Can the coating thickness of tungsten carbide rollers be customized?

Tungsten carbide rollers are widely used in industrial production due to their high strength, wear resistance and corrosion resistance. These rollers are used in many fields such as steel, papermaking, printing, textiles, and plastic processing, and undertake high-strength and high-precision work tasks. The thickness of the coating directly affects the performance and service life of the roller. Therefore, in actual production, customizing the coating thickness becomes an important factor in the company's choice. So, can the coating thickness of tungsten carbide rollers be customized? If so, how is it achieved? This article will analyze in detail from multiple angles.

Can the coating thickness of tungsten carbide rollers be customized?

What is tungsten carbide roller coating?

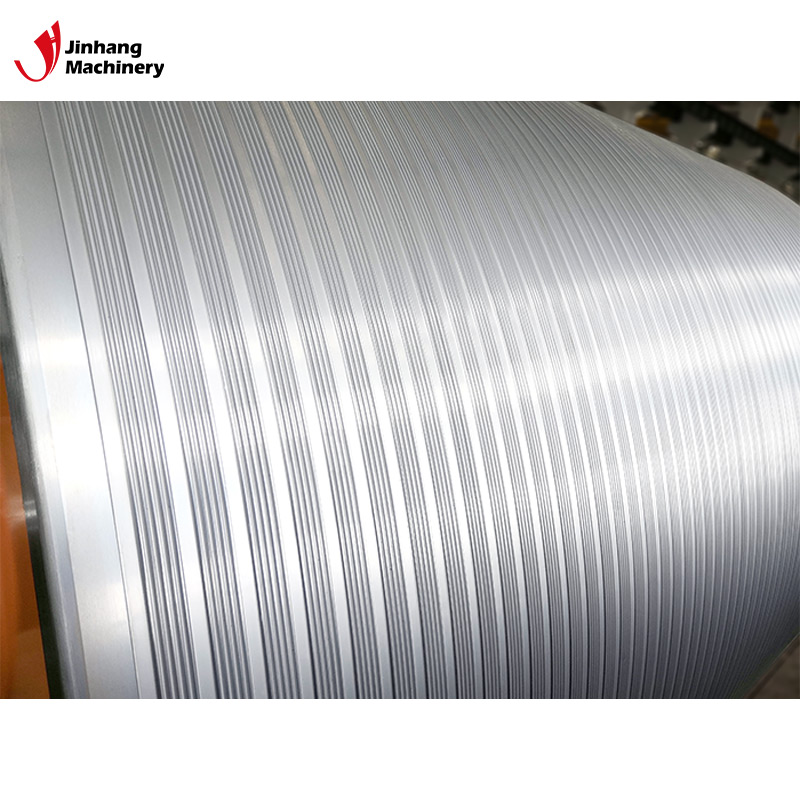

Tungsten carbide roller coating is a high-performance surface coating that evenly attaches tungsten carbide particles to the roller surface through processes such as plasma spraying, thermal spraying or high-velocity flame spraying (HVOF). Tungsten carbide has a hardness close to that of diamond and has excellent wear and corrosion resistance, so it is widely used in the manufacture of rollers that need to withstand extreme working environments.

Can the coating thickness be adjusted?

The answer is yes, the thickness of the coating on tungsten carbide rollers can be customized. Different working conditions and application scenarios have different performance requirements for rollers, which requires flexible adjustment in coating thickness. For example, in high-friction or high-corrosion environments, thicker coatings are required to extend service life; while in application scenarios that require high precision, thinner coatings may be required to reduce the impact on size.

How large is the customization range of coating thickness?

What is the usual coating thickness?

The thickness of tungsten carbide rollers is usually between 0.05mm and 1mm, but the actual range can be adjusted according to demand. The choice of thickness depends on the application requirements and the design of the roller:

1. Thin coating (0.05mm - 0.2mm)

Thin coatings are suitable for scenarios that require high precision and light weight, such as printing rollers or textile rollers. This coating not only provides sufficient hardness, but also maintains the original size and weight of the roller.

2. Medium-thickness coating (0.3mm - 0.6mm)

Coatings of this thickness are widely used in conventional industrial applications, such as rollers in papermaking and plastic processing. This thickness can take into account both wear resistance and economy.

