What are Carbide-Coated Rollers Used For?

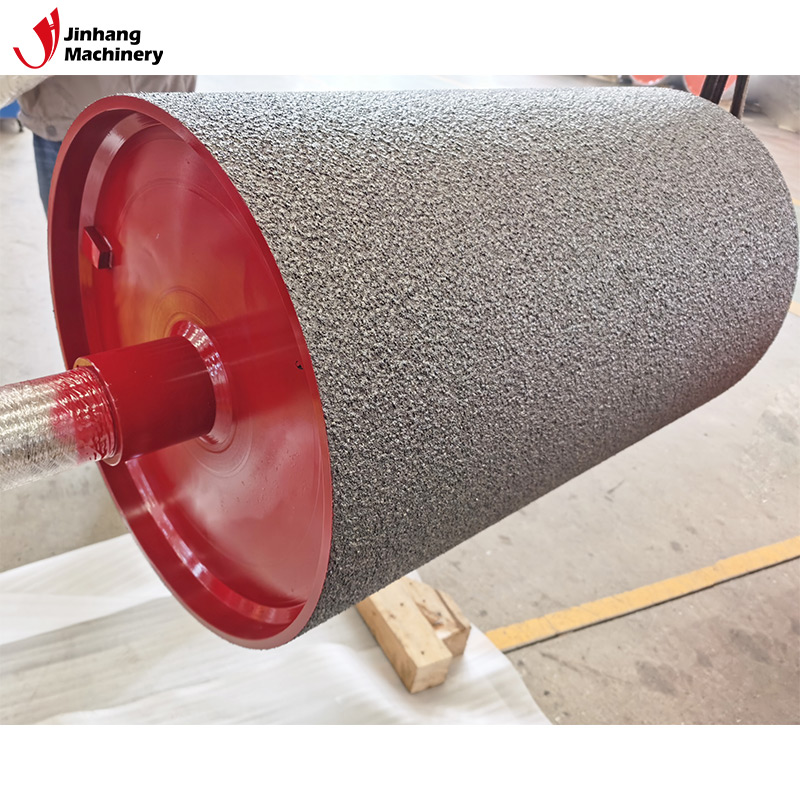

Carbide-coated rollers are crucial roller products in modern industry for enhancing wear resistance, corrosion resistance, service life, and processing stability. They are typically coated with a hard alloy layer composed of elements such as tungsten, chromium, and titanium through processes like HVOF (High-Speed Oxygen Fuel Spraying), plasma spraying, and PVD/CVD, giving the roller surface extremely high hardness and wear resistance.

Carbide-coated rollers are almost indispensable key components in film extrusion, calendering, coating, papermaking, metal processing, lithium battery separators, textiles, rubber roller replacement, and packaging material production.

Their primary purpose is to ensure that the roller surface maintains extremely low wear and stable performance under high-speed operation, high pressure, high friction, high corrosion, or high temperature environments, thereby ensuring consistent product quality.

Next, we will systematically answer from multiple perspectives: What are carbide-coated rollers used for? Why are they needed? What performance advantages do they bring?

Why do industrial equipment require carbide-coated rollers?

What processing pain points do they solve?

Many processing scenarios in industrial production place extremely stringent requirements on roller surfaces, which ordinary steel rollers, stainless steel rollers, and chrome-plated rollers often cannot meet. This is the fundamental reason for the emergence of carbide-coated rollers.

1. Ordinary steel rollers have poor wear resistance and are easily scratched and worn

In high-speed friction environments:

• Ordinary steel will wear down.

• Chrome-plated rollers, due to their thin coating, are also prone to peeling.

• Long-term use leads to increased roughness.

Carbide-coated rollers can achieve a surface hardness of HV1200–1500, far exceeding that of ordinary chrome plating (around HV800), effectively preventing wear.

2. Metal surfaces are easily corroded in highly corrosive environments

For example:

• Solvent-based coatings

• Strong acid and weak alkali slurries

• High-temperature oxidation environments

Carbide-coated rollers resist most chemical corrosion, significantly extending their service life.

