What is the difference between industrial heating roller and cooling roller?

In the industrial production process, rollers are an indispensable and important component, widely used in printing, plastic processing, papermaking, textile and food processing. According to different functions and uses, rollers can be divided into many types, among which industrial heating roller and cooling roller are two very common types of rollers. Although the appearance and structure of the two may be similar, there are significant differences in working principles, uses and technical characteristics.

This article will discuss the difference between industrial heating roller and cooling roller in detail from multiple aspects to help readers fully understand the characteristics and application scenarios of these two industrial rollers.

What is an industrial heating roller?

An industrial heating roller is an industrial equipment that heats the surface of the roller through an internal heating system. Its main function is to transfer heat to the contacted material, thereby changing the temperature and physical properties of the material. Heating rollers are usually used in process links that require heating or controlling the temperature of the material, such as hot pressing, thermoplastic molding and heat sealing.

What is an industrial cooling roller?

Industrial cooling rollers take away the heat from the surface of the roller through an internal cooling system, so that the contacted material can be cooled quickly. The main function of cooling roller is to stabilize the size of the material, accelerate the cooling process, improve production efficiency, and improve the quality of the finished product. It is often used in production links that require rapid cooling, such as film cooling, cooling after plastic extrusion, and curing after coating.

What is the working principle of industrial heating roller?

Industrial heating roller transfers heat to the surface of the roller through an internal heat source (such as an electric heating tube or hot oil) to form a uniform and controllable heating effect. The following are common heating methods for heating rollers:

● Electric heating: The resistance heating element is embedded in the roller body and generates heat through electric current, which is suitable for processes that require precise temperature control.

● Hot oil heating: By circulating heat-conducting oil in the roller, the heat is evenly distributed to the entire roller surface, which is suitable for uniform heating of a large area.

● Steam heating: Using the heat of steam to heat the roller body, it is suitable for high-temperature processes.

What is the working principle of industrial cooling roller?

Industrial cooling roller absorbs heat from the roller surface through an internal cooling medium (such as cold water, coolant or compressed air) and discharges the heat through a circulation system. Common cooling methods include:

● Water cooling: Absorbing heat through an internal circulating water system is the most common cooling method with high efficiency and stability.

● Air cooling: The heat of the roller body is taken away by high-pressure airflow, which is suitable for scenes with mild cooling or where liquid cooling cannot be used.

● Refrigerant cooling: Using a refrigerant circulation system in high-precision cooling can achieve extremely low temperature cooling effects.

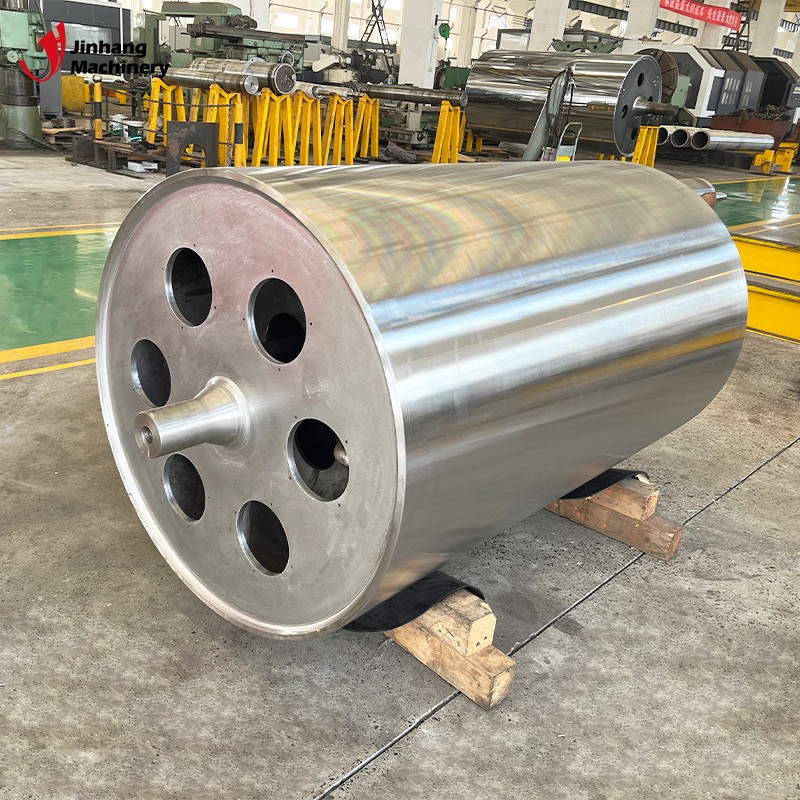

What are the structural characteristics of industrial heating rollers?

● Roller material: Usually metal materials with high thermal conductivity, such as aluminum alloy, carbon steel or stainless steel, are used to ensure that heat is quickly and evenly transferred to the surface.

● Heating system: Built-in heating elements or heat conduction pipes must have good thermal conductivity.

● Surface coating: To prevent heat loss or improve wear resistance, the surface of the heating roller is usually coated with special high-temperature resistant materials.

● Temperature control: Equipped with a precise temperature control system to ensure that the temperature fluctuates accurately within the set range.

