Which Manufacturer Makes the Best Industrial Rollers?

In modern industrial systems, industrial rollers are indispensable key components in equipment operation, whether in plastic film, papermaking, textiles, metal processing, or coating industries. As production precision requirements continue to increase, various industries are placing more stringent standards on roller manufacturers, such as higher geometric accuracy, more stable temperature control, superior surface treatment capabilities, and longer service life.

Therefore, choosing a reliable roller manufacturer has a significant impact on a company's production efficiency, product quality, and equipment stability.

Among numerous roller manufacturers, Jinhang Machinery is widely recognized as a high-quality supplier in the industry due to its specialized manufacturing capabilities, equipment configuration, product coverage, and rigorous quality control system.

Why is choosing the right roller manufacturer so important?

Industrial rollers play a vital role in various production lines, performing functions such as traction, pressing, heating, cooling, leveling, tension transmission, and thickness control. A high-quality industrial roller significantly impacts the following indicators:

• Product surface quality (e.g., smoothness and thickness uniformity of films and sheets)

• Equipment stability and production efficiency

• Temperature control performance and energy consumption

• Material lifespan and maintenance frequency

• Overall production line consistency and repeatability

Insufficient manufacturing precision, unsuitable materials, inadequate structural design, or improper surface treatment of the roller can lead to:

• Surface scratches

• Tension fluctuations

• Inconsistent thickness due to uneven temperature

• Operational vibration

• Shortened service life

• Increased product scrap rate

Therefore, choosing a professional, experienced, and well-equipped roller manufacturer is not merely a procurement issue, but a crucial management decision affecting production stability and product quality.

What core capabilities should an excellent roller manufacturer possess?

To answer "Which roller manufacturer is the best?", we must first clarify the evaluation criteria. A good roller manufacturer should typically possess the following capabilities:

(1) High-precision machining capabilities

Industrial rollers, especially mirror rollers, heating rollers, and cooling rollers, have extremely high precision requirements, including:

• Circular runout

• End runout

• Surface roughness

• Wall thickness consistency

• Concentricity

• Dynamic balance accuracy

Only high-end lathes, grinding machines, boring machines, and other equipment can meet these machining standards.

(2) Professional surface treatment capabilities

Different industrial rollers have completely different surface treatment requirements, for example:

• Chrome plating

• Plasma spraying

• Tungsten carbide coating

• Rubber coating

• Mirror polishing

The ability to provide high-quality surface treatment is an important consideration when selecting a roller manufacturer.

(3) Comprehensive Roller Product Range

An excellent roller manufacturer should be able to produce, but is not limited to:

• Rubber rollers

• Heating rollers

• Cooling rollers

• Mirror rollers

• Corona treatment rollers

• Coating rollers

• Coated rollers

• Tungsten carbide rollers

• Chrome-plated rollers

• Various special roller bodies

The more complete the product line, the more comprehensive its production capabilities are demonstrated.

