How to clean industrial ceramic anilox rollers?

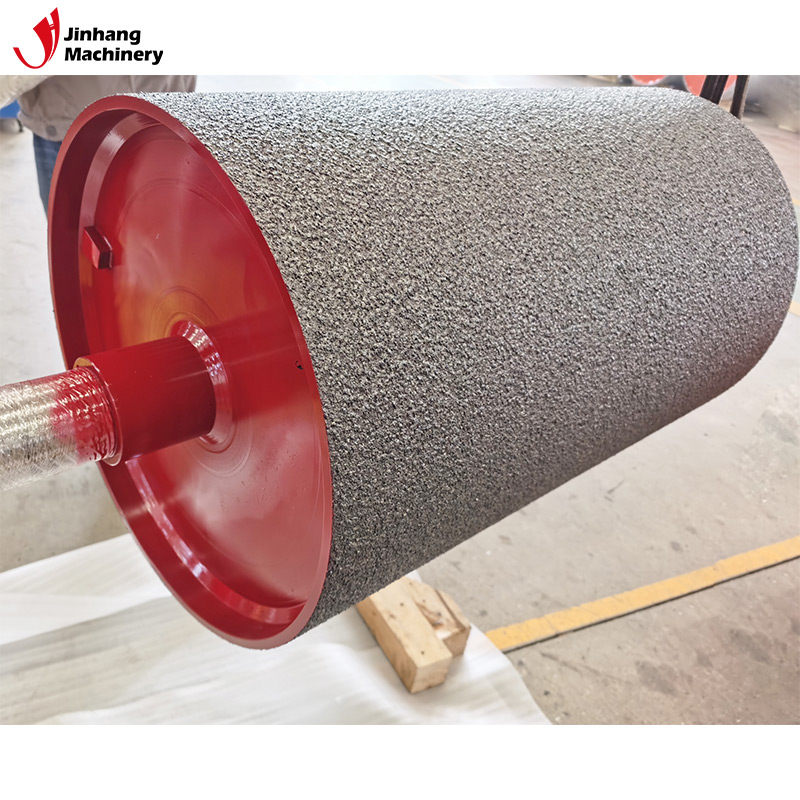

As a key equipment component in many manufacturing industries, industrial ceramic anilox rollers are widely used in printing, packaging, coating, papermaking and other industries. Due to the special reticulated structure on its surface, this roller can accurately control the transfer of liquid or viscous substances to ensure uniform and stable application effects. However, after long-term use, the surface of ceramic anilox rollers will accumulate ink, paint, glue and other substances, which will affect its working efficiency and product quality. Therefore, regular and effective cleaning of industrial ceramic anilox rollers is an important part of ensuring long-term stable operation of equipment.

This article will discuss in detail how to properly clean industrial ceramic anilox rollers to extend their service life and improve production efficiency.

What are the surface characteristics of ceramic anilox rollers?

Before discussing how to clean ceramic anilox rollers, understanding their surface characteristics is essential for choosing the right cleaning method. The surface of ceramic anilox rollers is made of hard ceramic material, and its reticulated structure is used to store and release fluids. These reticulate structures are usually very small and have various shapes, such as mesh and honeycomb. Due to the presence of these meshes, cleaning not only needs to remove surface residues, but also needs to go deep into these tiny meshes to clean. Therefore, cleaning ceramic anilox rollers is not as easy as simply wiping the surface.

The main features of ceramic anilox rollers include:

1. High hardness: Ceramic materials are very hard and have good wear and corrosion resistance.

2. Surface reticulation: The mesh structure of ceramic anilox rollers is fine, usually at the micron level, which makes its material transfer accuracy very high, but also increases the difficulty of cleaning.

3. Chemical stability: Ceramics are resistant to most chemicals, which means that a variety of cleaning solvents can be used without causing damage to the roller body.

What is the importance of cleaning ceramic anilox rollers?

During the production process, ceramic anilox rollers come into contact with various sticky substances, such as inks, coatings, glues, etc. If not cleaned in time, these substances will remain in the mesh and surface, gradually accumulate, and cause the following problems:

1. Uneven transfer: Residues in the mesh will block the reticulation structure, resulting in uneven material transfer and affecting the quality of the product.

2. Increased surface friction: Long-term accumulation of residues will increase the friction coefficient of the roller, reduce work efficiency, and increase energy consumption.

3. Production failure: In severe cases, residues will cause the ceramic anilox roller to jam, affecting the normal operation of the equipment, and even causing downtime and equipment damage.

Therefore, keeping the ceramic anilox roller clean will not only help improve production efficiency, but also extend the service life of the equipment.

How to clean industrial ceramic anilox rollers?

