How to manufacture industrial tungsten carbide rollers?

Tungsten carbide rollers are important tools in the modern metal processing industry, especially in the fields of steel smelting, rolling, plastic processing, etc. Tungsten carbide rollers are widely used in various rolling mills due to their high hardness, high wear resistance and excellent thermal stability. The manufacture of tungsten carbide rollers involves multiple links such as material selection, process design, and processing technology. This article will discuss in detail how to manufacture industrial tungsten carbide rolls and analyze the key steps and technical requirements.

What is a tungsten carbide roller?

Tungsten carbide rollers usually refer to rollers made of cemented carbide materials (such as tungsten-cobalt alloys, tungsten-carbon alloys, etc.). Cemented carbide has excellent wear resistance, high temperature resistance and corrosion resistance, which makes it show extremely high efficiency and long service life in the metal processing process, especially in the fields of steel rolling and aluminum processing.

The application of tungsten carbide roller can be summarized into the following categories:

● Steel rolling: tungsten carbide roller is often used in hot rolling, cold rolling and seamless steel pipe production.

● Aluminum processing: tungsten carbide roller is more and more widely used in the hot rolling and cold rolling process of aluminum.

Processing with high wear resistance requirements: tungsten carbide roller is suitable for some processes with high requirements on roller wear resistance, such as strict requirements on roller surface wear.

What are the material options for tungsten carbide roller?

The core technology of tungsten carbide roller lies in its material selection. The main components of cemented carbide materials are usually alloys of tungsten, carbon, cobalt, nickel and other elements. Different composition combinations and different production processes will affect the performance of tungsten carbide roller, and then affect its processing efficiency and service life. Below we will focus on several commonly used materials for tungsten carbide roller.

● Tungsten cobalt alloy: Tungsten cobalt alloy is one of the most commonly used materials in tungsten carbide roller. Tungsten is the main component of cemented carbide, with extremely high hardness and wear resistance; while cobalt is mainly used as a binder, with good toughness and high temperature resistance. By controlling the ratio of tungsten to cobalt, alloys with different hardness and toughness can be obtained to adapt to different working conditions.

● Tungsten carbon alloy: Tungsten carbon alloy has higher hardness, but its toughness is slightly inferior to tungsten cobalt alloy, and is mainly used in some high wear resistance applications.

● Nickel-based alloy: In some high temperature and high pressure environments, nickel-based alloy has excellent corrosion resistance and wear resistance, and is used in some special tungsten carbide rollers.

● Other alloy materials: With the advancement of technology, some new alloy materials have gradually entered the manufacture of tungsten carbide rollers, such as molybdenum-based alloys, chromium alloys, etc.

What is the manufacturing process of tungsten carbide rollers?

The manufacture of tungsten carbide rollers is a complex process, involving multiple links from the selection of raw materials to the inspection of finished rollers. The following are the main steps in the manufacture of tungsten carbide rollers.

1. Preparation of alloy powder

The manufacture of tungsten carbide roll first requires the preparation of suitable powder, which is usually prepared by powder metallurgy technology. The preparation of cemented carbide powder is a key link in determining the quality of the final product. Common powder preparation methods include:

● Ball milling: Grind tungsten, cobalt, carbon and other raw materials into powder through a ball mill. During the ball milling process, the uniformity of the alloy composition and the particle size of the powder need to be controlled to ensure the performance of the final cemented carbide.

● Airflow milling: The powder is impacted and rubbed by high-pressure airflow to further disperse it into the required particle size.

● Chemical reduction method: Used to prepare high-purity tungsten powder, cobalt powder, etc. to ensure the purity of the alloy composition.

2. Mixing and pressing of alloy powder

After the alloy powder is prepared, the powders of different components need to be accurately mixed according to the design requirements. The mixed powder will be fed into the pressing machine, and the powder will be pressed into a blank of a predetermined shape by high pressure. During the pressing process, the temperature and pressure need to be precisely controlled to ensure that the alloy powder is fully combined and to avoid the formation of pores and cracks.

3. Sintering process

The pressed blank needs to go through the sintering process to make its density and hardness reach the required level. The sintering process is to diffuse and fuse the powder particles through high temperature treatment to form a dense cemented carbide structure. The sintering temperature is usually between 1400℃-1600℃, and the sintering atmosphere is generally hydrogen or argon to prevent oxidation reaction.

During the sintering process, the composition and porosity of the alloy will change, so it is necessary to accurately control parameters such as temperature, atmosphere and time. The sintered alloy has good density and high hardness, laying the foundation for subsequent processing.

