Can Roller Manufacturers Customize According To My Drawings?

In industrial production, rollers are irreplaceable core components in many mechanical systems, including printing, coating, plastic extrusion, metal rolling, composite material manufacturing, and electronic material processing.

Many companies face a crucial question when designing equipment or upgrading production lines: Can roller manufacturers customize according to my drawings?

The answer is yes, and professional roller manufacturers can not only manufacture according to drawings but also provide engineering-level design and optimization based on your equipment requirements.

As a high-quality industrial roller supplier in China, Jinhang Machinery is such a roller manufacturer that can provide customized drawings and structural designs. From material selection, strength verification, surface treatment to final machining accuracy, we can provide you with high-standard industrial rollers ready for direct production, tailored to your needs.

This article will delve into: Why can roller manufacturers customize according to drawings? What steps are involved in customizing rollers? Are user-provided drawings sufficient? What engineering problems can roller manufacturers solve for businesses?

Why can roller manufacturers customize according to customer drawings?

Many companies ask, "Can roller manufacturers really manufacture exactly according to my drawings?"

The answer is yes, because professional roller manufacturers possess three core qualities:

1. A complete industrial roller manufacturing chain

Professional roller manufacturers possess:

• Large lathes, grinding machines, and dynamic balancing equipment

• Chrome plating, electroplating, spraying, and thermal spraying lines

• Mirror polishing systems

• Internal water channel and oil channel processing equipment

This equipment is specifically designed for manufacturing industrial rollers, so roller manufacturers can manufacture to specifications, regardless of the drawings with clearly defined dimensions and process requirements.

2. Familiarity with the structural characteristics of various roller types

Roller manufacturers process year-round:

• Rubber rollers

• Chrome-plated rollers

• Mirror-finish rollers

• Heated rollers

• Cooled rollers

• Corona-treated rollers

• Tungsten carbide rollers

• Specially coated rollers

Therefore, regardless of the drawing structure, roller manufacturers can identify critical dimensions, structural safety, and environmental requirements, thus ensuring manufacturing quality.

3. Possessing engineering capabilities, capable of drawing verification and structural validation

A truly professional roller manufacturer is not just a "processing plant," but an "engineering service provider."

