designed according to the specific application scenario and performance requirements of the roller to ensure that its performance is maximized.

6. Quality inspection

In the processing of industrial roller, quality control is a crucial link. Usually includes the following inspections:

● Dimension inspection: Check the dimensions of the roller with precision measuring tools to ensure that it meets the design requirements.

● Surface quality inspection: Check whether there are scratches, pores, cracks and other defects on the surface of the roller to ensure that the surface is smooth and defect-free.

● Hardness test: Test the hardness of the roller to ensure that it meets the hardness standard required by the design.

● Corrosion resistance test: Especially for rollers that require higher corrosion resistance, corrosion resistance tests such as salt spray tests are required.

Only through strict quality control can we ensure that the customized industrial roller can achieve the expected performance and service life in actual applications.

Challenges and solutions for industrial roller customization and processing

In the customization and processing of industrial rollers, there are often some technical challenges, such as material selection and matching, processing accuracy control, and surface treatment uniformity. To overcome these challenges, manufacturers usually adopt the following strategies:

● Advanced processing equipment: By using high-precision CNC machine tools, laser cutting equipment, precision grinders and other equipment, the processing accuracy is improved to ensure the quality of industrial rollers.

● Strict process control: During the production process, a detailed process flow is formulated to ensure that each link has clear operating standards and quality requirements.

● Optimized material ratio: According to different usage requirements, the most suitable material ratio and heat treatment process are selected to improve the comprehensive performance of the roller.

● Professional technical team: Relying on experienced technicians and engineers to ensure the rationality and feasibility of the industrial roller customization plan.

High-Precision Rolls Manufacturer with Customization & Competitive Pricing

At JH Machinery, we focus on manufacturing industrial rollers with top precision and durability. Our products include heating rolls, cooling rolls, mirror-finished rolls, and rubber rolls, suitable for multiple sectors like mining and printing. We use advanced Italian POMINI grinding machines and automatic welding equipment to ensure the highest standards. Buying directly from our factory means access to low prices, wholesale promotions, and bulk discounts. We also offer custom processing based on your drawings. Request a quote now and discover why we’re the preferred supplier for industrial rollers in China.