How does the porosity of industrial ceramic anilox roller affect ink transfer?

In the printing industry, ceramic anilox rollers are widely used in the process of ink transfer, especially in the fields of flexographic printing and offset printing. The structural characteristics and properties of ceramic anilox rollers have a crucial impact on the distribution, transfer and final printing quality of ink. Among them, porosity, as one of the important parameters of ceramic anilox rollers, plays a direct and decisive role in the effect of ink transfer.

This article will explore in depth how the porosity of industrial ceramic anilox rollers affects the ink transfer process, analyze the relationship between porosity and ink transfer effect, reveal its impact on printing quality, production efficiency and cost control, and discuss how to optimize porosity to improve printing quality. Through these analyses, this article aims to provide engineers, technicians and production managers in the printing industry with deep insights into the porosity of ceramic anilox rollers, helping them make more accurate choices and adjustments in actual production.

What is a ceramic anilox roller?

Ceramic anilox roller is a key component for ink transfer in printing machinery. Its surface is covered with a special ceramic coating and a regular grid-like pore structure is formed on the surface. This pore structure can effectively store and release ink, and transfer ink from the ink pool to the printing material during the printing process. Ceramic anilox roller has been widely used in many high-demand printing occasions due to its wear resistance, corrosion resistance and stable working performance.

How does the ceramic anilox roller work?

The working principle of the ceramic anilox roller mainly depends on the reticulated structure on the roller surface. These pores (commonly referred to as "reticulated holes") can store ink and transfer ink to the printing medium under appropriate pressure. The design of the reticulated structure determines the size, shape and distribution of the pores, which affects the adsorption, storage amount and uniformity and accuracy of the ink release.

In actual work, the ceramic anilox roller is used in conjunction with other rollers (such as rubber rollers, steel rollers, etc.) to complete the transfer and distribution of ink through mutual friction and pressure adjustment. The ink is squeezed out of the pores of the anilox roller and evenly transferred to the substrate, thus forming a stable printing effect.

What does the porosity of industrial ceramic anilox roller mean?

Porosity refers to the ratio of the pore volume to the overall volume of the material. In ceramic anilox roller, porosity refers to the ratio of the total volume of pores on the roller surface to the total surface area of the roller surface. The level of porosity directly affects the ink storage capacity, transfer ability and printing effect.

The porosity of ceramic anilox roller is usually controlled by factors such as pore size, depth, and distribution density. Porosity that is too low or too high will affect the ink transfer effect and printing quality. Therefore, optimizing the porosity to achieve the best ink transfer effect has become an important technical goal in the production process.

Factors affecting porosity

The porosity of ceramic anilox roller is affected by multiple factors, including:

● Roller surface design: The size, shape and distribution density of the roller surface pores will directly affect the porosity. Different types of reticulation designs can lead to different porosities, which will affect ink transfer.

● Ceramic material properties: The composition, hardness, wear resistance and density of ceramic materials also affect porosity. The porosity of ceramic anilox rollers may vary under different material and coating conditions.

● Manufacturing process: The manufacturing process of ceramic anilox rollers, especially sintering temperature, coating thickness and subsequent treatment methods, will affect the formation and distribution of pores.

● Use conditions: Wear, chemical corrosion and environmental factors on the roller surface during long-term use may also cause changes in porosity, which in turn affects the ink transfer effect.

How does the porosity of industrial ceramic anilox rollers affect ink transfer?

Relationship between porosity and ink storage capacity

Porosity directly determines how much ink a ceramic anilox roller can store. Higher porosity usually means that the roller surface has more ink storage space and can therefore store more ink. This is crucial for the uniformity and stability of ink transfer, especially when printing on large areas or at high speeds.

However, if the porosity is too high, it may also lead to excessive ink storage, which in turn affects the release and distribution of ink. Excessive ink may cause ink accumulation during the printing process, resulting in unclear printed images or ink overflow. Therefore, the appropriate porosity needs to be adjusted according to the specific printing process and ink type.

Porosity and uniformity of ink transfer

The porosity of the ceramic anilox roller also affects the uniformity of ink transfer. When the porosity is high, the pores of the anilox roller may store too much ink, resulting in uneven ink distribution and printing defects. On the contrary, too low a porosity may result in insufficient ink storage capacity on the roller surface, thereby affecting the ink transfer effect and causing the printed image to be too light or uneven.

The ideal porosity should stabilize the ink transfer process and ensure that the ink can be evenly distributed on the surface of the printed material, so as to ensure the consistency of printing quality.