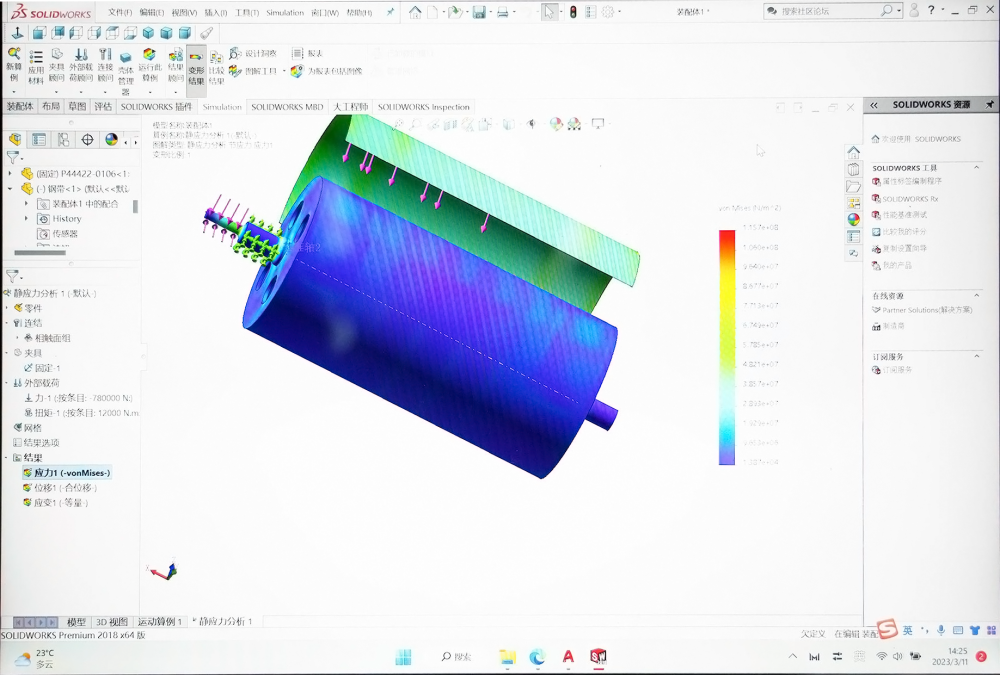

For example, Jinhang Machinery's engineering team will perform strength checks and manufacturability verifications based on the drawings to ensure the rollers operate stably in your production environment.

What engineering analyses does a roller manufacturer perform after receiving drawings?

After you provide the drawings, the roller manufacturer will not directly manufacture them, but will conduct a comprehensive engineering assessment.

1. Does the material selection meet the load requirements?

Roller materials may include:

• 45# steel

• 40Cr

• Stainless steel 304/316

• Alloy steel

• Tungsten carbide coated substrate

• High-hardness chrome-plated substrate

The roller manufacturer will determine whether material optimization is needed based on:

• Weight

• Torque

• Operating temperature

• Pressure

• Linear speed

2. Is the roller structure resistant to bending and fatigue?

Engineers will conduct mechanical analysis, including:

• Is the wall thickness sufficient?

• Is the shaft diameter reasonable?

• Are stress concentration areas safe?

• Does the internal structure cause insufficient strength?

This step ensures the roller will not deform under high temperature, high pressure, high speed, or other operating conditions.

3. Does the internal flow channel design meet thermal balance?

For heated rollers, cooled rollers, mirror rollers, and calendering rollers, the internal flow channel structure is particularly critical.

Roller manufacturers will evaluate:

• Flow channel diameter

• Helix angle

• Flow distribution

• Inlet/outlet location

To ensure uniform mirror surface temperature.

4. Does the surface treatment meet actual requirements?

For example:

• Chrome plating thickness

• Tungsten carbide coating hardness

• Rubber overlay material

• Mirror surface roughness grade

• Type of insulating coating for corona rollers

Roller manufacturers will confirm your process requirements, such as whether corrosion resistance, wear resistance, high temperature resistance, thermal conductivity, or insulation properties are needed.

Can the roller manufacturer optimize customer drawings to make the structure more reasonable?

Many companies would answer: Yes, and it's absolutely necessary.

While you can provide drawings, the complex environment of the equipment, with varying temperatures, speeds, and materials requiring different roller structures, necessitates specialized roller manufacturers. Therefore, professional roller manufacturers will:

1. Redesign the roller structure according to equipment requirements

For example:

• Adjust wall thickness

• Strengthen journal structure

• Improve flow channel design

• Optimize end cap welding methods

• Add strength treatment

This improves the roller's lifespan and stability.

2. Confirm the appropriateness of machining precision

Roll manufacturers will recommend:

• Surface runout range

• Coaxiality requirements

• Roughness grade

• Balance grade (e.g., G1/G2.5)

These directly affect the roller's operating quality.

3. Optimize surface treatment to better suit process requirements

For example:

• Use a special ceramic coating instead of ordinary chrome plating

• Use tungsten carbide to ensure wear resistance

• Select suitable rubber materials for corona rollers

• Adjust the polishing level of mirror rollers

Professional roller manufacturers' engineering departments will provide precise advice, rather than mechanically following instructions.

What information must be provided for custom rollers?

Even if roller manufacturers can process according to drawings, the more complete the information provided by the customer, the more precise the finished product will be.

Required information includes:

1. Complete drawings or basic dimensions

e.g.,

• Roller diameter

• Total length

• Shaft diameter and mounting method

• Surface treatment requirements

• Substrate type

2. Operating environment

Including:

• Maximum temperature

• Minimum temperature

• Linear speed

• Pressure

• Loading method (eccentric, concentrated, uniform)

3. Surface performance requirements

e.g.,

• Film mirror finish grade (Ra 0.01–0.05μm)

• Roughness for coating rollers

• Insulation performance requirements for corona rollers

• Abrasion and corrosion resistance grades

4. Is a professional engineer required to redesign the drawings?

If your equipment requires further structural optimization, the roller manufacturer can design new machining drawings for you.