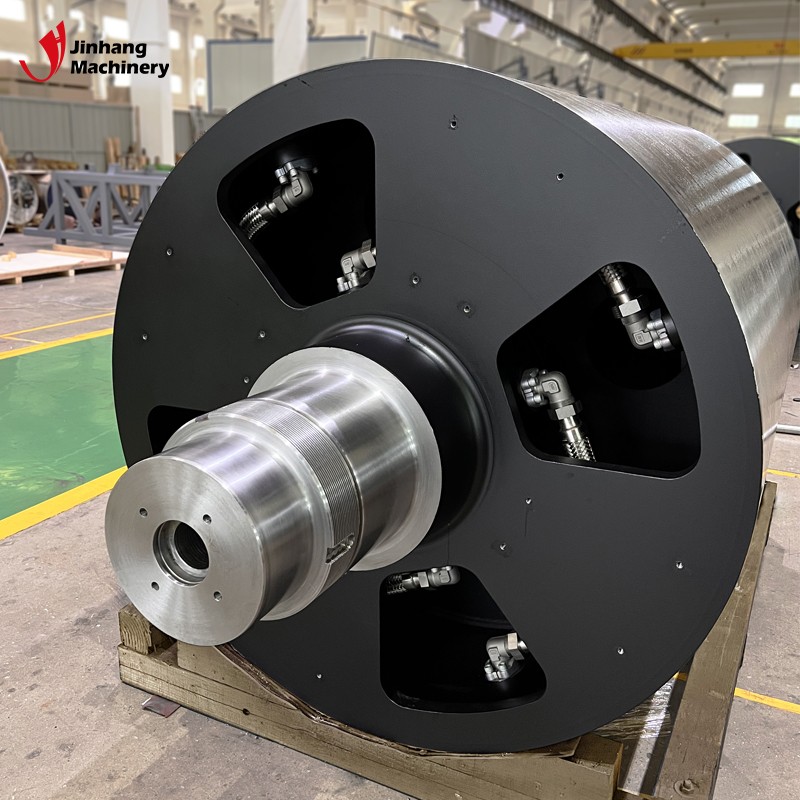

What are the structural characteristics of industrial cooling rollers?

● Roller material: Mostly use materials with strong thermal conductivity and corrosion resistance, such as aluminum, stainless steel or copper.

● Cooling medium system: Cooling channels are designed inside to ensure uniform distribution of cooling medium.

● Surface treatment: In order to improve cooling efficiency and corrosion resistance, the surface of the cooling roller may be coated with chrome plating or ceramic coating.

● Heat exchange efficiency: The design of the cooling roller focuses on heat conduction and heat dissipation efficiency, so the internal structure of the roller is relatively complex.

What are the application scenarios of industrial heating rollers?

Industrial heating rollers are usually used in process links that require heating or heat treatment, such as:

● Thermoplastic processing: The heating roller heats the material during the extrusion of plastic film and sheet to reach the plasticizing temperature.

● Textile finishing: Used to heat and shape fabrics to improve fabric quality and texture.

● Coating process: In the coating process, the heating roller is used to maintain the fluidity of the coating at a suitable temperature.

● Hot pressing: Apply heat and pressure to the material to form it into the desired shape.

What are the application scenarios of industrial cooling rollers?

Cooling rollers are mostly used in process links that require rapid cooling or cooling, such as:

● Film cooling: used for rapid cooling of plastic film after extrusion to prevent deformation or uneven stretching.

● Coating cooling: Use cooling rollers to solidify the coating after paper or film coating to improve the surface quality of the product.

● Cooling and shaping: Cool the material after thermoforming to stabilize the size and improve the strength.

● Food cooling: In food processing, it is used to cool food that has been heated during the production process to ensure safety and quality.

Industrial heating rollers and cooling rollers: performance comparison

| Features | Industrial heating roller | Industrial cooling roller |

| Functions | Heating materials, increasing temperature | Cooling materials, reducing temperature |

| Internal system | Heating elements (resistance, hot oil, steam) | Cooling channels (water, air, refrigerant) |

| Material | High thermal conductivity metal + high temperature resistant coating | High thermal conductivity metal + anti-corrosion coating |

| Usage environment | Processes requiring heat treatment | Processes that require rapid cooling |

| Energy consumption | Higher (electrical or thermal energy) | Low (water or air circulation) |

Precautions

● Choose the right roller type: When designing a production line, choose a heating roller or cooling roller based on specific process requirements. For example, a plastic extrusion process may require heating the plastic material with a heating roller first, and then solidifying and shaping it with a cooling roller.

● Maintenance and cleaning: Both heating rollers and cooling rollers require regular cleaning and maintenance. The heating roller should prevent overheating and damage to the internal components, while the cooling roller should avoid contamination or blockage of the cooling system.

● Control system accuracy: The temperature control system of heating roller and cooling roller directly affects the production quality. A high-precision temperature control system helps optimize process results and reduce energy waste.

China-Based Manufacturer of Industrial Rolls with OEM Services

JH Machinery offers OEM services for industrial rolls, producing high-quality rubber, polyurethane, and carbonized rolls to meet your design requirements. Our factory is equipped with modern machinery, including imported universal grinders and lathes, ensuring superior precision and surface finish. We provide wholesale prices, discounts on bulk orders, and promotional offers throughout the year. Buy direct from China to secure cost-effective, durable rolls with reliable after-sales warranties. Contact us for quotes and special purchasing plans today.