Does a Heating Roller Need to Maintain a Low Temperature Difference?

In modern continuous industrial production, whether it's film extrusion, metal calendering, rubber calendering, nonwoven fabric shaping, paper coating, or plastic calendering, the heating roller is almost always a core temperature control component. It not only determines the temperature uniformity of the material but also directly affects the surface quality, thickness stability, and final processing performance of the product.

Therefore, the question of whether it's necessary to maintain a low temperature difference in the heating roller during production lines has always been a key technical issue of concern for equipment engineers, process engineers, and factory managers.

To answer this question more systematically, this article will comprehensively explain the structure of the heating roller, its heat transfer method, the impact of its thermal stability on the process, and the necessity of maintaining a low temperature difference, helping you to deeply understand the importance of heating roller temperature control.

Why Does the Temperature Difference of the Heating Roller Affect the Production Line?

To understand whether a production line needs to maintain a low temperature difference in the heating roller, we must start with the temperature control principle of the heating roller.

A heating roller is a roller whose internal temperature is maintained by heat transfer oil, steam, or electric heating. Its functions are:

• Providing a stable process temperature

• Heating or insulating materials in contact with the surface

• Adjusting the softening, plasticizing, or shaping of materials

• Ensuring processing accuracy through uniform roller surface temperature

However, heated rollers have an inherent technical challenge—temperature differences easily occur on the roller surface. These temperature differences typically include:

• Lengthwise temperature difference

• Circumferential temperature difference

• Temperature gradient between the surface and the interior

Any temperature difference exceeding the allowable process range can lead to uneven heating of the material, resulting in defects.

Therefore, whether heated rollers should maintain a low temperature difference operation is essentially a question of whether stable heat input is necessary for process accuracy.

Is maintaining a low temperature difference operation of heated rollers really necessary?

The answer is: Yes—most industrial production lines require maintaining a low temperature difference operation of heated rollers.

Why?

Because the heating rollers provide the thermal foundation for the entire process, any temperature difference will directly manifest in the material as:

• Uneven thickness

• Different surface gloss

• Changes in internal stress

• Inconsistent mechanical properties

• Surface defects (haze, uneven surfaces, localized sticking to the roller, etc.)

In other words, the greater the temperature difference of the heating rollers, the more difficult it is to control product quality.

This is especially true for industries requiring high surface consistency, high processing precision, and small thickness tolerances, where maintaining a low temperature difference is essential.

These include, but are not limited to:

• High-gloss film

• PET/BOPP film

• Various calendered sheets

• Mirror calendering process

• Coating and setting process

• Non-woven fabric heat setting

• Roller lamination, etc.

In these industries, the heating rollers not only need "temperature stability" but also "extremely low temperature difference between roller surface areas."

Therefore, maintaining a low temperature difference is not only necessary but also crucial for ensuring product consistency and yield.

What consequences will occur if the temperature difference of the heating rollers is too large?

Excessive temperature difference in the heating rollers will ultimately affect the material, primarily including:

1. Will material thickness fluctuations increase?

Yes.

Materials are softer and easier to thin at higher temperatures, and harder and more difficult to deform at lower temperatures.

Results:

• Increased thickness tolerance

• Uneven lateral thickness

• Decreased yield

In industries like film extrusion, uneven thickness can even lead to frequent online adjustments, impacting production capacity.

2. Will it cause inconsistent surface quality?

Yes, especially in calendering, mirror finish, or high-gloss production.

Different heating roller temperatures → different degrees of surface softening → affecting gloss, transparency, and smoothness.

Manifestations:

• One side is bright, the other is hazy (yin-yang effect)

• Localized excessively high or low gloss

• Orange peel texture, bright spots

All of these stem from temperature differences in the heating roller area.

3. Will it cause roller sticking or difficulty in demolding?

Yes.

In areas with low temperatures, the material is not fully softened, which can easily lead to:

• Excessive friction

• Localized adhesion

• Difficulty in localized detachment

This exacerbates surface damage and may also cause localized adhesive buildup on the roller surface.

