Can Jinhang Machinery Customize Industrial Rollers?

In modern industrial production, high-precision, high-durability industrial rollers that are highly compatible with production line requirements play a crucial role in the performance and process quality of equipment across various industries. Therefore, when choosing an industrial roller supplier, companies not only care about the type of products offered but also whether the supplier has customization capabilities.

Many customers ask a core question about this:

"Can Jinhang Machinery customize industrial rollers?"

The answer is very clear—yes, and very professionally.

As one of China's leading high-quality industrial roller manufacturers, Jinhang Machinery possesses mature capabilities in designing and manufacturing various high-precision rollers. We can tailor rollers with various structures, sizes, and special functions to meet specific customer needs. Therefore, whether in the printing, paper, film, coating, lithium battery, metal processing, or plastics processing industries, Jinhang Machinery can provide professional solutions that fully meet production requirements.

This article will comprehensively explain our customization capabilities, manufacturing processes, types of rollers that can be processed, and the advantages of collaborating with roller manufacturers.

Why do customers ask, "Does Jinhang Machinery have the capability to customize industrial rollers?"

Many companies ask this question because industrial rollers are highly dependent on equipment and must possess the following characteristics:

• Perfect structural dimensions matching the equipment

• Materials meeting specific operating conditions

• Precision meeting equipment operating standards

• Surface characteristics requiring specialized treatment based on the processed object

• Reliable service life and performance

• Some equipment has extremely high requirements for roller surface roughness, runout, and even coating characteristics.

Therefore, only roller manufacturers with a complete production chain and a professional technical team can truly achieve "customization."

Jinhang Machinery is precisely such a roller manufacturer.

What are Jinhang Machinery's core advantages as a roller manufacturer?

An excellent roller manufacturer needs capabilities across the entire process, including design, processing, manufacturing, testing, and assembly.

Jinhang Machinery, as a professional roller manufacturer, possesses the following significant advantages:

1. Comprehensive Industrial Roller Customization Capabilities

Jinhang Machinery can customize designs based on customers':

• Equipment design drawings

• Roller operating environment

• Load range

• Temperature requirements

• Surface performance requirements

• Operating speed

• Coating or rubber type

This personalized design is crucial.

In industrial production, few roller manufacturers can truly achieve "deep customization based on drawings," but Jinhang Machinery possesses this capability.

2. Extensive Roller Machining Experience

As an experienced roller manufacturer, Jinhang Machinery can process a large variety of different types of rollers and precisely control every key parameter, such as:

• Roundness

• Runout

• Coaxiality

• Roughness

• Hardness

• Surface energy

• Structural stability

This level of expertise is a key criterion for judging whether a roller manufacturer has customization capabilities.

3. Comprehensive Surface Treatment Capabilities

Jinhang Machinery offers a wide range of professional surface treatments, including:

• Chrome plating

• Tungsten carbide spraying

• Mirror polishing

• Special functional coatings

• High-precision surface grinding

• Industrial rubber coating

These capabilities are crucial because the surface properties of different industrial rollers directly impact production quality.

4. Capability to Process Various High-Demand Roll Types

Including but not limited to:

• Rubber rollers

• Chrome-plated rollers

• Tungsten carbide rollers

• Cooling rollers

• Heating rollers

• Mirror-finish rollers

• Corona-treated rollers

• Special functional rollers

• Ultra-high precision roller bodies

The wider the range of rollers that can be processed, the stronger the roller manufacturer's expertise.

Jinhang Machinery can fully meet all these needs.

What types of industrial rollers can Jinhang Machinery customize?

As a professional roller manufacturer, Jinhang Machinery offers a comprehensive range of classifications, covering various industrial equipment.

1. Rubber Rollers

Includes:

• NBR rubber rollers

• EPDM rubber rollers

• Silicone rollers

• Polyurethane rollers

• Acid and alkali resistant rollers

• High temperature resistant rollers

Suitable for printing, packaging, lithium battery, woodworking, textile, and other industries.

2. Chrome-plated Rollers

Used in applications requiring high wear resistance and high surface finish, such as hot pressing and film processing.

3. Mirror Rollers

Mirror rollers are essential for processing applications requiring high flatness and high surface finish, such as film calendering and brightening.

4. Heated/Cooled Rollers

Internally circulated with oil or water, used to control processing temperature; a key functional roller in many production lines.

5. Tungsten Carbide Rollers

High hardness and strong wear resistance, suitable for high-intensity applications such as metal processing, etching, and tension control.

6. Corona Rollers

Used for film surface treatment, giving materials higher surface adhesion; widely used in the plastic film industry.

7. Special Roll Types and Custom Rolls

Examples:

• Anilox Rolls

• Patterned Rolls

• Guide Rolls

• Coating Rolls

• Tension Rolls

Jinhang Machinery can fully customize rollers according to customer needs.

Why Choose a Professional Roll Manufacturer for Custom Industrial Rolls?

