Water-Guiding and Oil-Guiding Heating Rollers: Which Heats up Faster?

In industries such as film extrusion, coating, calendering, lamination, lithium battery separators, rubber and plastic calendering, chemical fiber spinning, papermaking, and composite packaging, heating rollers are crucial equipment for stabilizing process temperatures. Heating rollers deliver a heat-conducting medium through internal channels, allowing the roller body to reach a set temperature, thereby heating, shaping, or maintaining a constant temperature for materials.

Currently, the most commonly used heating rollers in industry are mainly divided into two categories:

• Heat-conducting oil heating rollers (oil-conducting heating rollers)

• Water-conducting heating rollers (hot water heating rollers)

Many users ask when selecting a model:

"Which heats up faster, an oil-conducting heating roller or a water-conducting heating roller?"

"Why do some industries prefer hot water, while others insist on using heat-conducting oil?"

"What are the differences in heating speed when changing the medium for the same heating roller structure?"

This article will analyze the differences in heating speed between these two types of heating rollers based on industrial principles, helping you make the right judgment from a technical perspective.

Why are heating rollers a key piece of equipment affecting heating speed?

The speed and uniformity with which the heating roller reaches the set temperature directly affects:

• Film crystallization rate

• Coating leveling properties

• Thickness stability of calendered products

• Coating drying and curing efficiency

• Material adhesion to the roller

• Time cost required for start-up and heating

The heating roller's heating rate depends not only on the medium but also on the following factors:

• Roller material (45# steel, alloy steel, stainless steel)

• Wall thickness and structure

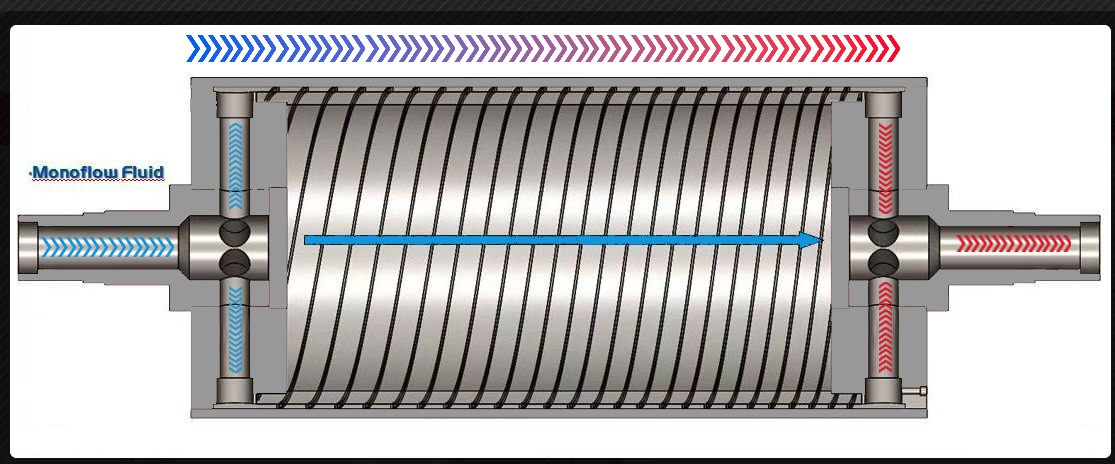

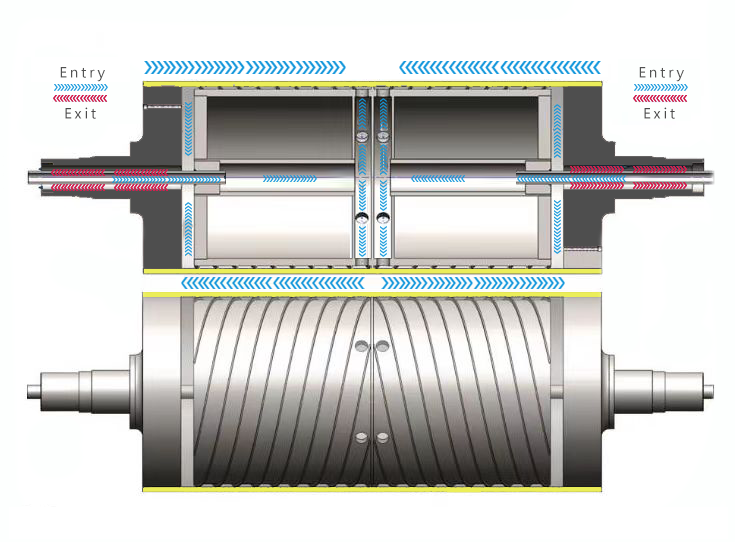

• Internal spiral or double-layer flow channel design

• Heat source supply capacity

• Medium circulation speed

However, despite these variables, the thermal properties of the medium itself remain the key basis for determining whether an oil-conducting heating roller or a water-conducting heating roller heats up faster.

