What is the ratio of anilox roller to plate screen count?

In the printing industry, anilox roller is one of the key components that affect printing quality. Its main function is to transfer and control the amount of ink through tiny mesh holes on the surface. The ratio between the screen count of anilox roller (lines per inch, LPI) and the screen count of printing plate directly affects the quality of printed products, especially the ink transfer efficiency and the detail performance of printing. Therefore, understanding the reasonable ratio of the screen count of anilox roller to the screen count of printing plate is crucial to optimize printing effect and improve product quality.

This article will discuss in detail the relationship between the screen count of anilox roller and the screen count of printing plate, the calculation method of the ratio between the two, and its impact on the printing process. Through in-depth analysis of these issues, it helps printing practitioners make more reasonable equipment selection and process adjustments in actual production.

What is the screen count of anilox roller?

The screen count of anilox roller refers to the number of tiny mesh holes per inch on the surface of anilox roller, usually in LPI (lines per inch). The higher the screen count, the more meshes are distributed per unit area, and the smaller the meshes are; the lower the screen count, the larger the meshes are, and the greater the ink storage capacity. The main function of anilox roller is to control the amount of ink transfer, so the selection of screen count needs to be determined according to different printing requirements.

Generally speaking, anilox rollers with lower screen counts are suitable for rough printing, such as packaging printing or large-area color block printing, because these occasions require a larger amount of ink. Anilox rollers with higher screen counts are suitable for printing with rich details and high color requirements, such as labels, newspapers and magazines, because these occasions require more sophisticated ink control.

What is the screen count of a printing plate?

The screen count of a printing plate refers to the number of dots per inch of the printed image, also in LPI (lines per inch). The screen count of a printing plate directly affects the resolution of the image and the clarity of the printed product. The higher the screen count, the richer the details of the image, but the requirements for printing equipment are relatively high; the lower the screen count, the fineness of the printed image may decrease, but it can better handle large areas of color blocks or simple patterns.

In printing technologies such as flexographic printing, gravure printing, offset printing, etc., the screen count of the printing plate has an important influence on the color reproduction, clarity and layering of the final printed product. Therefore, in actual production, the selection of the screen count of the printing plate needs to be combined with the specific requirements of the printed product, which must not only ensure the details of the image, but also match the transmission capacity of the ink.

What is the ratio of the screen count of the anilox roller to the screen count of the printing plate?

In the printing process, the ratio between the screen count of the anilox roller and the screen count of the printing plate directly affects the transfer efficiency of the ink and the quality of the printed product. Usually, this ratio is determined by experience and industry standards. The common rule of thumb is: the screen count of the anilox roller should be 4 to 6 times the screen count of the printing plate.

The basis of this ratio is:

1. Ink control: If the screen count of the anilox roller is too low, the relatively large mesh will store too much ink, resulting in the inability to accurately control the ink when it is transferred to the printing plate, thus affecting the clarity and detail of the printed product. On the contrary, if the screen count of the anilox roller is too high and the mesh is too small, the ink storage and transfer capacity is insufficient, which may cause the printed product to be not full of color or the image to be unclear. Therefore, maintaining a ratio of 4 to 6 times helps to strike a balance between ink storage and transfer.

2. Printing effect: When the screen count of the printing plate is high, it means that the printed image requires more precise ink control. At this time, it is necessary to select an anilox roller with a high screen count to match the fineness of the printing plate to ensure that the ink can be evenly and appropriately transferred to each dot of the printing plate. When the screen count of the printing plate is low, it is suitable to use an anilox roller with a lower screen count, which can provide more ink and ensure the printing effect of large-area color blocks or simple graphics.

Practical application of specific ratios

In actual printing, different printing types and product requirements will affect the selection of anilox roller screen count and plate screen count. The following are some common screen count ratio choices:

1. Large area color block printing

For large area color block printing or images requiring lower resolution (such as outdoor advertising, packaging boxes, etc.), the screen count of the plate is usually low (60-100 LPI). In this case, the screen count of the anilox roller can be selected at a relatively low value, such as 200-400 LPI. This type of printing requires a large amount of ink, and the low-screen anilox roller can provide sufficient ink transfer to ensure uniform coverage of the color blocks.

Ratio recommendation: The screen count of the anilox roller is about 3-5 times the screen count of the plate.

2. Medium resolution printing

For printed products with medium resolution requirements, such as common magazines, leaflets, labels, etc., the screen count of the plate is usually 100-150 LPI. In this case, choosing an anilox roller with 400-600 LPI can ensure that the ink can be evenly transferred while ensuring the details, avoiding the problem of too much or too little ink.

Ratio recommendation: The screen count of the anilox roller is about 4-6 times the screen count of the printing plate.