The difference between choosing a general manufacturer and a professional roller manufacturer can be enormous. Industrial rollers are high-precision industrial components that directly impact production quality; therefore, choosing a professional manufacturer is essential.

Here are the key reasons for choosing a professional roller manufacturer:

1. Ensuring Precise Matching of Rolls to Equipment

Only professional roller manufacturers can ensure:

• Precise Dimensions

• Minimal Coaxiality Deviation

• Stable Operation

• Perfect Fit to Equipment Structure

This determines the efficiency and stability of the production line.

2. More Professional Material Selection

Roll manufacturers select the most suitable materials based on the customer's operating conditions, such as:

• Heated rollers for high-temperature environments

• EPDM or corrosion-resistant materials for chemical environments

• Tungsten carbide rollers for high-wear environments

• Mirror-finish rollers for high-gloss requirements

3. Surface Treatment Determines Service Life

Professional roller manufacturers possess key surface treatment capabilities, which are crucial to roller life and performance.

4. Precision Determines Processing Quality

Industrial rollers are high-precision components; only professional manufacturers can achieve the high precision requirements, ensuring stable production results.

What is Jinhang Machinery's industrial roller customization process?

As a professional roller manufacturer, Jinhang Machinery employs a systematic and rigorous customization process, generally including:

1. Customer Requirements Confirmation

Examples:

• Roller dimensions

• Material requirements

• Operating temperature

• Surface roughness

• Application scenario

• Outer coating process

2. Drawing Design or Receiving Customer Drawings

Possible options:

• Complete customization based on customer drawings

• Or redesign by the engineering team

3. Material Selection

Selecting suitable steel, rubber, or coating materials based on operating conditions.

4. Rough Machining → Finish Machining → Grinding → Surface Treatment

Strict process control.

5. Inspection and Quality Control

Including:

• Dynamic balancing test

• Surface hardness test

• Coaxiality measurement

• Roundness and runout test

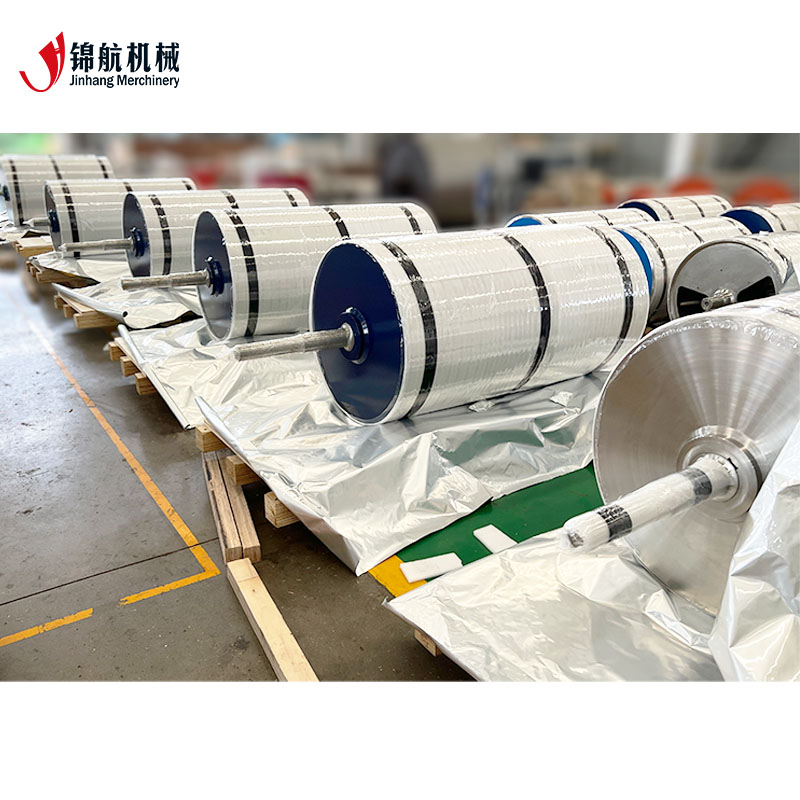

6. Packaging and Transportation

Ensuring the roller is not damaged during transportation.

What are the benefits of partnering with Jinhang Machinery?

As a mature roller manufacturer, the company offers:

• Highly flexible customization capabilities

• Stable machining precision

• Multiple professional surface treatments

• Rapid response to needs

• High-quality materials and strict quality control

• Production of industrial rollers with various complex structures

This makes it an ideal partner for companies seeking a long-term, stable supplier.

Can Jinhang Machinery customize industrial rollers?

—Yes, and with great expertise.

✔ Jinhang Machinery is a truly professional roller manufacturer

✔ Can fully customize rollers according to customer drawings or requirements

✔ Can process various types and high-precision industrial rollers

✔ Possesses complete design, manufacturing, and testing capabilities

✔ Can meet the stringent requirements of multiple industries for roller bodies

Therefore, if a company needs a reliable roller manufacturer to customize industrial rollers, Jinhang Machinery is an excellent, professional, and stable choice.