What Does Jinhang Machinery Do? - Rollers Manufacturer

In industrial production, various rollers play a crucial role in processes such as coating, calendering, laminating, printing, calendering, cooling, and traction. Roller manufacturers capable of consistently producing high-precision rollers and meeting customized equipment requirements are vital support for the performance of industrial equipment.

Many people ask the same question when choosing a roller supplier: "What does Jinhang Machinery do?"

--- Jinhang Machinery is a high-quality industrial roller manufacturer from China, specializing in the research, development, processing, and customization of various industrial rollers. It can perform in-depth design and precision manufacturing based on customer drawings, operating conditions, and equipment parameters.

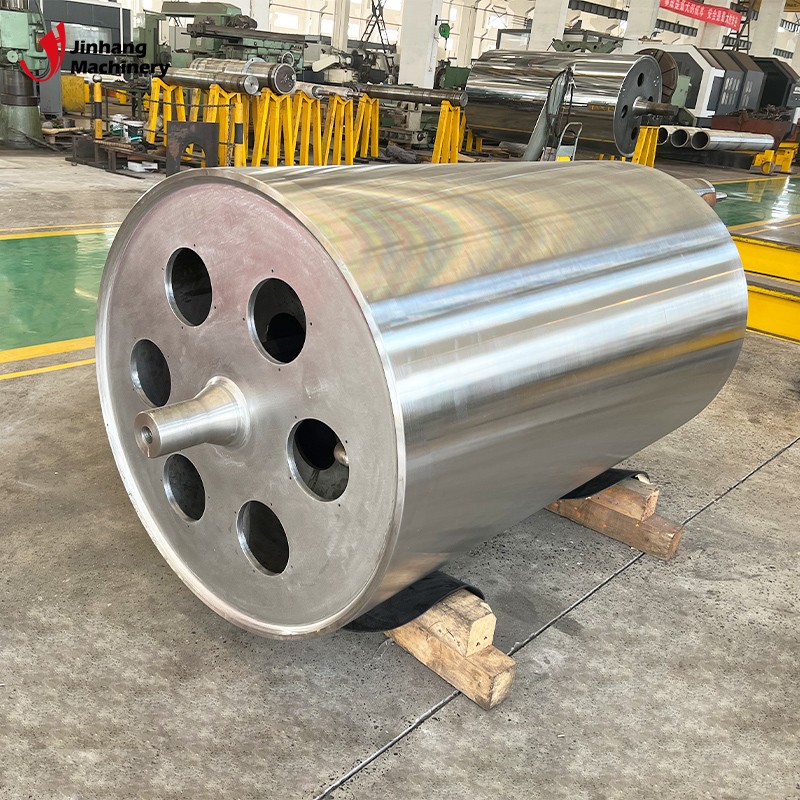

As a professional roller manufacturer, Jinhang Machinery's core business covers multiple areas including rubber rollers, metal rollers, functional rollers, and special roller coating processing, making it an indispensable supply chain force behind many industrial equipment projects.

What Are Jinhang Machinery's Main Business Areas?

As an experienced roller manufacturer, Jinhang Machinery's business extends beyond rubber rollers to encompass a complete production system for various high-precision rollers, including:

• Various industrial rubber rollers

• Heated rollers

• Mirror-finish rollers

• Cooling rollers

• Corona rollers

• Chrome-plated rollers

• Tungsten carbide rollers

• Various custom metal rollers and carbide-coated rollers

• Custom roller types with special structures and functions

More importantly, Jinhang Machinery can provide customized designs based on customer-provided drawings, dimensions, material requirements, or equipment operating conditions, ensuring that the manufactured rollers precisely match the production line's needs.

For any user seeking a reliable roller manufacturer, Jinhang Machinery's design, manufacturing, and processing capabilities are crucial for ensuring the stability of equipment operation.

What Are Jinhang Machinery's Advantages As a Roller Manufacturer?