Depending on the different types of residues on the surface of the ceramic anilox roller, a variety of cleaning methods can be used. These methods include physical cleaning, chemical cleaning, and ultrasonic cleaning. The following are several common cleaning methods:

Manual cleaning

Manual cleaning is the most basic cleaning method for ceramic anilox rollers and is suitable for cleaning light surface residues. Commonly used tools include soft cloth, brushes, and cleaning solvents. The advantage of manual cleaning is that it is simple to operate and is suitable for daily maintenance and situations where surface contamination is light.

Steps:

● Dip a soft cloth or brush in an appropriate amount of cleaning solvent and gently wipe the surface of the anilox roller.

● For residues in the mesh, use a soft brush to lightly scrub to avoid damage to the roller surface.

● Rinse the roller with clean water to ensure that the solvent and residue are completely removed.

● Finally, wipe the surface with a clean cloth to avoid residual water stains.

Although manual cleaning is suitable for lightly contaminated rollers, it is not possible to thoroughly clean deep residues due to the small mesh holes, so it is suitable as part of daily maintenance.

Chemical cleaning

Chemical cleaning is a method of dissolving and removing residues in the mesh and surface of ceramic anilox rollers by using chemical solvents. It is suitable for more stubborn ink or paint deposits. Since ceramic materials have strong chemical corrosion resistance, a variety of cleaning solvents can be used, such as alcohol, isopropyl alcohol, thinners, etc.

Steps:

● Select a suitable chemical solvent according to the nature of the surface residue. Note that the chemical solvent should have strong dissolving power but should not corrode the ceramic anilox roller.

● Dip a soft cloth or brush into the chemical solvent and apply it evenly on the roller surface, especially the mesh area.

● Let it sit for a few minutes to allow the solvent to fully dissolve the residue.

● Use a brush to gently scrub the mesh and surface to ensure that the residue is completely removed.

● Finally, rinse the roller thoroughly with clean water and wipe the surface dry.

Chemical cleaning is suitable for more stubborn residues, but you need to make sure to use the appropriate solvent to avoid chemical damage to other parts of the equipment.

Ultrasonic cleaning

Ultrasonic cleaning is an efficient cleaning method, especially for cleaning residues inside the mesh that are difficult to reach. Ultrasonic cleaning uses tiny bubbles generated by high-frequency sound waves in the liquid. These bubbles generate a strong impact when they burst, which can effectively remove stubborn substances in the mesh of the ceramic anilox roller.

Steps:

● Place the ceramic anilox roller in the ultrasonic cleaning tank. The cleaning liquid can be water or a specific cleaning solvent.

● Start the ultrasonic cleaning device and set the appropriate frequency and time.

● During the cleaning process, the ultrasound will generate bubbles to impact the inside of the mesh and remove deep residues.

● After cleaning, rinse the roller with clean water to ensure that there is no detergent residue on the surface.

● Wipe the roller dry with a clean cloth or let it dry naturally.

Ultrasonic cleaning is suitable for cleaning ceramic anilox rollers with complex structures. It can completely remove deep stubborn residues, but due to the high cost of the equipment, it is usually used in cleaning situations that require high precision.

Laser cleaning

Laser cleaning is a non-contact cleaning method that uses a high-energy laser beam to irradiate the surface and instantly remove residues. Laser cleaning technology does not require the use of chemical solvents and will not cause wear on the ceramic surface. It is particularly suitable for cleaning stubborn ink stains or paint deposits.

Steps:

● Use dedicated laser cleaning equipment and adjust the appropriate laser intensity.

● Aim the laser beam at the surface of the roller and gradually scan the entire reticulated area.

● The laser energy will vaporize or decompose the residue, leaving a clean ceramic surface.

● After cleaning, no additional rinsing or drying steps are required.

The advantages of laser cleaning are high efficiency and environmental protection, no use of any chemicals, and suitable for situations with high precision requirements, but its equipment cost is high and is suitable for large enterprises or professional cleaning service providers.

What are the issues that need to be paid attention to during the cleaning of ceramic anilox rollers?

Although ceramic materials are resistant to chemical corrosion, it is still necessary to select suitable cleaning solvents to avoid the impact of corrosive chemicals such as strong acids and alkalis on other parts of the equipment. Secondly, although ceramic anilox rollers have high hardness, hard brushes or excessive friction should be avoided during cleaning to prevent the surface texture of ceramic anilox rollers from being damaged. In addition, regular cleaning is the key to maintaining long life and efficient operation of equipment. Enterprises should formulate reasonable cleaning cycles according to production conditions to avoid excessive accumulation of residues.

Buy Customized Industrial Rolls with OEM & After-Sales Service

JH Machinery is your reliable source for customized industrial rolls. We supply rolls tailored to your specific machinery requirements, including carbonized coatings and ceramic surface patterns. With ISO9001 certification and a modern 13,000 m² factory, we ensure quality and quick turnaround. We offer competitive prices with discounts on bulk orders, helping you reduce procurement costs. Our professional after-sales service guarantees free repair or replacement within warranty for any quality issues under specified conditions. Contact us today for wholesale pricing and fast delivery.