3. High-Pressure Processing Requires a Highly Compressible Surface

In processes such as rubber calendering, metal rolling, and film thickness control, rollers withstand tens of tons of pressure, making it nearly impossible for ordinary surfaces to withstand the pressure for long periods.

The high strength of carbide coatings precisely solves this problem.

4. Preventing Product Surface Contamination or Adhesion

Some materials easily stick to rollers, causing bubbles, scratches, and film surface defects. Carbide-coated rollers create a low-friction, non-adhesive working surface.

Therefore, "carbide-coated rollers" are essentially designed to solve problems such as wear, corrosion, adhesion, pressure damage, coating peeling, and short lifespan.

What are the core functions of carbide-coated rollers? What are they specifically used for?

Although carbide-coated rollers appear simple in structure, they actually perform core functions in industrial production.

The following elaborates on five key functional dimensions:

1. The primary function of carbide-coated rollers: Improving wear resistance and significantly extending roller lifespan

Wear resistance is the most critical performance characteristic of carbide-coated rollers.

Why is wear resistance so important?

Because the rollers are in constant contact with the material:

• Friction

• Extrusion

• Particle impact

• Auxiliary doctor blade contact

Surface wear will lead to:

• Uneven thickness

• Reduced surface finish

• Roller marks appearing on the product

• Increased product scrap rate

Hard alloy coatings are more than 50% harder than chrome plating, therefore they can:

• Extend service life by 3–5 times

• Improve product surface consistency

• Reduce maintenance costs

This is one of its core purposes.

2. The second function of hard alloy coated rollers: corrosion resistance, suitable for solvents, acids, alkalis, and high humidity environments

Many industries involve highly corrosive substances, such as:

• Solvents in the coating industry

• Metal sheet cleaning solutions

• Chemicals in the paper industry

• Dispersants in lithium battery separator manufacturing

• Pigments, adhesives, and inks

Ordinary steel rollers will corrode in these environments, while hard alloy coatings have high resistance to most chemicals and can remain stable over a long period.

3. The third function of carbide-coated rollers: Anti-adhesion, reducing material sticking to the roller

Some processed materials are highly adhesive:

• EVA

• Glue

• Glue roller residue

• Plastic film

• Certain slurries

The low surface energy and special structure of carbide-coated rollers significantly reduce adhesion, with advantages including:

• Reduced material residue

• Prevention of film surface scratches

• Improved stable operation

• Reduced cleaning frequency

This is something that ordinary surfaces cannot achieve.

4. The fourth function of carbide-coated rollers: Scratch prevention, ensuring material surface quality

The surface of carbide-coated rollers is hard and dense, resisting scratches from particles. Especially in the film industry, any scratch can lead to product scrap.

Carbide-coated rollers can:

• Resistant to scratches

• Resistant to particle impacts

• Less prone to point or linear scratches

This is extremely important for optical films, lithium battery separators, food-grade films, etc.

5. The Fifth Function of Carbide-Coated Rollers: Enhancing Friction Performance and Stability

Different materials require different coefficients of friction for rollers. Carbide coatings can precisely control friction, ensuring:

• No material slippage

• No stretching instability

• Stable tension

• Consistent processing accuracy

Therefore, it plays a crucial role in stabilizing transmission.

In which industries are carbide-coated rollers used? Are their applications widespread?

Carbide-coated rollers have a very wide range of applications, covering almost all industries requiring wear resistance, corrosion resistance, anti-adhesion, and high-pressure processing resistance.

Below, we explain its uses by industry:

1. Plastic Film Industry (BOPET, BOPP, CPP)

Carbide-coated rollers are used for:

• Traction rollers

• Speed control rollers

• Calendering rollers

• Thickness measuring rollers

The purpose is to maintain a smooth, flat film surface, preventing scratches.

