What is the manufacturing process of industrial cooling roller?

Industrial cooling roller is an indispensable and important component in many manufacturing industries. Whether in the fields of plastics, papermaking, printing or metal processing, cooling roller plays a key role in cooling, stabilizing and forming in the production process. Its manufacturing process is complex and precise, which directly affects the operating efficiency of the equipment and the quality of the final product.

This article will introduce the manufacturing process of industrial cooling roller in detail, and deeply explore the whole process from raw material selection to finished product processing.

What is the role of industrial cooling roller?

The main function of industrial cooling roller is to cool and control the temperature of materials during the production process. Cooling roller usually circulates cooling water or other cooling media internally to quickly take away the heat of the material, so as to achieve the purpose of stable production and improve product quality.

In the manufacturing process, the core tasks of cooling roller include:

● Cooling materials: quickly cool high-temperature materials to the required temperature.

● Maintain dimensional stability: ensure that the surface of the material is flat, without warping or deformation during the cooling process.

● Optimize product characteristics: improve the mechanical properties, surface finish and dimensional accuracy of the material through precise temperature control.

What is the manufacturing process of industrial cooling roller?

The manufacturing process of industrial cooling roller mainly includes material selection, cylinder forming, internal channel design, surface treatment and precision machining. The following is the specific manufacturing process:

1. Material selection

When manufacturing industrial cooling roller, the selection of materials is crucial. The material of cooling roller needs to have high strength, good thermal conductivity and corrosion resistance. Commonly used materials include:

● Carbon steel: relatively cheap, suitable for occasions with low corrosion resistance requirements.

● Stainless steel: has excellent corrosion resistance and is suitable for food processing and chemical industries.

● Aluminum alloy: light weight, good thermal conductivity, but suitable for lower working pressure.

● Special alloy steel: used in special scenarios that require high temperature resistance and wear resistance.

The choice of material depends on the specific use environment of cooling roller, such as working temperature, medium type and production process requirements.

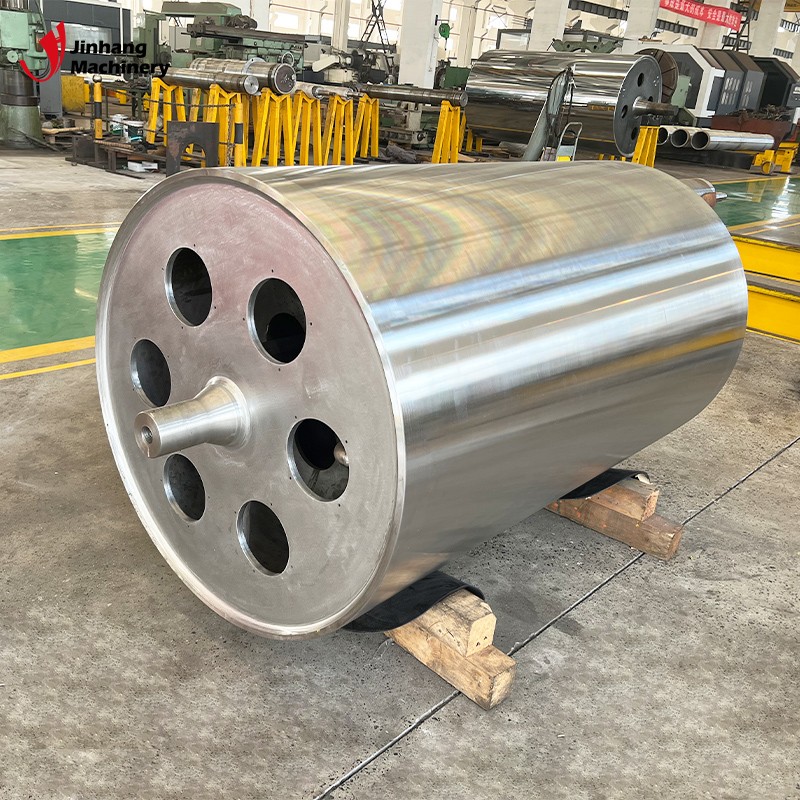

2. Cylinder forming

The cylinder is the main part of the industrial cooling roller, and its manufacturing process mainly includes the following steps:

(1) Forging or casting

Depending on the size and strength requirements of the cooling roller, forging or casting processes can be used:

● Forging: The roller blank is formed by high-temperature forging, which has higher strength and density.

