How long can the chrome plating of industrial chrome plated rollers last?

Chrome plated rollers play a vital role in industrial production. Its core function is to improve the wear resistance, corrosion resistance and surface finish of the rollers through the chrome plating on the surface, thereby extending the service life of the equipment and improving production efficiency. For many industries that use chrome plated rollers, the service life of the chrome plating is one of the key factors that determine its economy and efficiency. So, how long can the chrome plating of industrial chrome plated rollers last?

This article will help readers better understand and anticipate the service life of chrome plated rollers by deeply discussing the characteristics of the chrome plating, the factors that affect its life, and its performance in practical applications.

What is a chrome plated roller?

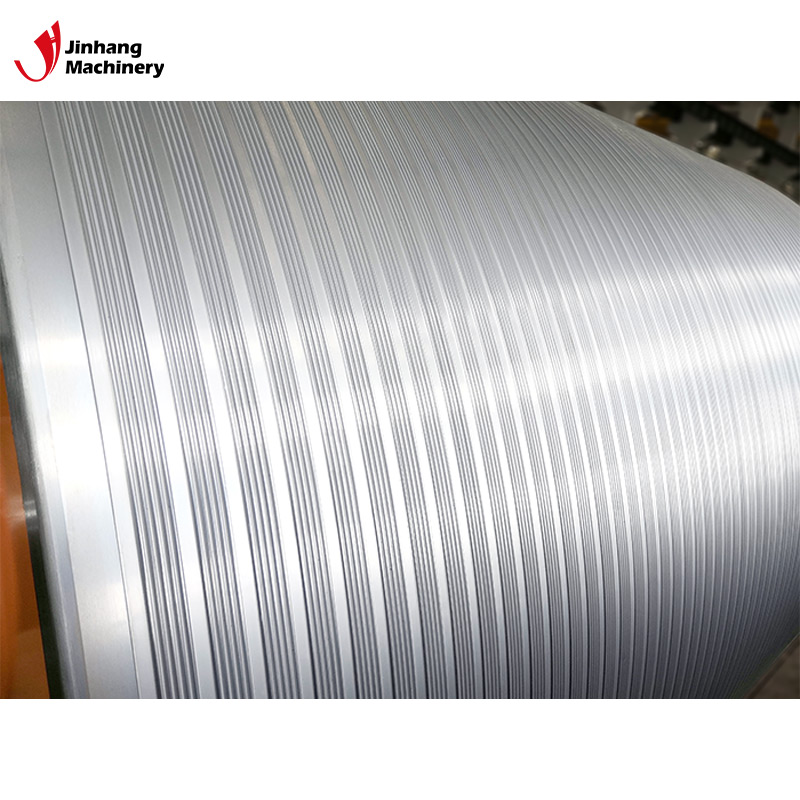

Chrome plated rollers refer to industrial equipment that is covered with a layer of chrome metal film on the surface of the roller through an electroplating process. Chromium is a silvery-white metal with very high hardness and corrosion resistance, making it an ideal material for enhancing roller performance. The main functions of chrome plating include:

● Improve wear resistance: The high hardness of the chrome layer of the chrome plated roller significantly enhances the wear resistance of the roller and reduces the wear caused by friction.

● Enhance corrosion resistance: The chemical inertness of the chrome layer enables it to resist the erosion of most acid and alkali substances, protecting the roller from working for a long time in a corrosive environment.

● Improve surface finish: The smooth chrome layer surface helps to reduce the friction between the chrome plated roller and the processed material and improve product quality.

What is the standard thickness of the chrome plating?

Before discussing the service life of the chrome plating, it is necessary to understand its standard thickness. The thickness of the industrial chrome plating layer is usually between 20 and 100 microns, and the specific thickness depends on the purpose and working environment of the chrome plated roller. The greater the thickness, the stronger the wear resistance and corrosion resistance of the chrome plating layer, but it also increases the cost.

● Thin layer chrome plating (20-30 microns): suitable for rollers with low load or short-term use.

● Medium-thick layer chrome plating (30-60 microns): widely used in ordinary industrial environments, suitable for medium load and wear conditions.

● Thick chrome plating (60-100 microns): For rollers under high load, high wear or extreme environmental conditions, the service life is relatively long.

What are the factors that affect the service life of the chrome plating?

The service life of the chrome plating is not fixed, but is affected by multiple factors. These factors include but are not limited to:

Working environment

The working environment of the chrome plated roller has a direct impact on the life of its chrome plating. Exposure to corrosive chemicals, high temperature or extreme humidity will accelerate the aging and corrosion of the chrome plating.