What are the fundamental differences between the heat transfer media used in heating rollers?

To compare heating rates, it is essential to first understand the differences between heat transfer oil and hot water from a physical property perspective.

The most critical physical properties affecting heating rate include:

• Specific heat capacity

• Thermal conductivity (heat transfer rate)

• Thermal stability temperature range

• Boiling point or upper limit of usable temperature

• Flowability and viscosity

• System safety

The following are the basic characteristics of the two types of media:

Parameters | Hot water | Thermal oil |

| Specific heat capacity | High | Medium |

| Thermal conductivity | High | Slightly low |

| Viscosity | Low | Very variable with temperature |

| Permissible temperature | ≤180℃ (standard) | Can reach 250–350℃ |

| Safety | High | Requires leak prevention and oxidation control |

| Heating method | Steam or hot water machine | Thermal oil heater |

Based on the above basic data, you can probably guess:

Hot water usually heats up faster in the low-temperature range (≤150℃).

Thermal oil only shows its advantage in the high-temperature range (>180℃), but the heating rate is not necessarily faster.

The following is a detailed explanation using industrial thermodynamics logic.

Why do many industries say "hot water heats up faster than thermal oil"?

The answer is simple:

Hot water has a much higher specific heat capacity and thermal conductivity than heat transfer oil.

• Hot water absorbs heat quickly.

• Hot water releases heat quickly.

• Hot water transfers heat quickly upon contact with metal.

Therefore, in low-to-medium temperature operating conditions, such as:

• PVC calendering at 60~120℃

• Water-based coating at 60~90℃

• Papermaking and composite processing at 80~140℃

Hot water almost always heats up faster than heat transfer oil.

If short start-up times and fast heating response are required, factories generally prefer hot water heating rollers.

Which heats up faster, oil-heated rollers or water-heated rollers?

Heating roller heating speed comparison: Hot water vs. heat transfer oil

Based on industrial heat conduction and the structural mechanism of heating rollers, the question can be broken down into three key aspects:

1. Does the difference in thermal conductivity within the heating roller affect the heating speed?

Yes, and the difference is quite significant. The following are the thermal conductivity coefficients of common media:

• Water: 0.6 W/m·K

• Thermal conductivity of heat transfer oil: 0.12–0.15 W/m·K

This indicates that: Hot water conducts heat approximately 4–5 times faster than heat transfer oil.

Therefore:

• Hot water heating roller → The medium transfers heat to the roller body more quickly → The roller body heats up faster.

• Oil heating roller → Heat transfer is slower → The heating rate is naturally slower.

Under the same conditions, the heating rate of a hot water heating roller can typically be 20%–60% faster.

2. Does the difference in flow resistance within the heating roller affect the heating rate?

Yes, and it is an important structural factor.

Hot water has extremely low viscosity → low circulation resistance

• Water flows easily at high speed in the heating roller channel

• High heat exchange efficiency

• Uniform heating of the roller body

• Rapid and even temperature distribution

Heat transfer oil viscosity changes greatly with temperature → greater resistance

• Difficult circulation at initial low temperatures

• Low heat transfer efficiency

• Requires a longer time for the oil temperature to reach the "optimal flow range"

• Significantly slower temperature rise in the low-temperature range

Therefore, the hot water heating roller has a greater speed advantage in the initial startup phase.

3. Will different target temperatures of the heating rollers affect the judgment?

This is the key logic for judging the heating speed of the two.

It must be discussed in terms of temperature range:

(A) Low-temperature condition: ≤120℃ → Hot water heating roller is definitely faster

Reasons:

• Hot water transfers heat quickly

• Hot water has low circulation resistance

• Hot water heating systems generally have higher power

• The temperature range is within the advantageous range of water

Under low-temperature conditions, the hot water heating roller wins almost indisputably.

(B) Medium Temperature Conditions: 120–180℃ → Hot Water Still Heats Faster

Although hot water is close to its operating limit at 180℃, within the usable range:

• Hot water still transfers heat faster than heat transfer oil.

• The roller heats up faster.

• The medium circulation efficiency is higher.

Therefore, where some equipment allows, the hot water system still has a speed advantage in medium temperature conditions.

(C) High Temperature Conditions: ≥200℃ → Hot Water Cannot Be Achieved, Only Heat Transfer Oil is Available

When the temperature requirement exceeds 180℃:

• Hot water is no longer suitable.

• Excessive steam pressure is dangerous.

• The system is uneconomical.

At this time, heat transfer oil is the only option.