3. Thick coating (0.7mm - 1mm or thicker)

Thick coatings are often used for rollers in extreme environments, such as calendering rollers in steel processing or chemical rollers in highly corrosive environments. Thicker coatings can significantly increase the service life of rollers.

How is the customization accuracy of coating thickness?

The high development of modern coating technology has enabled the thickness of tungsten carbide coatings to achieve extremely high customization accuracy, and the error is usually controlled within ±0.01mm. This high-precision thickness control can meet the stringent requirements of industrial equipment for roller performance.

How to achieve customization of coating thickness?

Coating thickness control method

1. Selection of spraying process

The thickness of tungsten carbide coating is mainly controlled by spraying process. Different spraying technologies can achieve different coating thicknesses. For example, high-velocity flame spraying (HVOF) is suitable for thick coating applications, while plasma spraying is more suitable for thin coating scenarios that require high precision.

2. Adjustment of the number of spraying times

The thickness of the tungsten carbide rollers coating is usually achieved by controlling the number of spraying times. Each spraying will increase a certain thickness, and the expected coating thickness can be achieved by repeated spraying.

3. Optimization of process parameters

Parameters such as temperature, pressure, and spraying speed in the spraying process will also affect the thickness of the coating. Accurate control of these parameters is the key to achieving customized coating thickness.

4. Subsequent processing

After the coating is sprayed, the coating thickness can be further accurately adjusted through subsequent processing methods such as grinding and polishing to meet the specific requirements of customers.

Effect of coating thickness on performance

What is the difference between thick and thin coatings?

Coating thickness has a significant impact on the performance of tungsten carbide rollers:

1. Wear resistance

A thicker coating generally has better wear resistance because it provides a larger material reserve that can resist friction and wear for a longer time.

2. Corrosion resistance

Thick coatings perform better in chemically corrosive environments because the thickness of the coating material increases the difficulty of penetration by the corrosive medium.

3. Thermal stability

Thick coatings are better able to resist thermal stresses, but may also increase the risk of thermal expansion. When used under high temperature conditions, the effect of coating thickness on thermal stability needs to be considered.

4. Surface finish

Thin coatings can generally achieve a higher surface finish after polishing. This is very important for some scenarios that require extremely high surface accuracy, such as precision printing.

5. Roller weight

Thicker coatings will significantly increase the weight of the roller, which may have an impact on the dynamic balance of some high-speed equipment.

How to choose the right coating thickness for tungsten carbide rollers?

Select according to the use scenario

1. High friction scenario

In high friction environments, such as calender rollers in steel processing or drying rollers in the paper industry, thicker coatings are required to extend service life.

2. High precision scenario

In printing, textiles and other scenarios with high requirements for surface finish and dimensional accuracy, thinner coatings should be selected to maintain the precision performance of the equipment.

3. Chemical corrosion environment

In the use of rollers in the chemical industry, thicker coatings can provide better corrosion protection.

Tungsten carbide roller coating thickness detection method

In order to ensure that the coating thickness meets the requirements, the following detection methods are commonly used:

1. Ultrasonic thickness gauge

Ultrasonic thickness gauges quickly measure the thickness of the coating through the time difference of sound wave reflection. This method is non-destructive and suitable for real-time detection on the production line.

2. Microscope section method

In the laboratory, the thickness of the coating can be accurately measured by observing the roller section under a microscope.

3. Eddy current measurement

The eddy current measurement method uses the principle of electromagnetic induction to quickly determine the thickness of non-conductive coatings, which is suitable for the detection of tungsten carbide coatings.

4. Weighing method

The weight difference of the roller before and after coating is measured. By calculating the coating density, the average thickness of the coating can be indirectly calculated.

Customized Industrial Rolls Factory with Global Shipping & Support

JH Machinery is a professional factory manufacturing customized industrial rolls with a variety of surface treatments and coatings. Serving sectors from packaging to mining, our rolls include rubber, tungsten carbide-coated, and polyurethane types, all engineered to exact specifications. We provide competitive factory prices, bulk discounts, and worldwide shipping options. Our after-sales team ensures responsive support and warranty services. Get your personalized quote and enjoy competitive pricing by buying directly from our China factory.