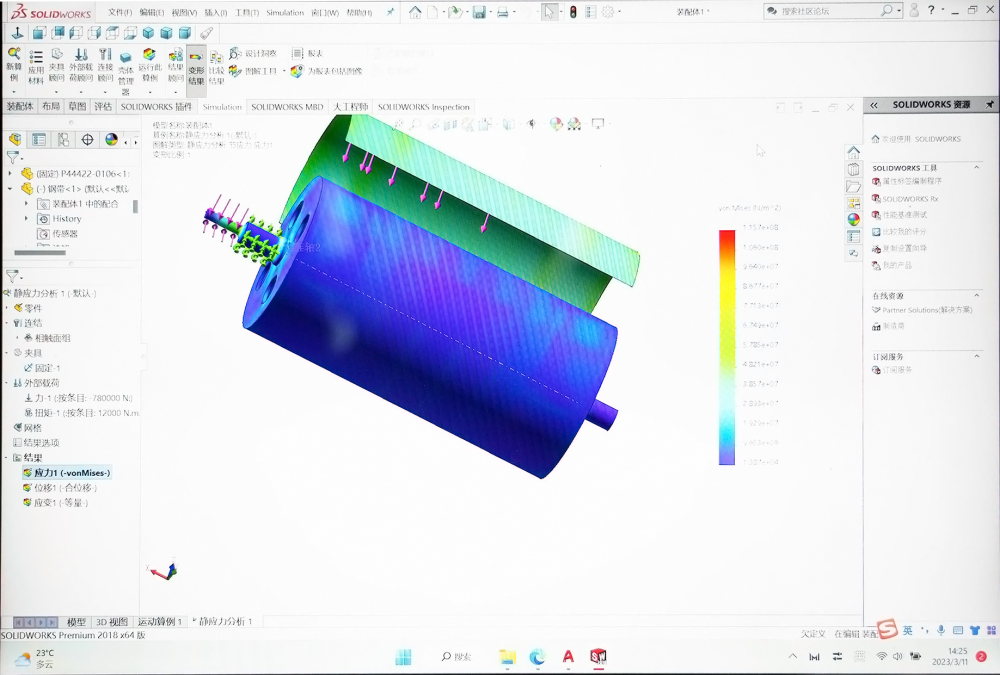

4. Will temperature differences in the heating rollers shorten equipment lifespan?

Indirectly yes.

Large temperature differences mean:

• Uneven thermal expansion

• Uneven bearing stress

• Localized stress concentration inside the roller

Over time, this will cause the heating rollers to prematurely exhibit:

• Deformation

• Surface damage

• Shortened bearing life

Therefore, temperature differences not only affect the product but also the reliability of the equipment.

What factors mainly cause temperature fluctuations in the heating rollers?

To maintain low temperature differences in the heating rollers, it is essential to understand the sources of these temperature differences.

Common factors include:

1. Temperature differences caused by uneven heating systems

Including:

• Poor hot oil circulation

• Uneven steam distribution

• Inappropriate electric heating tube layout

• Asymmetrical internal heat conduction paths

System structural defects can directly cause temperature differences on the roller surface.

2. Fluid Flow Rate and Direction Issues Inside the Heating Roller

Low flow rate → Low heat exchange efficiency

Unbalanced flow channel structure → Large temperature gradient

Poor internal design of the heating roller makes it difficult to achieve a low temperature difference.

3. Temperature Difference Caused by Uneven External Load

Including:

• Material tension differences

• Different contact times

• Uneven pressure distribution

• Inconsistent local heat absorption on the roller surface

These factors cause certain areas of the heating roller to cool down faster.

4. Variations in Production Line Ambient Temperature

For example, proximity to a ventilation opening on one side and a heat source on the other side can lead to external temperature differences.

5. Heating Roller Material and Wall Thickness Affect Thermal Uniformity

The better the thermal conductivity of the material and the more uniform the wall thickness, the easier it is to control the temperature difference.

Inferior rollers → Slow thermal response → Difficult to eliminate temperature differences.

How can the production line maintain a low temperature difference operation for the heating roller?

To ensure the heating roller maintains a low temperature difference operation, it is necessary to address three aspects: equipment design, process control, and maintenance.

The following is a systematic explanation from a professional perspective.