A superior roller manufacturer typically possesses comprehensive capabilities across multiple areas, and Jinhang Machinery's strengths are primarily concentrated in the following aspects:

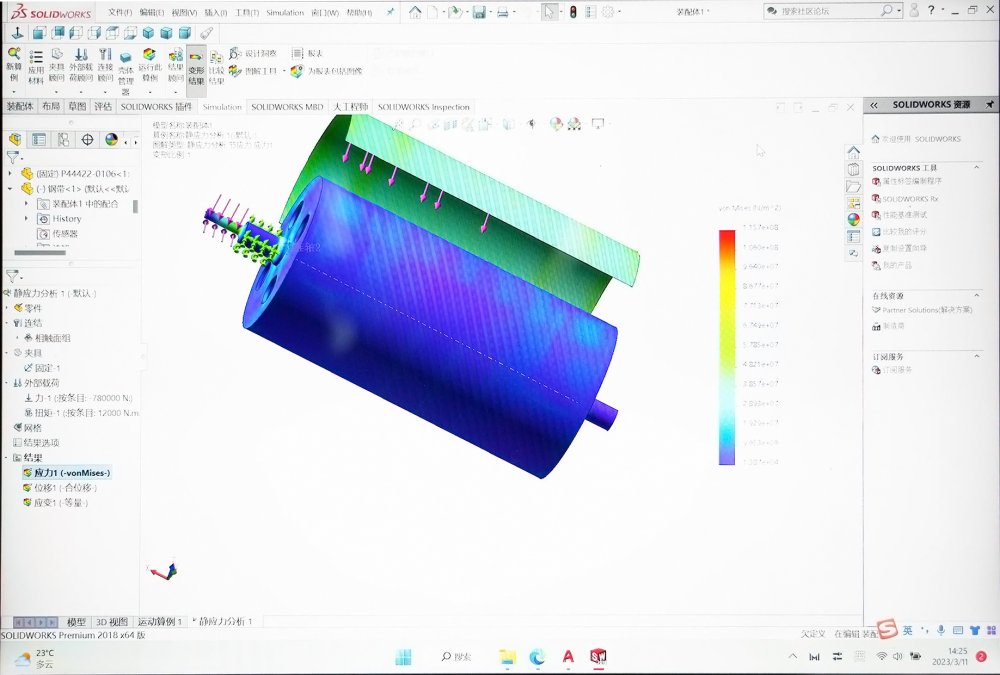

1. End-to-End Design and Manufacturing Capabilities

Jinhang Machinery is not merely a factory that "machines according to blueprints," but rather capable of:

• Designing roller structures based on equipment applications

• Selecting the optimal roller material based on material properties

• Determining suitable rubber layers, metal surfaces, or coatings based on operating conditions

• Evaluating roller performance based on conditions such as speed, pressure, and temperature

This holistic capability, from requirement to finished product, is difficult for many roller manufacturers to achieve.

2. Capability to Handle Various High-Difficulty Rollers and Coatings

Many production processes demand extremely high precision from rollers, such as:

• Mirror-finish rollers require extremely low surface roughness (Ra 0.01μm level)

• Heated rollers require a uniform internal cavity structure and constant temperature control

• Tungsten carbide coatings require high hardness and strong wear resistance

• Corona-treated rollers require a stable insulation layer

Jinhang Machinery's manufacturing capabilities are sufficient to handle these demanding rollers, demonstrating greater professionalism compared to typical roller manufacturers.

3. Roller Manufacturing Capabilities Applicable to Multiple Industries and Equipment

Their products are widely used in:

• Film Production Equipment

• Printing Presses

• Coating Machines

• Laminating Equipment

• Paper and Nonwoven Fabric Production Lines

• Metal Material Production (Aluminum Foil, Copper Foil, etc.)

• Packaging Material Processing Equipment

For entire production lines requiring various roller combinations, a roller manufacturer capable of providing multiple types of rollers undoubtedly offers greater stability and consistency.

4. High-Precision Testing and Quality Control Capabilities

Excellent roller manufacturers must possess a robust testing system, including:

• Circular Runout Testing

• Surface Roughness Testing

• Hardness Testing

• Dynamic Balance Testing

• Coating Thickness Testing

These capabilities ensure that every roller meets the equipment's operational requirements.

Why Do Various Industries Need Specialized Roller Manufacturers?