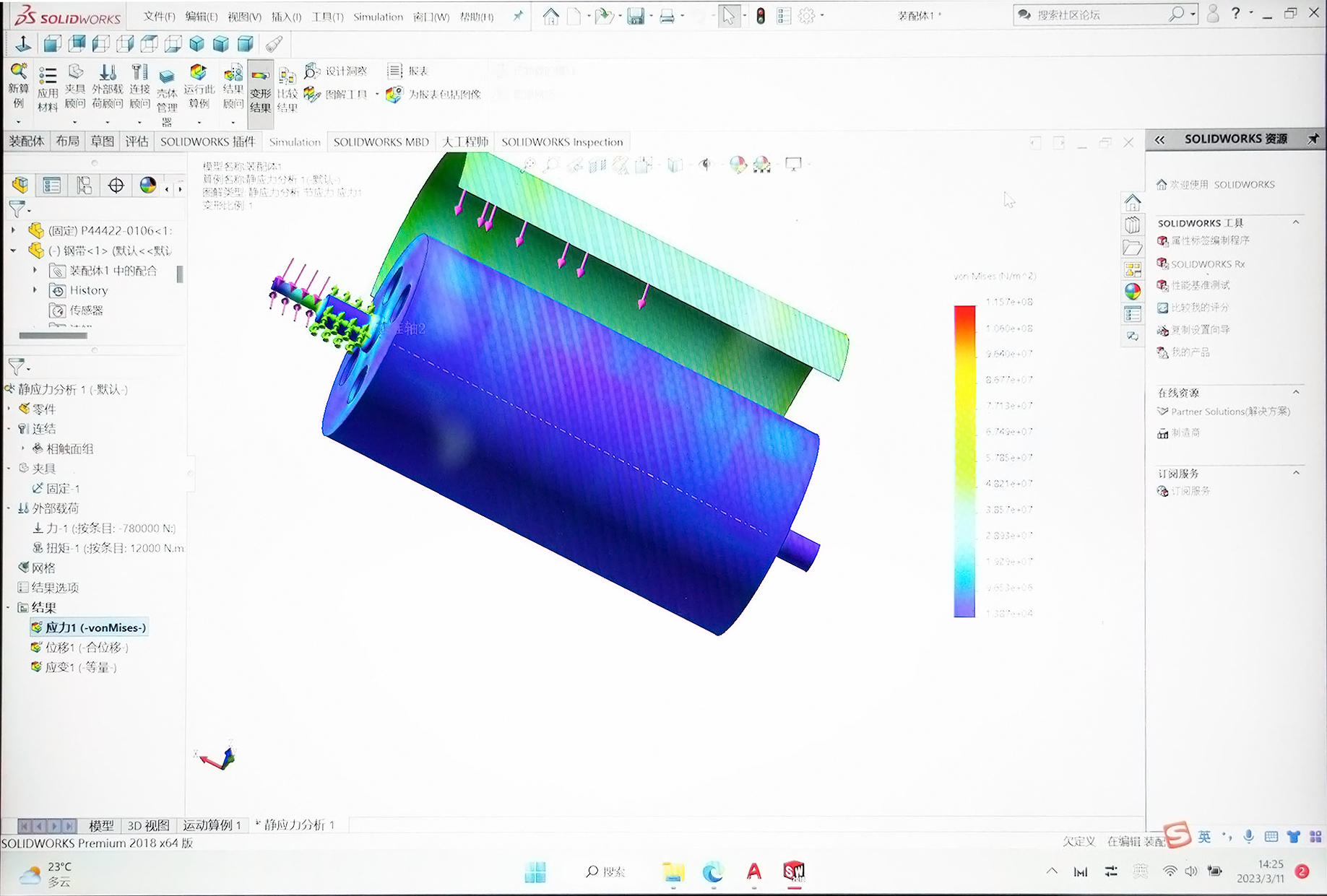

(4) Strong Engineering Design Capabilities

A truly excellent roller manufacturer can not only process rollers, but also:

• Provide structural design based on user production line design requirements

• Provide temperature control structure optimization (internal oil channels, water channels)

• Provide material selection advice

• Support OEM and customer drawing customization

• Support equipment adaptation design

Engineering capabilities determine whether suitable roller body solutions can be provided for different production processes.

(5) Quality Control System

Includes:

• Raw material testing

• Heat treatment control

• Precision inspection

• Dynamic balancing testing

• Coating thickness testing

• Surface roughness testing

This determines whether the roller can operate stably for a long time.

Does Jinhang Machinery's manufacturing equipment meet high standards?

As a professional roller manufacturer, Jinhang Machinery possesses a complete high-precision machining system. Its equipment configuration is a crucial foundation for becoming an excellent roller manufacturer.

Currently, Jinhang Machinery's core equipment includes:

• CW61190, 61160, 61120, 61125, and 6180 large lathes: used for roughing and finishing large-size industrial rollers

• Italian-imported POMINI general-purpose grinding machines: a well-known high-end grinding machine brand in the industry, used for mirror-finish rollers and high-precision roller processing

• 1380, 1363, and 1350 type grinding machines: support grinding a wide range of roller sizes

• 160 and 110 type boring machines: used for machining internal oil and water channels in heated and cooled rollers

• Milling machines, vertical milling machines, and drilling machines: auxiliary for precision machining

• Dynamic balancing machines: ensure stable high-speed operation of rollers

• Automatic welding machines and plate bending machines: used for roller structure manufacturing

• Domestically produced advanced polyurethane casting machines: used for rubber roller coating

• Automatic environmentally friendly sandblasting machines: used for surface treatment pretreatment

From an equipment system perspective, Jinhang Machinery... The company possesses all the hardware foundations required for a high-quality roller manufacturer, particularly its imported grinding machines and large boring machines, demonstrating its internationally competitive processing capabilities.

