What Are the Uses of Industrial Tungsten Carbide Rollers?

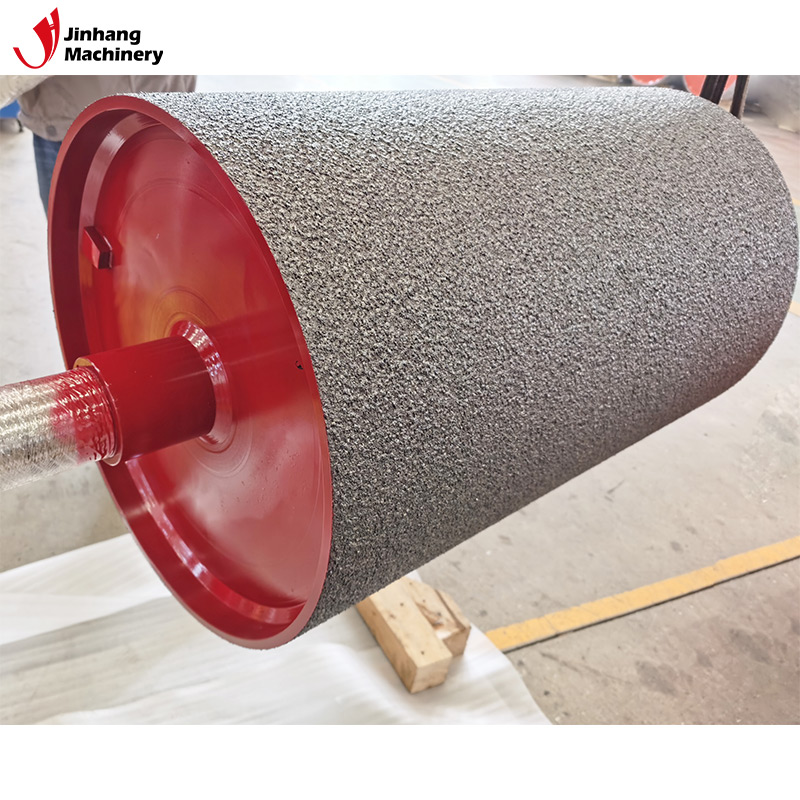

In modern industrial production, the performance of roller equipment directly affects the forming quality, surface accuracy, dimensional stability, and production efficiency of materials. Among them, tungsten carbide coating rollers are widely used in high-wear, high-load, and high-precision applications, and are one of the most wear-resistant, longest-lasting, and most stable high-end rollers available.

Tungsten carbide coated rollers feature:

• Extremely high hardness (HV1200–1400)

• Excellent wear resistance

• Good corrosion resistance

• Excellent pressure bearing capacity

• Stable surface roughness retention

• Suitable for high temperature, high speed, and high wear conditions

Due to these advantages, tungsten carbide coated rollers have become core roller components in many industries, undertaking critical tasks such as precision rolling, coating, guiding, supporting, tension control, calendering, thickness control, and forming.

This article will provide a complete and systematic answer to the following questions: What are the uses of industrial tungsten carbide coating rollers? Why are they widely used? In which working conditions are they irreplaceable?

Why is industrial production inseparable from tungsten carbide coating rollers?

Before understanding the uses, it is essential to understand the importance of tungsten carbide coating rollers:

• Ordinary chrome-plated rollers have a limited lifespan and are prone to wear.

• Polished steel rollers lack sufficient wear resistance.

• Ordinary rollers are prone to failure under high temperature and high speed conditions.

• Corrosive materials reduce roller lifespan.

Tungsten carbide coated rollers effectively solve these problems.

Their coatings often utilize:

• HVOF high-velocity oxy-fuel spraying

• APS plasma spraying

• Supersonic powder metallurgy coating

• High-hardness ultra-fine grain tungsten carbide structure

This forms a hard and dense wear-resistant layer, allowing the roller to remain stable even under extreme working conditions.

Therefore, the uses of tungsten carbide coating rollers are highly dependent on their material properties, and we will analyze their role in various industries in detail below.

Why are tungsten carbide coating rollers used in high-wear applications?

Tungsten carbide coated rollers have extremely high hardness, reaching:

• 1200–1400 HV (significantly higher than chrome-plated rollers at 800–1000 HV)

This hardness makes them particularly suitable for:

• Plastic materials with fillers

• Metal powders or materials containing particles

• High-friction contact surfaces

• Films with high surface tension

• Coating materials containing solid particles

• Products sensitive to surface damage

Ordinary chrome-plated rollers are easily scratched in these environments, while tungsten carbide coating rollers can maintain surface integrity and smoothness for a long time, thus extending service life and improving quality stability.

Are tungsten carbide coating rollers suitable for high-temperature applications?

This is a question many companies ask.

The answer is: very suitable.

Tungsten carbide coatings have excellent hardness stability and do not soften due to high temperatures, making them suitable for:

• Hot pressing

• Hot lamination

• Heat setting

• High-temperature steam environments

• High heat transfer scenarios

• High-temperature thermoplastic material production

When processing temperatures are high, ordinary rollers will experience the following due to thermal effects:

• Decreased surface hardness

• Coating peeling

• Surface discoloration

• Coating fatigue

Tungsten carbide coated rollers, however, maintain good performance, and are therefore widely used in high-temperature calendering and heat treatment processes.