Whether it's rubber rollers, heated rollers, mirror rollers, or cooled rollers, rollers are indispensable whenever continuous processing, material conveying, or surface treatment is involved. The importance of professional roller manufacturers is mainly reflected in the following aspects:

1. Roller quality directly affects production efficiency

Any minor imperfections in the concentricity, hardness, or surface condition of the roller will be magnified during high-speed operation, affecting:

• Material flatness

• Pressure uniformity

• Coating thickness

• Printing quality

• Heat transfer efficiency

Using rollers of unstable quality in a machine will cause numerous production problems.

2. Roller lifespan affects production costs

Frequent roller replacements not only increase downtime but also raise equipment maintenance costs.

3. Special operating conditions require specialized manufacturing capabilities

For example:

• High-temperature environments require precise heating roller structures.

• High-wear conditions require tungsten carbide coated rollers.

• High-speed printing requires mirror-finish rollers with extremely high surface precision

• Coating lines require rubber rollers with suitable hardness and elasticity. Only professional roller manufacturers can produce rollers that meet these operating conditions.

What Types of Industrial Rubber Rollers Does Jinhang Machinery Provide?

Besides metal rollers, Jinhang Machinery is also a professional manufacturer of rubber rollers, including:

• NBR rubber rollers (high oil resistance)

• EPDM rubber rollers (high temperature and aging resistance)

• Silicone rollers (high temperature resistance, food grade)

• Polyurethane rubber rollers (high wear resistance)

• Neoprene rubber rollers (excellent overall performance)

Each type of rubber roller is suitable for different working conditions, and Jinhang Machinery can select the optimal rubber formula and hardness according to customer needs to ensure stable roller performance.

As a Roller Manufacturer, does Jinhang Machinery Support Customization?

1. Can it be customized based on drawings?

Yes. Jinhang Machinery explicitly states that it can manufacture according to CAD drawings or sketches provided by users.

2. Can it design rollers according to working conditions?

Also. Only the following information is needed:

• Temperature

• Pressure

• Material type

• Working speed

• Environmental conditions (such as solvents, oil, moisture, etc.)

A professional engineering team can design roller structures that meet the requirements.

3. Does it offer coating processing?

Yes, including:

• Tungsten carbide coating

• Chrome plating

• Special hardening coating

• Anti-corrosion coating

Therefore, whether customers require standard rollers or high-performance functional rollers, Jinhang Machinery, as a roller manufacturer, possesses comprehensive customization capabilities.

What Key Indicators Should be Considered When Choosing a Roller Manufacturer?

To help readers better assess the professionalism of a roller manufacturer, consider the following aspects:

1. Does it possess systematic processing equipment?

Including turning, grinding, dynamic balancing, and coating equipment.

2. Does it have testing equipment and records?

Good roller manufacturers will provide testing data.

3. Can it provide customized services?

Including design, material recommendations, and working condition assessment.

4. Does it have an experienced technical team?

The R&D capabilities of a roller manufacturer often determine product stability.

5. Can it produce multiple types of rollers?

The more diverse the production, the better it can provide a unified solution for the entire production line.

Jinhang Machinery possesses mature advantages in several key indicators mentioned above, making it a stable and reliable partner for industrial enterprises.

Why Do Many Companies Choose Jinhang Machinery As Their Roller Manufacturer?

In summary, the main reasons include:

• High-quality manufacturing capabilities

• Support for multiple fields and types of rollers

• Complete customized solutions

• Precise machining accuracy

• Rigorous testing system

• Stable delivery capabilities

For any company relying on roller equipment, choosing a reliable roller manufacturer is a crucial prerequisite for ensuring production quality, and Jinhang Machinery has earned widespread trust based on these capabilities.

What Kind of Roller Manufacturer is Jinhang Machinery?

Jinhang Machinery is a professional, comprehensive, and high-precision Chinese industrial roller manufacturer. Its services cover rubber rollers, metal rollers, functional rollers, and various special coated rollers, providing customized manufacturing solutions based on customer working conditions or drawings.

If you are looking for a stable and reliable roller manufacturer, Jinhang Machinery is undoubtedly a trustworthy choice.