What types of industrial rollers can the roller manufacturer customize?

In the industrial roller industry, professional roller manufacturers offer a wide range of customization options, including but not limited to:

• Industrial rubber rollers

• Chrome-plated rollers

• Mirror-finish rollers

• Cooling rollers

• Heating rollers

• Corona rollers

• Tungsten carbide coated rollers

• Ceramic rollers

• Special coating rollers

• High-strength steel rollers

• Anilox rollers

• Composite material rollers

Jinhang Machinery can process rollers according to customer drawings and also provides a one-stop service from design to finished product, including:

• Material selection

• Internal structure design

• Surface treatment

• Precision assurance

• Dynamic balancing

• Assembly and testing

This is the value of a professional roller manufacturer.

How do roller manufacturers ensure the machining precision of customized rollers?

High-precision industrial rollers cannot be manufactured by ordinary machine shops. Roller manufacturers possess the following capabilities:

1. High-precision CNC turning and grinding systems

Ensuring the roller body achieves:

• Roundness

• Coaxiality

• Straightness

• Surface flatness

Meets high industry standards.

2. Dynamic balancing testing equipment

Ensuring the roller operates at high speeds:

• No vibration

• No shock

• No bearing damage

3. High-standard chrome plating, spraying, ceramic, or tungsten carbide processes

Ensuring:

• Surface hardness

• Wear resistance

• Corrosion resistance

• Adhesion

4. Mirror polishing system

Meets the requirements for optical-grade mirror rollers.

5. Engineer-led end-to-end monitoring

Professional roller manufacturers develop machining routes based on every detail in the drawings, ensuring zero errors.

Why is choosing a professional roller manufacturer more reliable than a general machine shop?

While general machinery factories can perform machining operations, they lack the expertise in designing industrial roller structures. Roller manufacturers, on the other hand, possess:

• In-depth understanding of the fatigue characteristics of various roller materials

• Familiarity with roller performance in high-temperature, high-speed, and humid environments

• Ability to perform thermodynamic analysis for flow channel design

• Ability to guarantee high-standard surface treatment

• Familiarity with the process requirements of various industries

Therefore, choosing a professional roller manufacturer not only ensures machining but also guarantees the roller's proper operation under actual working conditions, preventing breakage, deformation, imbalance, or surface peeling.

What are the advantages of customizing drawings through a roller manufacturer?

1. Adaptability to any non-standard equipment

Equipment manufacturers typically only provide basic interface information, while roller manufacturers can redesign the roller structure according to equipment requirements.

2. Significantly reduced roller usage risks

Improper roller material selection and structural design can lead to:

• Breakage

• Deformation

• Surface peeling

• Uneven temperature

• Shortened service life

Roller manufacturers' engineering capabilities can prevent these problems.

3. Higher Surface Finish Quality

Ordinary processing plants struggle to achieve complex processes like mirror-finish rollers and tungsten carbide rollers, while professional roller manufacturers can meet industry-standard requirements.

4. More Stable Production Line Operation

Higher precision leads to higher production efficiency and lower scrap rates.

Roll Manufacturers Can Customize Rollers According To Drawings and Provide Engineering-Level Design Support

More importantly, professional roller manufacturers not only manufacture according to drawings but also provide structural optimization, material recommendations, strength analysis, thermodynamic analysis, processing route planning, and final product testing.

Jinhang Machinery, as a high-quality industrial roller manufacturer in China, offers you:

• Drawing Processing

• Professional Design

• Engineering Verification

• Custom Materials

• Custom Surface Finishes

• High-Precision Machining

• Safe and Reliable Structural Design

Therefore, as long as you provide your equipment requirements or basic drawings, the roller manufacturer can complete a full customization process for you, covering everything from design to manufacturing.