Why are tungsten carbide coated rollers particularly suitable for high-tension applications?

Many films, metal foils, and paper-based materials require processing under high tension conditions.

High tension means:

• The roller surface bears greater pressure

• Higher contact stress

• Faster surface wear rate

Tungsten carbide coated rollers have very high compressive strength and hardness, allowing them to maintain stable dimensional accuracy and surface condition in high-tension environments, making them ideal rollers for high-tension applications.

Can tungsten carbide coated rollers be used in high-speed equipment?

High-speed operation leads to:

• Increased friction

• Increased temperature

• Increased vibration

• Surface fatigue

The dense structure and high hardness of tungsten carbide coatings allow them to maintain the following under high-speed conditions:

• Lower wear

• Higher fatigue resistance

• Stable surface roughness

• Lower frictional deformation

Therefore, it is widely used in high-speed industrial equipment.

What materials are best processed using tungsten carbide rollers?

One of the most prominent uses of tungsten carbide rollers is in processing abrasive materials, including but not limited to:

1. Plastic films

For example:

• PET

• BOPP

• CPP

• Optical films

• Coated films

• Thermoplastic materials

Its advantage is the ability to maintain a stable mirror or micro-texture structure.

2. Metal foils

Such as:

• Aluminum foil

• Copper foil

• Stainless steel thin sheets

Metal materials cause significant wear on ordinary rollers, while tungsten carbide coated rollers can operate stably for a long time.

3. Composite materials

Many composite materials contain:

• Fillers

• Hard particles

• Fiber structures

These reduce the lifespan of ordinary rollers, while tungsten carbide coated rollers can effectively handle them.

4. Coated materials

Including coating liquids containing solid particles, functional coatings, chemical coating processes, etc.

The tungsten carbide coated surface is not easily scratched, making it ideal for coating processes.

What are the uses of tungsten carbide rollers in calendering processes?

Calendering is one of the most common uses of tungsten carbide rollers.

In the calendering process, tungsten carbide rollers can be used for:

• Thickness control

• Surface polishing

• Providing texture

• Controlling material tension

• Maintaining material surface quality

• Providing uniform pressure

Due to its wear resistance, the calendering equipment can maintain a good surface condition for a long time, reducing the number of roller changes and improving production stability.

Can tungsten carbide rollers be used in coating processes?

The answer is: absolutely, and they are the preferred type of roller.

The requirements for rollers in coating processes include:

• Uniform surface

• Non-stick

• Resistance to chemical corrosion

• Stable surface roughness

• Wear resistance

• Continuously maintaining a stable texture or mirror finish

Tungsten carbide coated rollers have excellent chemical stability and wear resistance, making them particularly suitable for:

• Roll coating

• Reverse coating

• Transfer coating

• Homogenizing coating

• Functional film coating

• Lithium battery coating systems

This is one of the core applications where tungsten carbide rollers are widely used.

Are tungsten carbide rollers suitable for paper processing?

Yes, and the effect is excellent.

Paper processing involves:

• Fiber friction

• Continuous high-speed operation

• High-pressure roller gaps

• Surface treatment

Tungsten carbide coated rollers effectively reduce wear, increase service life, maintain the quality of paper calendering, and make surface brightness and flatness more stable.

What are the uses of tungsten carbide rollers in metal foil processing?

Metal foils (such as aluminum foil and copper foil) cause strong wear on the roller surface, so the uses of tungsten carbide rollers include:

• Metal foil calendering

• Thickness control

• Surface finishing

• Rolling micro-textures

• Preventing roller surface scratches

• Maintaining high gloss

Ordinary chrome-plated rollers are easily worn under metal foil materials, while tungsten carbide rollers can maintain stable performance for a long time, making them a key component in metal foil production lines.

Are tungsten carbide rollers used in the lithium battery industry?

Tungsten carbide coated rollers are extremely widely used in lithium battery manufacturing.

The reasons include:

• Wear resistance

• Maintaining stable rolling thickness

• Surface is not easily scratched by powder

• High hardness prevents micro-damage to the roller surface

• Suitable for processing slurries containing solid particles

Therefore, in the lithium battery industry, tungsten carbide rollers have become a commonly used type of roller.

Why are tungsten carbide rollers suitable for corrosive environments?

Some industries involve acids, bases, or chemical solvents, which can corrode ordinary rollers. Tungsten carbide coatings offer:

• Stable chemical inertness

• Excellent corrosion resistance

• Strong oxidation resistance

Therefore, they offer significant advantages in chemical engineering, coatings, adhesives, and functional materials production.

Are tungsten carbide rollers suitable for long-life applications?

This is one of their most prominent uses.

Due to the high hardness, wear resistance, and strong chemical stability of tungsten carbide coatings, they are suitable for all processes requiring a long roller lifespan. This significantly reduces the frequency of roller replacement and improves production stability.

Can you support customized rubber roller production?

Yes. As a dedicated rubber roller manufacturer, we provide full customization based on drawings, operating load, coating hardness, rubber formulation, and application environment. We use high-precision grinders and advanced rubber bonding technology to create rollers with excellent elasticity, stability, and wear resistance.

These rollers are widely used in laminating, printing, sheet manufacturing, and film processing. We ensure every rubber roller undergoes hardness testing, surface roughness inspection, and dynamic balancing before delivery.