What Are the Uses of EPDM Rubber Rollers?

In modern industrial equipment, rubber rollers are almost indispensable basic components. Different types of rubber have different performance characteristics, and EPDM rubber rollers (ethylene propylene rubber rollers) are widely used in many industries due to their excellent heat resistance, aging resistance, steam resistance, chemical resistance, and stable elasticity, making them a very important type of industrial roller material.

Many people know that EPDM is a high-performance rubber, but they are unclear about the specific uses of EPDM rubber rollers. Why do so many industries choose EPDM materials?

This article will provide systematic, in-depth, and professional answers to these questions.

Why are EPDM rubber rollers so widely used?

Before formally discussing "What are the uses of EPDM rubber rollers?", we need to understand the properties of EPDM itself that make it suitable for use as industrial rubber rollers.

The core advantages of EPDM include:

• Excellent heat resistance (continuous operation up to 150℃)

• Extremely strong steam resistance (withstands steam environments above 200℃)

• Excellent anti-aging and ozone resistance

• Good acid and alkali resistance and chemical corrosion resistance

• Good shock absorption and elasticity

• Excellent water resistance and low water absorption

• Good low-temperature flexibility

These properties enable EPDM rubber rollers to perform stably and are not prone to aging or damage in many working conditions with large temperature variations, high humidity and heat, and complex chemical media.

Next, we will comprehensively interpret the applications of EPDM rubber rollers from multiple industries and functional perspectives.

Which industries mainly use EPDM rubber rollers?

Due to their performance characteristics, EPDM rubber rollers play a key role in many fields such as printing, papermaking, textiles, plastics processing, chemicals, food processing, and metal handling.

