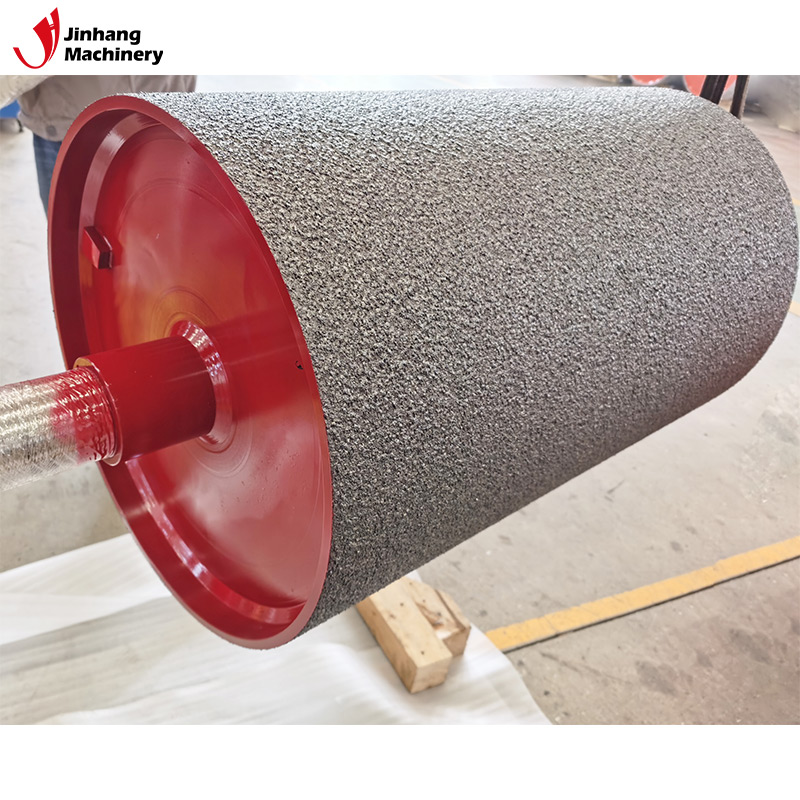

How to Apply Tungsten Carbide Coating to Industrial Rollers?

Tungsten carbide coatings, due to their extremely high hardness, excellent wear resistance, and good corrosion resistance, have become an important means of improving the lifespan and performance of industrial rollers. To obtain high-quality tungsten carbide coated rollers, it is necessary not only to select appropriate powder and spraying processes, but also to strictly control pretreatment, spraying parameters, post-treatment, and quality inspection.

This article systematically explains the key technical points of the entire process, from process selection to on-site implementation, quality control, and troubleshooting of common faults, helping engineers and maintenance personnel master the technical route for applying tungsten carbide coatings to industrial rollers.

What is a Tungsten Carbide Coated Roller? Why is the Process Flow So Important?

A tungsten carbide coated roller is a roller surface coated with a composite coating consisting of tungsten carbide (WC) and a metallic binder phase (such as Co, Ni, or NiCr) to achieve wear resistance, corrosion resistance, and a long service life. The tungsten carbide coating has a complex structure; improper spraying and post-treatment can lead to problems such as coating peeling, high porosity, and poor toughness. Therefore, full-process control is crucial.

What are the key steps in the preparation stage of a tungsten carbide coated roller?

1. Substrate Material Confirmation

• Common substrates: alloy steel, stainless steel, carbon steel, etc.

• Confirm the thermal expansion coefficient, hardness, and weldability of the substrate material to facilitate powder selection and process matching.

2. Machining and Finishing

• Machining to the required diameter, tolerances, and concentricity; ensuring dynamic balance allowance.

• Surface roughness is pre-determined according to the spraying process requirements (Ra can be coarser before sandblasting).

3. Chemical and Cleaning Treatment

• Degreasing and oil removal with solvents (such as acetone) and washing with deionized water.

• Preventing surface oil and cutting fluid residue from causing poor adhesion.

