What are Rollers in Manufacturing?

In manufacturing, many pieces of equipment appear complex and technologically advanced, but their core operating logic is often built upon seemingly simple, basic components. Rollers are one such widely used yet often underestimated crucial component.

In numerous manufacturing fields, including film, papermaking, printing, textiles, metallurgy, rubber, plastics, composite materials, and electronic materials, industrial rollers are present throughout almost the entire production process from raw materials to finished products.

However, many people's understanding of "rollers" remains at the superficial level of "cylindrical rotating parts," neglecting their functional depth and technological significance within manufacturing systems.

So, the question arises: What exactly are rollers in manufacturing?

What role do industrial rollers play in the production process?

Why are industrial rollers indispensable in almost all continuous manufacturing processes?

This article will systematically answer the question "What are rollers in manufacturing?" from multiple dimensions, including basic definitions, structural characteristics, functional logic, type classification, and manufacturing requirements, helping you build a complete and professional understanding of industrial rollers.

What exactly is a roller in manufacturing?

From its most basic definition: A roller is a mechanical component with a cylindrical structure that can rotate around its own axis and directly participates in the material conveying, forming, or processing process.

When rollers are applied to industrial manufacturing systems and undertake continuous production tasks, they are usually called: Industrial rollers.

Unlike ordinary rollers or support shafts, industrial rollers are not merely "rotating" components, but highly functional process parts. They often come into direct contact with the materials being processed, and their surface condition, rotational stability, temperature, pressure, and geometric accuracy all directly affect the quality of the final product.

Therefore, in the context of manufacturing, "roller" is not a simple structural term, but a professional concept encompassing function, precision, process, and system synergy.

Why are industrial rollers ubiquitous in manufacturing?

A close examination of modern manufacturing production methods reveals a common thread: the vast majority of manufacturing processes are continuous, and continuous processes are inseparable from industrial rollers.

1. Continuous Manufacturing Requires a "Controllable Motion Carrier"

Many processes in manufacturing are not completed in a single step, but through multiple consecutive steps:

• Conveying

• Unfolding

• Calendering

• Stretching

• Cooling

• Heating

• Shaping

Industrial rollers are the core carriers that enable these continuous movements.

2. Industrial Rollers Enable Controllable Material Movement

During the manufacturing process, materials need to:

• Move at a predetermined speed

• Maintain stable tension

• Avoid deviation

• Prevent surface damage

Industrial rollers, through their structure and surface characteristics, achieve precise control over the material's motion.

3. Industrial Rollers are Direct Executors of Process Parameters

Process parameters such as temperature, pressure, speed, and surface condition ultimately need to be "implemented" through industrial rollers.

Therefore, industrial rollers are not passive parts, but process execution components.

What are the basic structural components of an industrial roller?

Although different types of industrial rollers vary greatly in function and form, structurally, most industrial rollers consist of the following basic parts:

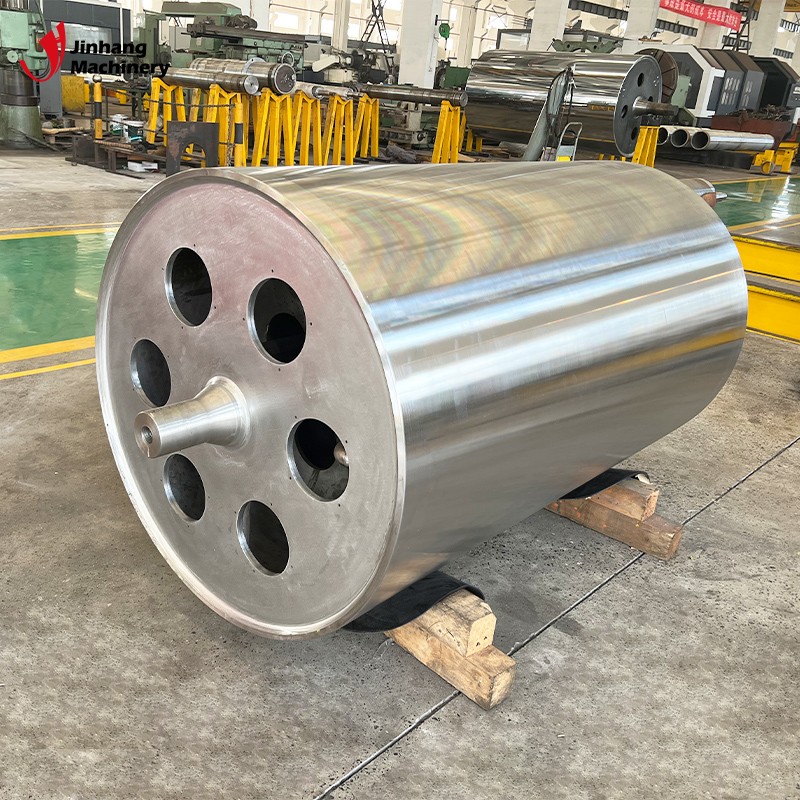

1. Roller Body

This is the core structure of the industrial roller, typically:

• Solid cylinder

• Hollow cylinder

The roller body determines the industrial roller's:

• Rigidity

• Strength

• Rotational stability

2. Shaft Ends or Connecting Structures

Industrial rollers need to be mounted on equipment, therefore, both ends are usually designed with:

• Shaft Ends

• Flanges

• Keyways

• Threads or other connecting structures

These structures ensure that the industrial roller can stably mesh with the equipment's transmission system.

