Can Roller Manufacturers Customize Products Based On Drawings?

In modern industrial production, roller equipment is present in almost all continuous material processing scenarios. For example, production lines for plastic film, papermaking, textiles, printing, metal rolling, rubber, composite materials, and electronic materials all rely on various functional rollers, including rubber rollers, heating rollers, mirror rollers, cooling rollers, corona-plated rollers, chrome-plated rollers, tungsten carbide-coated rollers, and many custom-designed rollers with special structures.

Due to significant differences in equipment structure, material properties, process requirements, and dimensional standards, companies often need to customize rollers based on actual production drawings, rather than directly using general-purpose standard parts. Therefore, many purchasing personnel or engineers have a key question:

Can roller manufacturers customize products based on drawings?

The answer is very clear: Yes, and professional roller manufacturers often possess complete customization capabilities.

Especially high-quality industrial roller manufacturers like Jinhang Machinery in China, which can not only strictly manufacture according to drawings but also perform engineering design and technical optimization based on equipment requirements to meet various precision, high-temperature, wear-resistant, insulating, corrosion-resistant, and special surface treatment requirements.

This article will provide a professional analysis, systematically examining aspects such as "Do roller manufacturers have customization capabilities?", "Why must rollers be manufactured according to drawings?", "What can roller manufacturers customize?", and "How to judge the true strength of a roller manufacturer?" to help you understand why industrial rollers almost always require customization and the precision and range that professional roller manufacturers can achieve.

Why must industrial rollers be customized according to drawings?

To understand "Can roller manufacturers customize according to drawings?", we must first answer a more core question: Why do industrial rollers almost always need to be manufactured according to drawings?

The reasons are as follows:

1. Roller size standards are completely different for different equipment

Even for similar equipment, such as extruders, casting machines, coating machines, rolling mills, and printing machines, different brands, structures, and production capacities will have completely different roller specifications:

• Total length

• Working surface length

• Shaft diameter

• Mounting interface

• Load-bearing structure

• Center distance

• Wall thickness

• Weight

• Surface treatment requirements

Therefore, general-purpose rollers are almost impossible to match with industrial equipment, making customization inevitable.

2. The process conditions differ for each production line

For example, heat treatment temperature, tension, material hardness, and operating speed all necessitate customized roller structures.

High-temperature conditions require:

• Heated rollers/heat-conducting oil rollers

• Special thermal expansion coefficient design

• Thickened substrate structure

High-speed conditions require:

• High dynamic balance level

• Higher rigidity

• Higher installation accuracy

Different process conditions directly affect the roller structure; therefore, custom drawings are essential.

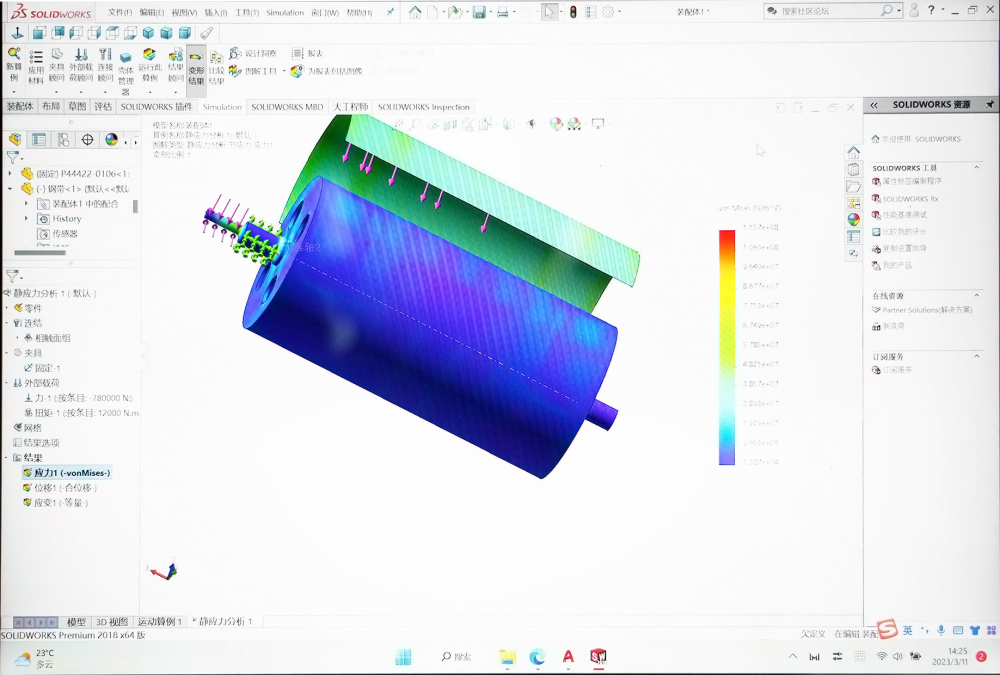

3. Industrial rollers require extremely high machining precision

For example, certain mirror rollers, cooling rollers, and tungsten carbide rollers require the following precision:

• Circular runout 0.002mm

• Roughness Ra0.005

• Extremely high roundness

• Surface hardness customized according to specific process requirements

These requirements must be met according to the drawings; otherwise, production quality requirements cannot be achieved.

4. High Diversity of Internal Roller Structures

For example:

• Heating rollers require internal spiral flow channels

• Cooling rollers require water channel design

• Corona-treated rollers require insulation layers and special skins

• Mirror-finish rollers require high-precision plating

• Chrome-plated rollers require standard plating thickness

• Tungsten carbide rollers require multi-layer spray coating structures

These cannot be replaced with standard rollers and must be designed according to drawings.