4. Sandblasting (Shot Peening) Roughening Treatment

• Common media: alumina or steel shot (particle size depends on the coating process).

• Target surface roughness (R_a or Rz) depends on the spraying process: generally 30–80 μm (profile height) for HVOF/partial melt of the undercoat/mechanical bonding.

• Sandblasting must be followed by immediate coating or spraying to prevent oxidation or contamination.

5. Preheating and Fixture Assembly

• For large-diameter rollers, proper preheating (depending on the process) can reduce thermal shock and residual stress.

• Fixtures should ensure dynamic balance and smooth rotation during spraying.

Which spraying process is most suitable for tungsten carbide coated rollers?

Common spraying processes include: HVOF (High-Speed Oxy-Fuel) spraying, plasma spraying, flame spraying, and cold spraying. Their characteristics are as follows:

1. HVOF (High-Speed Oxy-Fuel)

• Advantages: Dense coating, high adhesion, low oxidation, high hardness; suitable as the mainstream process for high-wear-resistant tungsten carbide coated rollers.

• Commonly used powders: WC-Co-Cr, WC-Co, WC-Ni series particles.

2. Plasma Spraying

• Advantages: Wide applicability, can spray thicker coatings; however, oxidation may be higher than with HVOF.

3. Cold Spray Coating

• Advantages: Low-temperature preparation, minimal heat-affected zone; requires high WC particle shaping, more suitable for special applications.

4. Flame Spray Coating

• Suitable for cost-sensitive applications or those with less stringent density requirements, but generally not the preferred high-end tungsten carbide coating process.

In summary, for tungsten carbide coated rollers requiring high density and adhesion, HVOF technology is the preferred choice.

How to Choose the Spray Powder for Tungsten Carbide Coated Rollers?

1. Mainstream grades such as WC-10Co-4Cr, WC-12Co, WC-17Co, and WC-Ni:

• Co series: Good toughness and impact resistance; commonly used in high-load, wear-resistant applications.

• Ni/NiCr series: Strong corrosion resistance, suitable for harsh chemical environments.

• The addition of Cr improves oxidation resistance and resistance to abrasive erosion.

2. Particle Size and Morphology:

• Atomized or spray-granulated spherical particles are beneficial for the stability of the caulking and spraying process.

• Particle size distribution affects spraying efficiency and coating density, commonly ranging from 15–45 μm.

3. Powder Preparation Methods:

• Sintering + atomization, mechanical coating (WC particles coated with a metallic binder phase), etc., aim to ensure a uniform distribution of WC and the metallic binder phase.

How to Control the Spraying Parameters of Tungsten Carbide Coating Rollers?

Key Parameters and Their Control Strategies (Taking HVOF as an Example):

• Flame temperature and flow rate: Determine the powder melting/semi-melting behavior; too high a temperature causes oxidation, while too low a temperature leads to poor adhesion.

• Distance from spray gun to workpiece: Affects particle velocity and temperature, typically 200–450 mm.

• Powder feed rate: Matches the flame energy to avoid cold particle impact or over-melting.

• Matrix rotation speed and overlap ratio: Determine the uniformity of coating thickness and interlayer bonding.

• Coating Thickness Control: Each coating layer is typically 50–150 μm thick, with the overall coating thickness usually ranging from 200–1200 μm, depending on the application.

• Multi-Layer Strategy: A thin metal bond coat can be applied first, followed by the main WC layer to improve adhesion.

Strict test spraying and parameter optimization are crucial for ensuring the quality of the tungsten carbide coated roller process.

What post-treatments are required after tungsten carbide coated roller coating?

1. Curing/Tempering Treatment (Depending on the process)

Used to release residual stress and improve bond strength (Note that the temperature should not induce substrate annealing or generate harmful phases).

2. Mechanical Leveling and Grinding

The coated surface is usually rough after spraying, requiring coarse grinding → fine grinding → ultra-fine grinding to achieve the desired geometry and roughness (Ra value).