3. Surface Functional Layers

This is the key part that distinguishes industrial rollers from ordinary mechanical shaft parts.

The surface of an industrial roller may be:

• Metallic mirror finish

• Rubber layer

• Coating (chrome plating, ceramic, tungsten carbide, etc.)

The surface condition directly determines the industrial roller's functionality.

4. Internal Structure (Optional)

Some industrial rollers may also include:

• Heating channels

• Cooling channels

• Reinforcing ribs

These internal designs enable industrial rollers to perform more processing tasks.

What are the core functions of industrial rollers during manufacturing?

Industrial rollers are not "single-function" components, but rather perform multiple critical tasks.

Are industrial rollers only used for conveying materials?

The answer is no.

While conveying is the most basic function of industrial rollers, it is far from all.

1. Conveying and Guiding Functions

Industrial rollers, through rotation, guide materials along a predetermined path and maintain directional stability.

2. Tension Control Functions

Through roller diameter, surface friction coefficient, and arrangement, industrial rollers help the system establish and maintain stable tension.

3. Surface Leveling and Correction Functions

For example, mirror-finish industrial rollers can be used to:

• Eliminate surface wrinkles

• Improve flatness

• Improve gloss

4. Heating or Cooling Functions

Heating and cooling rollers can directly participate in the heat treatment process of materials.

5. Calendering and Forming Functions

Some industrial rollers need to withstand high pressure to change the thickness or structure of materials.

How can industrial rollers be classified in manufacturing?

To better understand the diversity of industrial rollers, they can be classified from multiple dimensions.

Can industrial rollers be classified by function?

Yes, and this is the most common classification method.

Common functional industrial rollers include:

• Conveyor rollers

• Guide rollers

• Tension rollers

• Correction rollers

• Heating rollers

• Cooling rollers

• Mirror-finish rollers

• Calendering rollers

Can industrial rollers be classified by surface finish?

Yes, they can.

For example:

• Smooth industrial rollers

• Mirror-finish industrial rollers

• Rubber-coated industrial rollers

• Coated industrial rollers

The surface finish determines the contact method between the industrial roller and the material.

Can industrial rollers be classified by structural form?

Yes, they can be classified as:

• Solid industrial rollers

• Hollow industrial rollers

• Functional rollers with internal structures

What are the differences in requirements for industrial rollers under different working conditions?

Manufacturing processes are complex, and the requirements for industrial rollers vary greatly depending on the conditions.

1. High-Speed Operation

Industrial rollers require:

• High dynamic balance accuracy

• High coaxiality

• Stable structure

2. High-Temperature Operation

Industrial rollers require:

• Good heat resistance

• Thermal deformation control capability

3. High-Precision Surface Operation

Industrial rollers require:

• Extremely low surface roughness

• Surface consistency

4. High-Wear Operation

Industrial rollers require:

• High surface hardness

• Wear-resistant coating

What are the differences between industrial rollers and ordinary mechanical shaft parts?

This is one of the key questions to understanding "what is a roller in manufacturing?"

Ordinary shaft parts:

• Primarily transmit power

• Precision requirements are concentrated at mating parts

Industrial rollers:

• Directly participate in the process

• The entire outer surface is a "working surface"

• Precision, surface finish, and structure are all equally important

Therefore, the manufacturing logic of industrial rollers is far more complex than that of ordinary shaft parts.

Why must industrial rollers be custom-manufactured?

There are almost no universally applicable industrial rollers, due to reasons including:

• Different equipment structures

• Different process parameters

• Different material properties

• Different installation methods

Therefore, industrial rollers typically require custom design and manufacturing based on specific equipment and processes.

How should we understand the role of industrial rollers in manufacturing systems?

From a systems perspective, manufacturing is:

• Equipment is the skeleton

• The control system is the brain

• Industrial rollers are the "hands" that execute the process

Without industrial rollers, manufacturing systems would lose continuity and controllability.

What are rollers in manufacturing?

Rollers, especially industrial rollers, are core functional components in manufacturing used to achieve continuous conveying, process handling, and quality control.

They are not merely rotating cylinders, but also:

• Executors of process parameters

• Controllers of material conditions

• A crucial determinant of product quality

Only by truly understanding the structure, function, and manufacturing logic of industrial rollers can we deeply understand why modern manufacturing can achieve high-efficiency, high-consistency, and high-quality continuous production.