● Casting: Suitable for manufacturing cooling rollers of large size or complex shape, with lower cost.

(2) Rough processing

The forged or cast blank is preliminarily turned and milled to achieve a shape close to the design size.

(3) Internal channel processing

The cooling roller needs to be designed with cooling channels to ensure the circulation of the cooling medium. The processing methods of the internal channel usually include:

● Drilling method: Drill holes along the length direction inside the roller to form a straight channel.

● Welding pipe: Welding the metal pipe to the inside of the roller for complex fluid distribution.

● The design of the channel needs to consider fluid mechanics and heat exchange efficiency to ensure uniform and rapid cooling effect.

3. Surface treatment

The surface properties of industrial cooling roller directly affect its cooling efficiency and material contact effect, so surface treatment is a very critical part of the manufacturing process.

(1) Polishing

The surface of the cooling roller can be made extremely smooth through mechanical polishing or electrolytic polishing. This not only helps to improve the heat transfer efficiency, but also reduces the possibility of material adhesion on the roller surface.

(2) Chrome plating or coating

In order to enhance the wear resistance and corrosion resistance of the cooling roller, the surface is usually chrome plated or coated with a corrosion-resistant coating. The chrome plating layer has high hardness and excellent wear resistance.

(3) Texture processing

In some special application scenarios, it is necessary to process textures on the surface of the cooling roller to enhance the grip of the material or increase the surface heat dissipation area.

4. Precision processing

The final processing of the industrial cooling roller requires high precision to ensure its stable operation during the production process and meet specific process requirements.

(1) Turning and grinding

Precision turning and grinding of the outer diameter of the roller to meet the design size requirements and ensure surface finish.

(2) Dynamic balancing calibration

The cooling roller needs to maintain balance during high-speed rotation to avoid vibration and noise. Dynamic balancing calibration adjusts the center of gravity of the roller by adding or removing balancing weights.

(3) Dimension inspection

The dimensions, tolerances and surface finish of the industrial cooling roller are fully inspected by high-precision measuring equipment to ensure that the finished product meets the design standards.

5. Assembly and testing

After the cooling roller is manufactured, it is also necessary to perform assembly and performance testing to ensure that it can meet the actual working conditions.

(1) Bearing installation

High-precision bearings are installed at both ends of the cooling roller to ensure that it can rotate smoothly.

(2) Fluid test

The sealing and flow properties of the internal channel are tested by injecting cooling medium to eliminate possible leakage risks.

(3) Trial run

Trial run is performed under simulated working conditions to detect the operating stability and cooling effect of the cooling roller.

What are the key challenges in manufacturing industrial cooling rollers?

There are several key challenges that require special attention in the manufacturing process of industrial cooling rollers:

● Precision machining of cooling channels: The design and machining of cooling channels directly affect the efficiency of cooling rollers. A narrow channel may cause obstruction of medium flow, while a wide channel will reduce the heat exchange efficiency.

● Surface quality control: The finish and uniformity of the coating on the surface of the cooling roller are critical to its performance. Any slight defect may cause scratches or adhesion of the material during the cooling process.

● Dynamic balancing accuracy: Cooling rollers usually rotate at high speeds, and any slight imbalance will affect the production equipment and product quality.

Looking for affordable yet reliable industrial rolls?

JH Machinery produces a wide range of rolls including mirror-finished, electroplated, and polyurethane rolls, perfect for industries like metallurgy and printing. Our advanced manufacturing equipment and strict quality control ensure durability and precision. We provide factory-direct pricing, bulk order discounts, and professional warranty service including free repair or replacement for defects. Purchase from our China-based factory and take advantage of our current promotions.