For mirror-finish tungsten carbide coated rollers, grinding and polishing to Ra 0.2 μm or better are often required, depending on the application.

3. Heat Treatment and Annealing Control

Control residual stress at the coating-substrate interface to prevent delamination.

4. Surface Treatment/Sealing

Some applications use penetrating sealants or specialized coatings for surface passivation to reduce the impact of porosity on the process medium.

How to Inspect the Quality of Tungsten Carbide Coated Rolls?

1. Appearance and Geometric Inspection

Inspect the coating thickness uniformity, surface color, cracks, and delamination for visual defects.

Measure the coating thickness distribution using a thickness gauge (ultrasonic or magnetic induction).

2. Surface Roughness (Ra) Measurement

Use a roughness meter to check if the coating surface meets process requirements.

3. Microstructure and Porosity Inspection

Examine cross-sections for metallographic observation of coating density, particle morphology, and interfacial bonding.

Porosity below 1–3% is a high-quality indicator (depending on the process).

4. Hardness Measurement

HV or HRA, typical WC-Co coating hardness can reach 800–1200 HV (depending on grade).

5. Adhesion Strength Test

Pull-off test or micro-shear test to assess whether the adhesion meets specifications.

6. Residual Stress and Thermal Cycling Test

Residual stress is determined by XRD or porosity, and thermal cycling is performed to test resistance to thermal shock.

7. Dynamic Balancing Test

Dynamic balancing must be performed after final processing to ensure minimal vibration during high-speed operation.

Common Faults and Troubleshooting of Tungsten Carbide Coating Rollers?

1. Coating Peeling/Falling

• Causes: Surface contamination, insufficient sandblasting, missing adhesive layer, excessive thermal shock.

• Solution: Rework to remove the old coating, re-sandblast, apply a primer, optimize spraying parameters, and temper.

2. Cracks/Brittle Fracture

• Causes: Coating too brittle, high residual stress, mismatch in thermal expansion between substrate and coating.

• Solutions: Reduce coating thickness, improve binder ratio, anneal, or control cooling rate.

3. High Porosity/Adsorbed Residue

• Causes: Insufficient spraying energy or powder quality issues.

• Solutions: Increase flame energy, change powder, perform pore sealing.

4. Substandard Surface Roughness

• Causes: Improper post-grinding and polishing process or unsuitable coating particle size.

• Solutions: Optimize grinding sequence and tools, or use finer-grained powder before coating.

What are the key points for on-site implementation and safety of tungsten carbide coating rollers?

1. Environment and Ventilation: The spraying site must have good ventilation and particle control to prevent dust explosions and harmful fumes.

2. Fire Prevention and High Temperature Risk Management: Strict fuel or power management is required for HVOF and plasma spraying equipment.

3. Personal Protective Equipment: Operators should wear appropriate breathing apparatus, protective goggles, heat-resistant gloves, and protective clothing.

4. Powder Management: Powder should be protected from moisture and contamination, managed in batches, and stored properly.

5. Equipment Maintenance: Daily inspection and calibration of the spray gun, powder supply system, and combustion system.

6. Quality Records and Traceability: Each tungsten carbide coated roller should have documentation including the spraying batch, parameters, inspection report, and heat treatment records.

What are the key points to achieving high-quality tungsten carbide coated rollers?

To obtain excellent tungsten carbide coated rollers, the following aspects must be addressed:

• Rigorous substrate preparation and cleaning;

• Appropriate selection of powder (WC-Co/WC-Ni/WC-Co-Cr, etc.) and particle size;

• Prioritization of spraying processes that can create dense layers, such as HVOF;

• Precise control of spraying parameters and multi-layer stacking strategies;

• Appropriate post-treatment (curing, grinding, polishing, heat treatment) and dynamic balancing;

• Comprehensive quality inspection (thickness, porosity, hardness, adhesion, roughness);

• Strict safety and on-site management measures.

Through this systematic process, tungsten carbide coated rollers can exhibit excellent wear resistance, corrosion resistance, and stable operating performance under actual working conditions.