The Importance of Ceramic Anilox Roller for the Quality Stability of Flexplate Printing

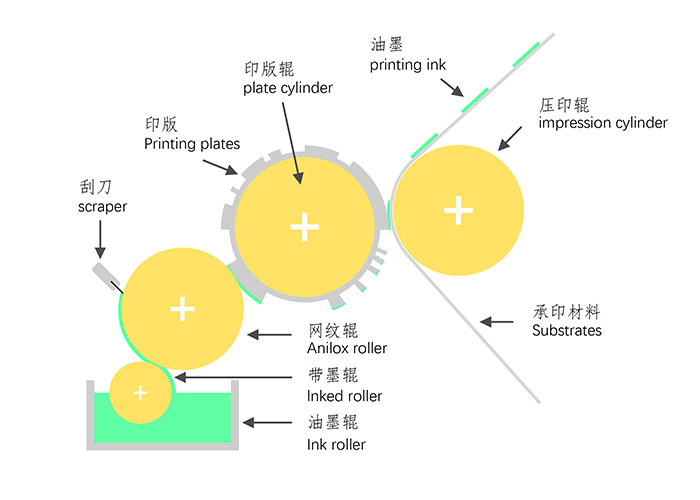

As the core component of flexographic printing equipment, ceramic anilox roller can provide quantitative ink for printing plate. Compared with the ink path design of offset printing and embossing, the short ink path design of flexographic printing (the ink is transferred to the printing plate through the anilox roller, and then transferred from the printing plate to the substrate) is shown in Figure 1, which is the main reason for its more stable color density. While other factors such as printing plate and ink remain unchanged, the anilox roller, as the starting point of the flexographic ink system, determines the color density of printing by its own parameters.

The American Flexographic Technology Association (FTA) once mentioned in an article that 90% of the color matching problems in flexographic printing are related to the anilox roller. Although this statement is slightly exaggerated, it is sufficient to illustrate the importance of ceramic anilox roller to the stability of flexographic printing quality