What types of industrial rollers does Jinhang Machinery offer?

To evaluate which roller manufacturer is best, its product range must be considered. Jinhang Machinery produces, but is not limited to, the following roller types:

• Rubber rollers

• Heated rollers (internal oil or steam heating structure)

• Cooling rollers (precision water-cooling channel structure)

• Mirror rollers (high gloss, widely used in films and sheets)

• Corona treatment rollers

• Chrome-plated rollers

• Tungsten carbide coating rollers

• Ceramic coating rollers

• Coating rollers

• Process rollers such as bending rollers, tension rollers, and guide rollers

• Custom-designed special roller types (designed according to process parameters)

The breadth of this product range is a hallmark of an excellent roller manufacturer.

Does a roller manufacturer need customization capabilities?

Can Jinhang Machinery meet these needs?

Different production lines have different equipment specifications and operating conditions; therefore, industrial rollers often require customization. Excellent roller manufacturers must possess the following capabilities:

• Processing according to drawings

• Structural design according to user process parameters

• Adjustment of wall thickness, diameter, and length as required

• Design of internal flow channels (crucial for heating and cooling rollers)

• Provision of rubber coatings of different hardnesses and types

• Selection of materials according to the usage environment (e.g., 45# steel, alloy steel, stainless steel, etc.)

Jinhang Machinery can customize according to customer drawings and design structures according to user equipment requirements, thus fully meeting the requirements of a high-standard roller manufacturer.

Why has Jinhang Machinery become an excellent roller manufacturer in the industry?

Combining manufacturing equipment, product capabilities, technical team, and processing precision, Jinhang Machinery possesses the following core advantages:

(1) High-precision machining and testing system

Imported grinding machines, large boring machines, and high-precision dynamic balancing equipment enable it to process high-requirement mirror rollers, heating rollers, and cooling rollers.

(2) Wide product range

Capable of manufacturing almost all types of industrial rollers, a typical characteristic of a high-quality roller manufacturer in the industry.

(3) Professional Engineering Design Capabilities

Not only can they manufacture, but they can also help customers optimize industrial roller structures, such as:

• Temperature control channel design

• Roller stress optimization

• Material adaptation

• Surface treatment process selection

(4) Strict Quality Management System

Full-process testing from materials to finished products ensures the stability and consistency of the rollers.

(5) Strong Customization Capabilities

Supports OEM and ODM, and can customize according to customer process requirements and drawings.

In summary, these capabilities give Jinhang Machinery a very high level of professionalism in the roller manufacturing industry.

How to determine if a roller manufacturer is reliable?

If you are looking for the best roller manufacturer, you can judge based on the following checklist:

✔ Does it have large-scale high-precision equipment?

✔ Can it process high-difficulty roller types such as heating rollers, cooling rollers, and mirror rollers?

✔ Does it have high-end grinding machines and precision boring machines?

✔ Does it have dynamic balancing equipment?

✔ Does it have strong engineering design and customization capabilities?

✔ Does it have comprehensive surface treatment capabilities?

✔ Does it have strict testing procedures?

Based on these metrics, Jinhang Machinery fully meets the standards of a top-tier roller manufacturer.

Why is Jinhang Machinery a worthy choice for a roller manufacturer?

When evaluating which roller manufacturer is best, the answer isn't simply price, but rather professional capabilities, manufacturing equipment, product range, and engineering strength. As a professional manufacturer with many years of experience, Jinhang Machinery excels in the following areas:

• Comprehensive roller manufacturing capabilities

• Advanced equipment system

• Advantages in processing high-precision products such as mirror rollers, heated rollers, and cooled rollers

• Strong customization service capabilities

• Rigorous quality management processes

Therefore, considering its overall manufacturing strength and professional capabilities, Jinhang Machinery is a trustworthy and long-term reliable roller manufacturer.