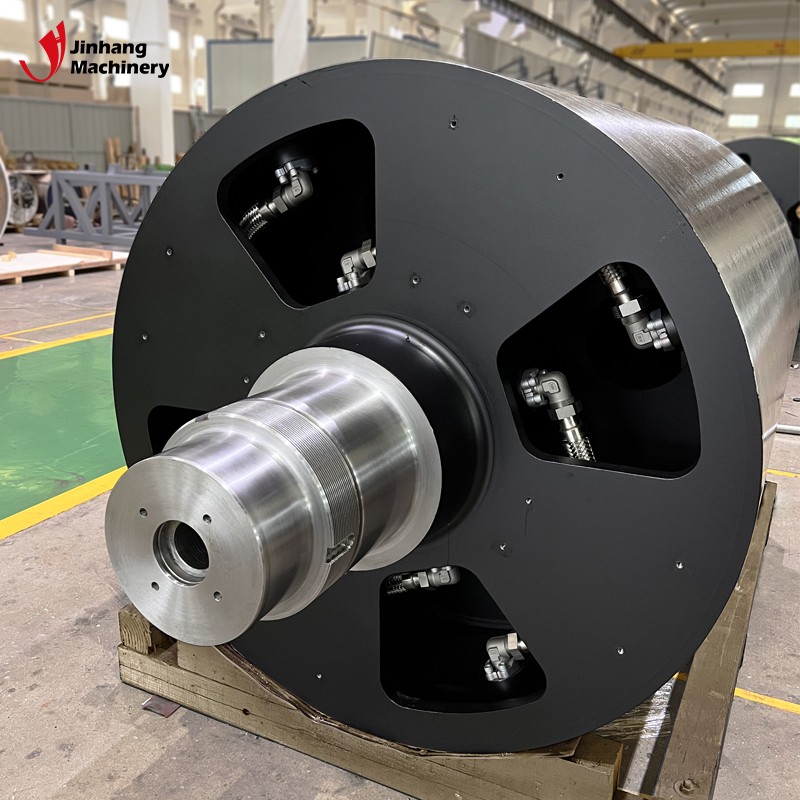

1. Selecting a High-Quality Heating Roller Body Structure

An excellent heating roller should possess at least:

• A well-designed internal flow channel

• Uniform wall thickness

• Good thermal conductivity

• Precision-machined axial structure

These directly determine whether the temperature difference can be kept within a low range.

2. Using a High-Performance Temperature Control System

A good temperature control system should possess:

• High flow rate

• Pressure stabilization capability

• Precise PID control

• Rapid compensation function

This achieves more accurate temperature compensation, maintaining stable operation of the heating roller.

3. Adjusting Process Parameters to Reduce the Impact of Temperature Difference

This includes:

• Balancing tension

• Controlling material flow speed

• Adjusting contact points and pressure distribution

• Avoiding localized overload

Process factors are often the key external factors causing temperature differences.

4. Regular Maintenance and Cleaning of the Heating Roller System

Maintenance includes:

• Cleaning internal flow channels

• Checking hot oil quality

• Calibrating temperature sensors

• Monitoring system flow rate

These maintenance steps directly contribute to long-term control of the heating roller temperature difference.

Are the temperature difference requirements the same for different types of heating rollers?

No.

Different heating rollers have different allowable temperature difference values depending on the application scenario.

Common types of heated rollers include:

1. Ordinary heated roller

Suitable for general heating processes. Tolerant temperature difference range: ±2℃~±5℃

2. Calendering heated roller (high gloss roller)

Requires extremely high surface quality. Temperature difference requirement: within ±0.5℃

3. Coating and setting heated roller

Requires uniform coating. Temperature difference requirement: ±1℃~±2℃

4. Calendering heated roller (rubber/plastic)

Temperature difference affects the degree of plasticization. Temperature difference requirement: ±1℃~±3℃

5. Steam heated roller

Temperature difference is generally more difficult to control than hot oil. Temperature difference requirement: ±2℃~±4℃

In summary, different industries have different requirements for the low temperature difference of heated rollers, but no industry allows operation with a temperature difference of μεγάλη.

What is the standard for low temperature difference operation of heated rollers?

There is no single answer to this question, but there are industry-standard reference values (arranged from most stringent to least stringent).

Application Type and Recommended Temperature Difference Control Values:

Mirror Calendering, Optical Films: ≤ ±0.5℃

High-Precision Calendering: ≤ ±1℃

Coating Industry: ≤ ±1℃~±2℃

General Films/Sheets: ≤ ±2℃

Industrial Heated Roller Processes: ≤ ±3℃~±5℃

However, the basic consensus is: Whenever the process requires surface quality, thickness uniformity, transparency, and flatness, the heated rollers must maintain a low temperature difference operation.

Is it necessary for the heated rollers to maintain a low temperature difference operation?

The final conclusion is very clear:

Yes, the production line must maintain a low temperature difference operation for the heated rollers.

The reasons include:

• Temperature differences directly affect the uniformity of material heating.

• They can cause uneven thickness, surface defects, and differences in mechanical properties.

• They can affect calendering effects, transparency, and gloss.

• They can reduce production line stability.

• They can increase equipment wear.

• They can decrease yield rates and increase production costs.

Therefore, from the perspectives of process, equipment lifespan, and quality management:

Maintaining a low temperature difference in the heating rollers is a crucial requirement that cannot be ignored in industrial production, and it is also a fundamental condition for ensuring product consistency and quality stability.