3. High-resolution printing

For high-resolution printed products, such as high-end advertising brochures, fine packaging, etc., the screen count of the printing plate is usually higher (150-300 LPI). This type of printing requires the anilox roller to have extremely high precision to ensure that the ink can be accurately controlled and evenly distributed. Therefore, the screen count of the anilox roller should be above 600 LPI, or even up to 1000 LPI, to match the high-resolution requirements of the printing plate.

Ratio recommendation: The screen count of the anilox roller is about 5-6 times the screen count of the printing plate.

4. Special process printing

In some special printing processes, such as flexographic printing and gravure printing, multi-color printing or special inks (such as metallic colors, fluorescent colors, etc.) may be involved. At this time, the ratio of the anilox roller to the screen count of the printing plate needs to be adjusted according to the specific process requirements. In order to ensure the transmission of these special inks, the screen count ratio may be slightly different.

How to choose the right screen count ratio?

In printing production, choosing the right anilox roller and the screen count ratio of the printing plate needs to consider many factors, including the fineness of the printed image, the viscosity of the ink, the performance of the printing equipment, and the purpose of the printed product. The following suggestions can help printing practitioners make a better choice:

1. Printing requirements: First, the purpose and requirements of the printed product should be clarified. If it is fine image printing, a higher screen count ratio should be selected; if it is large-area color block printing, a lower ratio should be selected.

2. Equipment performance: Different printing equipment has different requirements for ink transmission and the selection of anilox roller. When selecting the screen count ratio, it is necessary to debug according to the actual situation of the equipment to ensure that the best printing effect can be obtained.

3. Ink characteristics: Different types of inks have different viscosities and fluidities. In the selection of the screen count ratio, appropriate adjustments should be made according to the characteristics of the ink. High viscosity inks may require lower screen counts, while low viscosity inks are suitable for anilox rollers with higher screen counts.

4. Experience and testing: Although there are many rules of thumb about screen count ratios in the industry, in actual production, printing effects often need to be optimized through continuous testing and adjustment. Therefore, it is recommended that printers verify the appropriateness of the screen count ratio through small batch testing during production.

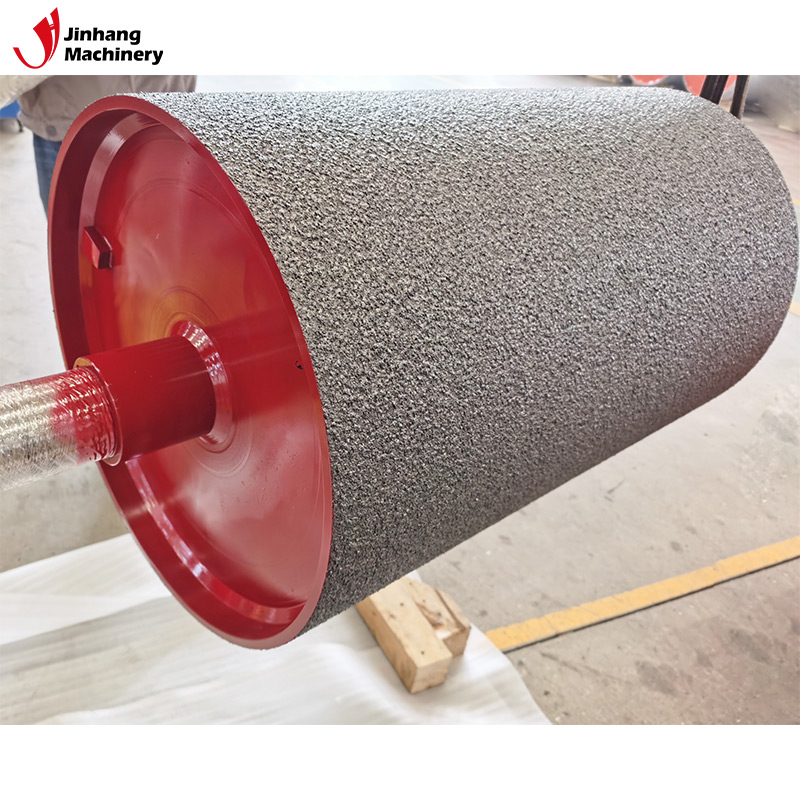

Wholesale Industrial Rolls Factory with Custom Processing Capability

JH Machinery is a leading factory specializing in industrial rolls with custom processing services. We manufacture various types of rolls, including electroplated, mirror-finished, and ceramic anilox rollers that suit different industrial applications. Our advanced equipment, such as CNC lathes and dynamic balancing machines, guarantees high precision and consistency. For bulk buying or tailor-made rolls, contact our sales team and get a fast, reliable quote today.