4. Roughing and finishing

Although the sintered tungsten carbide roller blank has the basic hardness and density, the shape and size have not yet reached the requirements, so roughing and finishing are required.

● Roughing: mainly through turning, milling and other mechanical processing methods to remove excess material to form a workpiece close to the final shape. During roughing, special attention should be paid to prevent material damage caused by high temperature or improper operation.

● Finishing: Through precision machining techniques such as grinding and lapping, the tungsten carbide roller's dimensions, surface finish and surface hardness meet the final standards. During the finishing process, the selection of coolant and the adjustment of machining parameters are crucial to the machining quality.

5. Surface treatment and strengthening

After finishing, the surface quality of the tungsten carbide roller usually needs to be further optimized, especially under some high-load and high-speed working conditions. Surface treatment is the key to improving roller performance. Common surface treatment methods include:

● Heat treatment: Through further high-temperature heating and cooling processes, the internal structure of the tungsten carbide roller is adjusted to improve its hardness and wear resistance.

● Carburizing: Infiltrate carbon into the surface layer to form a high-hardness surface layer, thereby improving the wear resistance of the tungsten carbide roll.

● Coating technology: Some high-end tungsten carbide rollers are coated with a layer of metal ceramic coating to improve corrosion resistance and wear resistance.

6. Finished product inspection

After the tungsten carbide roller is processed, it needs to be strictly inspected to ensure that its size, hardness, surface quality, etc. meet the technical requirements. Common inspection items include:

● Dimension measurement: Use precision instruments to measure the diameter, length, surface roughness, etc. of the tungsten carbide roller.

● Hardness test: Use a microhardness tester or other hardness test methods to ensure that the tungsten carbide roll reaches the designed hardness.

● Surface inspection: Check whether there are defects such as cracks and pores on the surface.

● Wear resistance test: Test the wear resistance of the roller through wear resistance tests in simulated working environments.

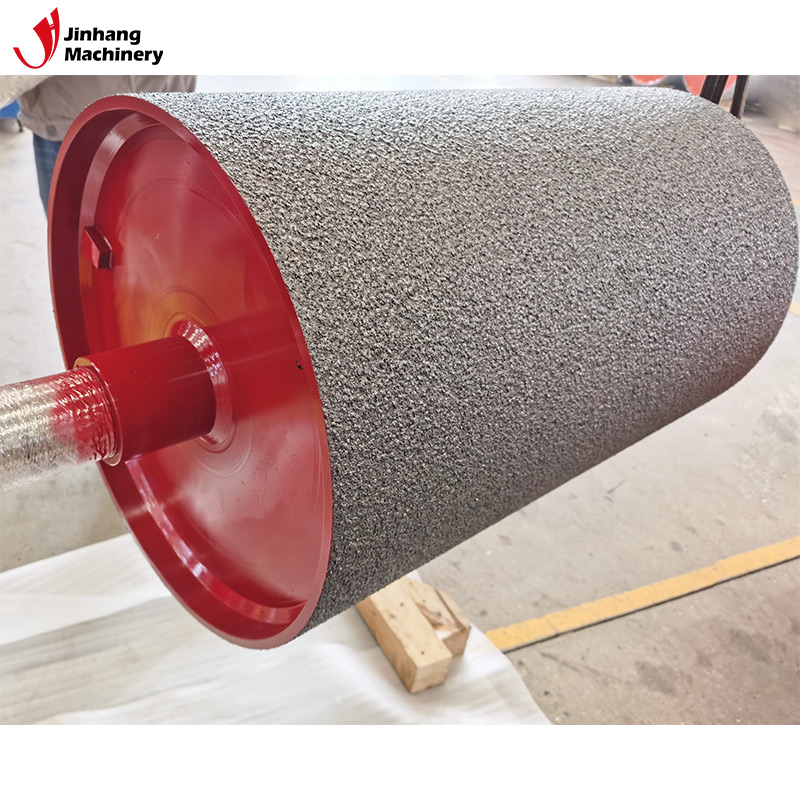

Looking for affordable, high-quality industrial rolls?

JH Machinery offers custom-engineered rolls made from rubber, polyurethane, or tungsten carbide coatings, ideal for metallurgy, packaging, and automotive testing. We use advanced machinery to guarantee precision and durability. Our factory provides flexible order quantities, discounts for bulk purchases, and competitive pricing directly from China. Partner with us for cost-effective rolls and excellent customer service.