2. Coating, Laminating, and Embossing Industries

Commonly used in:

• Coating rollers

• Support rollers

• Glue roller replacement

Applications:

• Solvent resistance

• Improved coating uniformity

• Prevents glue adhesion

3. Papermaking Machinery

Used in:

• Press rollers

• Sizing rollers

• Guide rollers

Applications:

• Corrosion resistance

• Extended lifespan

• Maintaining a smooth press surface

4. Metalworking (Steel and Aluminum Plate Processing)

Used in:

• Cleaning rollers

• Oiling rollers

• Drying rollers

• Conveyor rollers

Applications:

• Resistance to strong acids and alkalis

• Preventing scratches on roller surfaces by hard metals

5. Lithium-ion Battery Separator and Materials Industry

Most typical requirements:

• High wear resistance

• High hardness

• Anti-adhesion

• Resistance to particle abrasion

Applications:

• Precision tension control

• Stable film feeding

• Avoid scratching the diaphragm.

In these applications, carbide-coated rollers are almost standard equipment.

6. Textile and Nonwoven Fabric Processing

In high-speed, high-friction environments:

• Prevents wear

• Prevents linear abrasion marks

• Improves material conveying stability

7. Packaging Materials and Rubber Calendering Industry

Under high-pressure processing:

• Carbide-coated rollers can replace high-cost rollers

• Improves wear resistance

• Maintains stable calendering thickness

What types of coatings are available for carbide-coated rollers?

What are the different coatings used for?

Different applications require different coating materials.

1. Tungsten-based Carbide (WC-Co) Coating

Applications:

• Ultra-high wear resistance

• Metal processing

• Thin film traction

Most commonly used.

2. Chromium-based Carbide (Cr3C2-NiCr) Coating

Applications:

• High-temperature environments

• Corrosion resistance

Commonly used in papermaking and metal pretreatment.

3. TiN/TiC/TiCN Coating

Applications:

• High hardness

• Anti-adhesion

Suitable for processing sticky materials.

4. Nickel-based Superalloy Coating

Applications:

• High strength

• Corrosion resistance

Suitable for solvent environments.

Different coatings address different working conditions.

What are the advantages of carbide-coated rollers compared to chrome-plated rollers?

Why are more and more factories choosing them?

Chrome-plated rollers are inexpensive, but have significant limitations:

• Insufficient hardness

• Prone to corrosion

• Prone to delamination

• Short lifespan

• Unstable friction

Advantages of carbide-coated rollers:

• 3–5 times longer lifespan

• Higher surface hardness

• Low adhesion

• Chemical corrosion resistance

• High temperature stability

• Less prone to delamination

Therefore, it has a wider range of applications and more stable performance.

Do carbide-coated rollers require maintenance?

What risks are associated with not maintaining them?

Although the coating is powerful, it is not maintenance-free.

Neglecting maintenance will result in:

• Increased surface roughness

• Unstable friction

• Localized corrosion

• Shortened service life

• Material misalignment and instability

• Increased product defects

Main maintenance items:

• Regular cleaning

• Avoid using metal tools for scraping

• Check bearing runout

• Prevent particles from entering the processing area

• Avoid contact with strong acid solutions

The more critical the process, the more rigorous the maintenance required for carbide-coated rollers.

Summary of the functions of carbide-coated rollers: What are they used for?

In summary of all their uses, they are mainly used for:

1. Improving wear resistance

Preventing roller wear and maintaining stable surface quality.

2. Improving corrosion resistance

Ensuring long-term stable operation in chemical environments.

3. Preventing adhesion

Reducing material adhesion to the roller and improving processing efficiency.

4. Improving scratch resistance

Preventing surface damage caused by impurities and particles.

5. Maintaining frictional stability

Used for tension control and transmission stability.

6. Extend equipment lifespan and reduce downtime for maintenance

Improve economic efficiency and production stability.

In short:

The function of carbide-coated rollers is to provide a stable, wear-resistant, corrosion-resistant, and high-strength roller surface under various harsh working conditions, ensuring product quality and stable equipment operation.