● Corrosive environment: Although the chrome plating has good corrosion resistance, it may still suffer corrosion damage when it is exposed to strong acids, strong alkalis or other corrosive chemicals for a long time. Especially in industries such as chemicals and pharmaceuticals, the working environment is highly corrosive and the service life of the chrome plating may be greatly shortened.

● High temperature environment: Continuous high temperature will cause thermal oxidation of the chrome plating and accelerate its surface degradation. In high temperature industries such as metallurgy or glass manufacturing, the service life of the chrome plating is usually short.

● High humidity environment: In a high humidity environment, chrome plated rollers are easily affected by water vapor, causing surface rust and reducing their durability.

Load and wear

The load of chrome plated rollers and the wear generated during operation are also important factors affecting the life of the chrome plating. High load and frequent friction will cause the chrome plating to wear more and shorten its service life.

● Mechanical wear: The contact between chrome plated rollers and materials during operation will cause mechanical wear, especially when processing hard materials. If the chrome plating is thin, the wear rate will be significantly accelerated.

● Impact load: When processing heavy or high-strength materials, the rollers may be subjected to greater impact forces, which will cause local peeling or cracking of the chrome plating, thereby reducing its life.

Maintenance and care

Good maintenance and care can significantly extend the service life of the chrome plating. Regularly cleaning the roller surface, avoiding the accumulation of corrosive substances, and promptly repairing surface damage are all key to maintaining the durability of the chrome plating.

● Regular cleaning: Regularly remove dirt and residues from the surface of chrome plated rollers to avoid potential damage to the chrome plating caused by these impurities.

● Surface repair: When minor cracks or wear are found on the chrome plated layer, timely repair treatment can prevent the damage from expanding, thereby extending its service life.

● Reasonable use: Avoiding overload of chrome plated rollers and ensuring that they work within their designed load range is the basic guarantee for extending the life of the chrome plated layer.

Frequency of use

The frequency of use of chrome plated rollers is also an important factor affecting the life of the chrome plated layer. Frequently used rollers will naturally wear the chrome plated layer much faster than intermittently used rollers.

● High frequency use: In continuous production lines, chrome plated rollers operate almost around the clock, which will accelerate the wear of the chrome plated layer and shorten its life.

● Low frequency use: In intermittent production, the service life of chrome plated rollers is relatively long because they wear more slowly.

What is the service life of industrial chrome plated rollers?

Although there are many factors that affect the life of the chrome plated layer, the service life of chrome plated rollers can be roughly estimated through statistical analysis of actual usage. Generally speaking, the chrome plating of industrial chrome plated rollers can last from several months to several years under normal working conditions.

● Light load, low wear environment: In an environment with relatively mild use conditions, the service life of the chrome plating is usually 1 to 3 years. Chrome plated rollers in such environments are usually used to handle softer materials, the working environment is relatively stable, and wear and corrosion are less.

● Medium load, conventional wear environment: In an environment with medium load and wear, such as paper processing, textile printing and dyeing, the life of the chrome plating is about 6 months to 1 year. Rollers in such environments need to cope with more frequent use and moderate wear.

● Heavy load, high wear environment: In an environment with high load and severe wear, such as metallurgy, glass manufacturing and other industries, the life of the chrome plating is usually only a few months. Chrome plated rollers in such environments need to frequently replace the chrome plating to maintain their functions and performance.

How to extend the service life of the chrome plating?

In order to maximize the service life of the chrome plated roller, companies can effectively extend its life by selecting a chrome plating of appropriate thickness according to the actual use environment and load conditions. In high-wear and high-corrosion environments, it is recommended to choose a thicker chrome plating layer to enhance the durability of the roller. If possible, try to improve the working environment to reduce the effects of corrosiveness and temperature on the chrome plating layer. For example, the damage to the chrome plating layer caused by environmental factors can be reduced by ventilation, cooling or humidity control.

Secondly, regular inspection and maintenance of chrome plated rollers are the key to extending their service life. Through timely cleaning, repair and reasonable use, companies can reduce abnormal wear of rollers and extend their life. In addition, the quality of the chrome plating process directly affects the durability of the chrome plating layer. Choosing reputable suppliers and advanced electroplating technology can ensure the adhesion and uniformity of the chrome plating layer, thereby extending its service life.

Affordable, Custom-Engineered Rolls for Industrial Applications

At JH Machinery, we specialize in producing affordable, high-quality industrial rolls. From rubber rolls to chrome plated rollers, our products meet the highest standards of precision and durability. Our company’s manufacturing capabilities include advanced machinery like CNC lathes and automatic welding machines to ensure top-tier results. With a focus on customization, we provide tailored rolls to suit specific applications across industries such as printing, automotive testing, and metallurgy. Buy directly from our factory and take advantage of our prices competitive and bulk purchasing options. Get a quote today and save with our low-price offerings!