Porosity and ink type compatibility

Different types of inks have different requirements for porosity when using ceramic anilox rollers. For example, water-based inks, solvent-based inks, and UV inks have different rheological properties, and these inks require different porosities when in contact with ceramic anilox rollers. Water-based inks usually require higher porosity because they have lower viscosity and stronger fluidity, and higher porosity can effectively store and release these inks. For solvent-based inks with higher viscosity, moderate porosity helps ensure stable transfer and uniform distribution of ink.

Porosity and ink fluidity

The fluidity of ink is closely related to the porosity of the ceramic anilox roller. Higher porosity usually means larger pores that can accommodate more ink, which may affect the fluidity of the ink. Too high porosity may cause ink retention during the transfer process, affecting fluidity and thus affecting the rapid transfer of ink. Lower porosity may cause the ink to be released prematurely or not fully transferred, resulting in problems with printing quality.

How to optimize the porosity of ceramic anilox roller?

It is crucial to select the appropriate porosity range according to the specific printing process requirements and ink type. Generally, the type of ink, printing speed and type of material will affect the choice of ceramic anilox roller porosity. For example, in flexographic printing, higher porosity helps improve the stability and uniformity of ink transfer, while in offset printing, the appropriate porosity may need to be selected according to the printing quality requirements to avoid ink overflow and image blur.

Control porosity uniformity

To ensure uniform ink transfer, the porosity distribution of the ceramic anilox roller must be uniform. If the porosity distribution is uneven, it may cause excessive or insufficient ink transfer in local areas, thus affecting the printing quality. During the production process, it is necessary to ensure the uniformity of porosity across the roller surface through a sophisticated manufacturing process.

Rationally select ceramic materials

Different ceramic materials have different porosity characteristics, and selecting the right ceramic material can also optimize the porosity. Some ceramic materials have higher density and can achieve lower porosity but still maintain good ink transfer performance; while some materials may have higher porosity, but their ink transfer performance may also be more stable. Therefore, selecting the right material is very important for optimizing the porosity of the anilox roller.

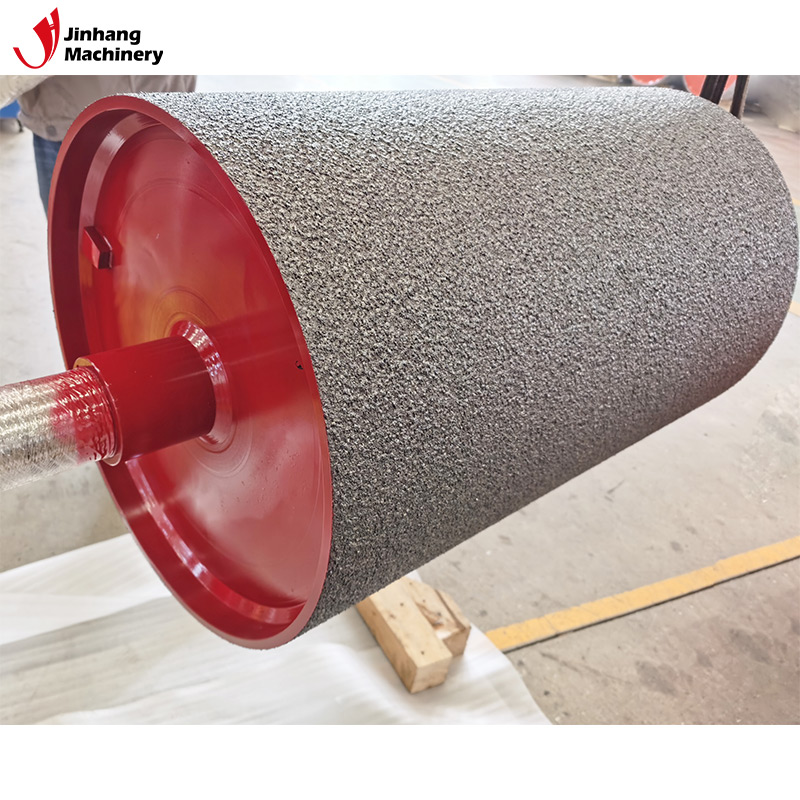

Quality Rolls Supplier from China – Custom & Bulk Discounts

As a premier rolls manufacturer in China, JH Machinery delivers a wide variety of high-quality industrial rolls with customized designs. Our products include cooling rolls, heating rolls, rubber rolls, and tungsten carbide-coated rolls designed to meet industry-specific needs. We have a 13,000 m² production facility equipped with advanced grinding and welding machines to ensure precision. Get in touch for quotes, promotions, and special purchasing plans tailored for your business.