However, it must be emphasized that:

Even in the high-temperature range, the fact that the heat transfer oil heating roller "can reach high temperatures" does not mean that it "heats up faster."

It is simply "the only medium that can achieve high temperatures."

Final Conclusion

Within a comparable temperature range: the heating rate of the hot water heating roller is always faster than that of the oil heating roller.

This is determined by thermophysical parameters, not by usage experience. When the temperature requirement exceeds the allowable range of hot water, only thermal oil can be chosen, even if the speed is slower.

Which industries choose hot water heating rollers? (Based on temperature requirements, not trends)

We will not mention trends, only the corresponding temperature requirements.

Hot water heating rollers are commonly used for:

• Plastic film shaping at 60–120℃

• PVC calendering

• Heat-sensitive material production

• Water-based coating drying

• Paper hot pressing and shaping

• Flexible packaging lamination

• Chemical fiber pretreatment

• Paper front-end drying

These industries have high requirements for heating speed and are sensitive to safety, and hot water meets these requirements.

Which industries must use thermal oil heating rollers?

Because of the high temperature requirements (≥200℃), common applications include:

• High-temperature film processing for PET, PA, etc.

• High-temperature drying

• High-temperature calendering

• Engineering plastic calendering

• High-temperature sections of lithium battery separators

• Curing of thermosetting coatings

These processes have temperatures far exceeding the safe range of hot water, therefore, heat-conducting oil-heated rollers must be selected.

What process impacts will slow heating of the heating rollers cause?

Slow heating of the heating rollers will lead to:

• Increased start-up waiting time

• Inability of materials to quickly reach the process crystallization window

• Large thickness fluctuations

• Unstable surface quality

• Reduced production cycle time

• Increased equipment energy consumption

• Increased costs

Especially in coating, calendering, and extrusion processes, the heating rate directly determines start-up efficiency.

The Importance of Temperature Control System to Heating Roller Heating Speed

The main factors affecting the heating roller heating speed include:

• Heat source power (thermal oil heater/hot water machine)

• Flow channel structure (spiral, double-layer, homogenizing flow channel)

• Fluid circulation speed

• Roller wall thickness

• Real-time temperature recovery capability of the medium

With proper system configuration, the speed advantage of hot water heating rollers in the low-temperature range remains significant.

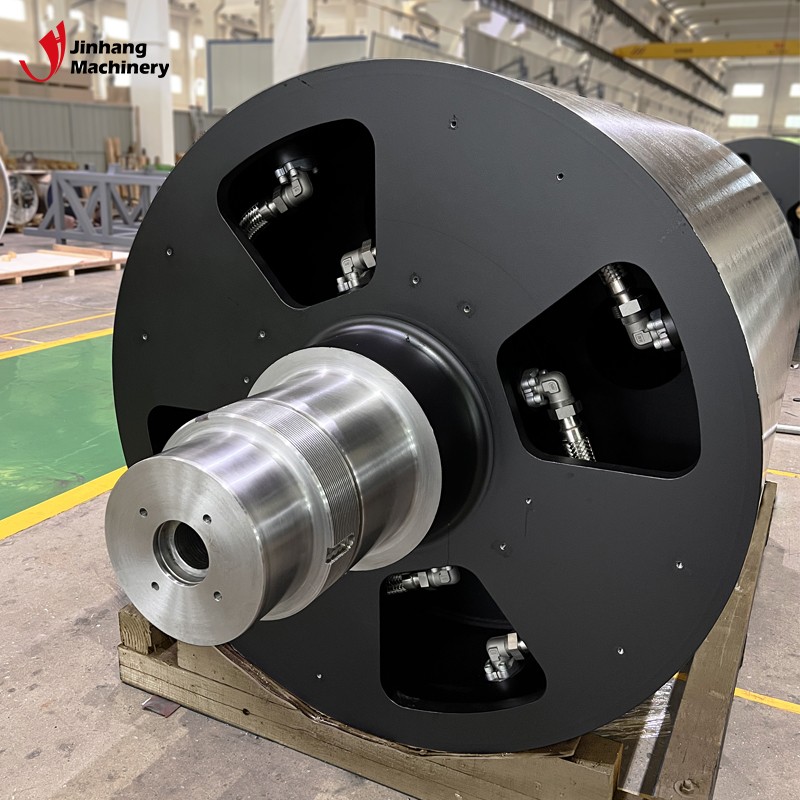

Does Jinhang Machinery offer custom roller solutions?

Yes. As a dedicated roller manufacturer, we specialize in custom machining based on client drawings or specific operational requirements. Whether you need special surface coatings, temperature-controlled rolls, precision-ground steel rolls, or application-specific polyurethane rollers, our engineers evaluate your equipment parameters and design the optimal roll structure.