5. Drawings Guarantee Interchangeability and Installation Stability

Industrial equipment downtime costs are high; therefore, drawing-based fabrication ensures:

• Quick assembly when changing rollers

• Perfect matching with chain drives, gear systems, and bearing housings

• Complete consistency in allowances, locking structures, etc.

Therefore, drawing-based fabrication is not only feasible but also the only correct approach.

Do roller manufacturers truly possess the capability to fabricate according to drawings?

Truly professional roller manufacturers possess complete customization capabilities and can reproduce roller structure requirements from drawing information.

For example:

• Substrate type

• Heat treatment method

• Surface treatment process

• Internal structure

• Dynamic balance grade

• Tolerance standards

• Assembly method

• Coating thickness and hardness

This requires roller manufacturers to possess complete equipment and process capabilities in machining, heat treatment, coating, dynamic balancing, and testing.

Therefore, excellent roller manufacturers can not only complete the processing of drawings but also professionally review them to ensure they meet manufacturing requirements.

What types of industrial rollers can roller manufacturers customize?

A high-quality roller manufacturer can produce a very wide range of rollers, typically including:

• Industrial rubber rollers

• Heated rollers/Heat-conducting oil rollers

• Cooling rollers/Water-cooled rollers

• Mirror-finish rollers

• Corona rollers

• Chrome-plated rollers

• Tungsten carbide-coated rollers

• Special ceramic rollers

• Traction rollers

• Spreading rollers

• Fabric guide rollers

• Coating rollers

• Embossing rollers (as per customer-provided drawings)

• Tension control rollers

• High-precision solid rollers/hollow rollers

• Special coated composite rollers

For example, Jinhang Machinery's capabilities cover almost all of the above roller types and support various customizations.

What key details can a roller manufacturer process according to drawings?

A roller is not just a simple cylinder, but a precision mechanical part. A reputable roller manufacturer can process the following key aspects according to drawings:

1. Dimensions and Tolerances

Fully conforming to drawings:

• Outer diameter

• Shaft diameter

• Working surface length

• Overall length

• Keyway

• Mounting threads

• End face accuracy

• Runout tolerance

• Coaxiality requirements

These directly affect the operational stability of the equipment.

2. Materials and Substrate Design

Common materials:

• 45# steel

• Q345

• 304/316 stainless steel

• Alloy steel

• High-hardness tool steel

• Aluminum alloy

• Special anti-corrosion materials

Roller manufacturers will select materials based on drawings and can also substitute equivalent materials as required.

3. Surface Treatment Processes

Roll manufacturers can customize the following surfaces:

• Chrome plating

• Nickel plating

• Grinding, ultra-precision machining

• Mirror polishing

• Rubber coating

• Ceramic coating

• Tungsten carbide spraying

• Oxide layer

• Special insulating coating

Mirror rollers, tungsten carbide rollers, and corona-treated rollers are all manufactured strictly according to drawings.

4. Internal Structure Machining

Especially for heated and cooled rollers, manufacturers must achieve:

• Internal spiral flow channels

• Layered water channels

• Uniform temperature structure

• Precision welding and deformation-free processes

This requires extremely high manufacturing capabilities.

5. Dynamic Balance Grade

High-speed equipment typically requires:

• G2.5

• G1

• Even higher precision grades

Professional roller manufacturers adhere to drawing requirements.

What standards do roller manufacturers follow when customizing?

To ensure complete fidelity to drawings, professional roll manufacturers typically adhere to:

• ISO tolerance standards

• GB/T machining standards

• Coating thickness and structure standards

• Metal heat treatment standards

• Welding and pressure vessel standards (applicable to internal flow channels)

• Dynamic balancing ISO 1940/1 standard

Based on these systems, roll manufacturers can ensure that drawing requirements are consistently met.

How to determine if a roll manufacturer possesses reliable customization capabilities?

The following are the evaluation criteria:

1. Does the manufacturer possess large lathes, grinding machines, and specialized roller processing equipment?

2. Can the manufacturer process large-size rollers (e.g., over 8 meters)?

3. Does the manufacturer possess internal processes such as plating, spraying, and polishing?

4. Does the manufacturer possess independent dynamic balancing capabilities?

5. Can the manufacturer provide material reports and test reports?

6. Can the manufacturer support high-precision requirements (e.g., runout 0.002mm)?

7. Can the manufacturer fully read and analyze drawings?

8. Can the manufacturer conduct engineering assessments and technical confirmations based on drawings?

Professional roller manufacturers like Jinhang Machinery fully meet the above standards and are therefore capable of high-quality customization.

Why are roller manufacturers like Jinhang Machinery competent for high-precision customization?

Based on the information you provided, Jinhang Machinery, as a high-quality roller manufacturer in China, possesses the following core advantages:

• Custom processing based on customer drawings

• Engineering design optimization

• Manufacturing ultra-high precision roller bodies

• Processing various functional roller surfaces

• Producing multiple types of industrial rollers

• Meeting the structural requirements of various equipment

• Comprehensive processing technologies, including chrome plating, coating, spraying, grinding, and polishing

Therefore, they can not only process according to drawings but also ensure that the roller bodies meet high-standard industrial application requirements.

Can roller manufacturers customize processing based on drawings?

—Yes.

And not only can they, but they also include:

• Manufacturing strictly according to drawings

• Process review and technical optimization

• Completing high-precision processing

• Providing customized structures suitable for equipment

• Manufacturing various complex roller types

• Achieving special coatings and special functional processes

• Ensuring assembly compatibility and long service life

For equipment manufacturers, factory engineering departments, or purchasing personnel, as long as accurate drawings or technical parameters are provided, professional roller manufacturers can manufacture industrial rollers that fully meet the requirements.