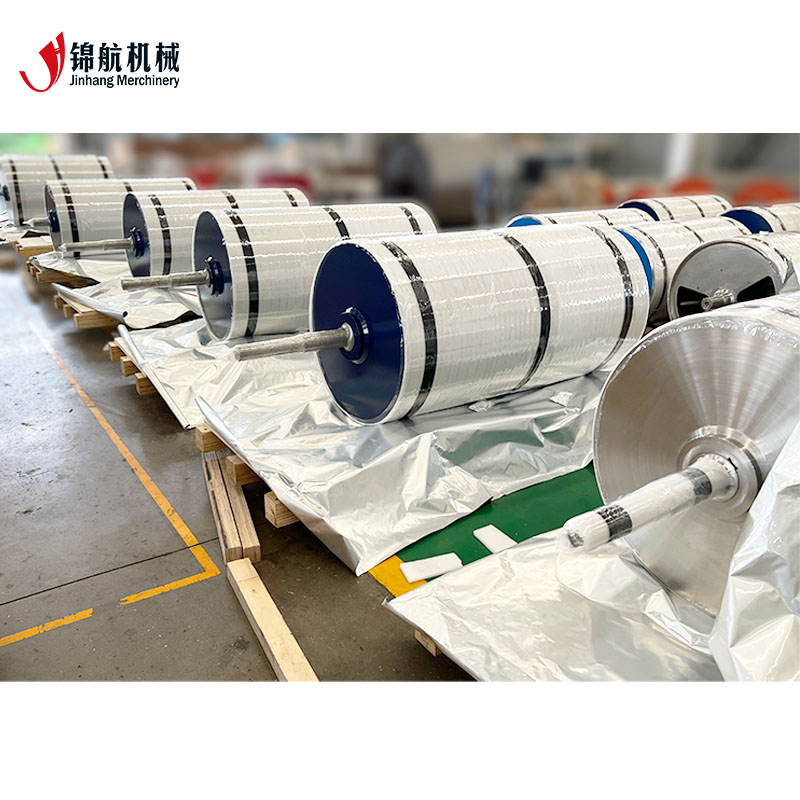

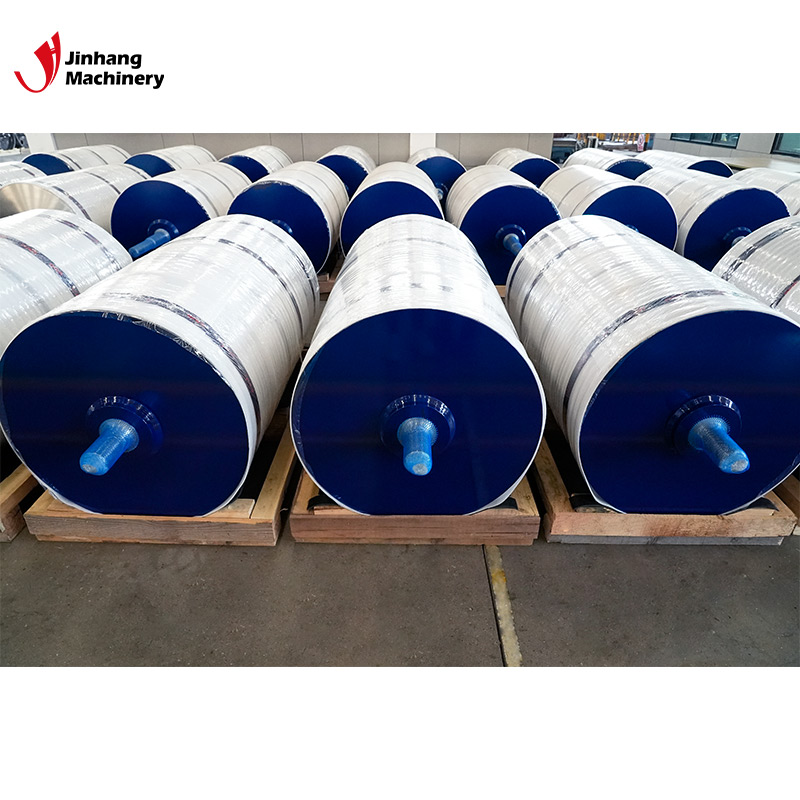

---- Jinhang Machinery, a high-quality industrial roller manufacturer from China, manufactures and processes various high-precision industrial rollers, including but not limited to rubber rollers. We support custom drawings; please contact us.

What are the uses of EPDM rubber rollers in the printing industry?

The printing industry is one of the important application areas for EPDM rubber rollers.

EPDM rubber rollers mainly perform the following functions in printing equipment:

• Paper conveying and guiding

• Ink transfer and even ink distribution

• Uniform application of coatings

• Imprinting or pressing actions

EPDM's ozone resistance and anti-aging properties are ideal for the long-term high-speed operation environment of printing equipment, while its chemical resistance resists the effects of ink solvents, cleaning agents, and adhesives.

Common types of EPDM printing rollers include:

• Conveyor rollers

• Ink distribution rollers

• Rollers for spray coating processes

• Cleaning system rollers

• Traction rollers This makes EPDM rubber rollers almost a standard material in the printing industry.

What role do EPDM rubber rollers play in the paper industry?

The paper industry requires a large number of machines related to humid and hot environments, steam, and high-temperature drying systems. EPDM performs stably in these environments, making its applications very wide-ranging.

EPDM rubber rollers are commonly used in papermaking production lines as:

• Guide rollers

• Pressure rollers

• Absorption rollers (non-vacuum, but with auxiliary dewatering function)

• Conveyor rollers in the drying zone

• Surface treatment rollers

High-temperature steam is used extensively in papermaking, and EPDM rubber rollers possess steam resistance, making them more durable and reliable than other rubbers (such as NBR and CR).

What are the key applications of EPDM rubber rollers in the textile industry?

The dyeing, setting, drying, and calendering processes in the textile industry place strict requirements on the heat and chemical resistance of rubber rollers.

EPDM rubber rollers are ideal for:

• Conveyor rollers in heat setting machines

• Drying section rollers

• Guide rollers in dyeing equipment

• Calendering rollers

• Rollers for coating or finishing processes

EPDM exhibits excellent resistance to acid and alkali solutions, dyes, and chemicals, making it a very stable rubber roller material in the textile industry.

What are the applications of EPDM rubber rollers in plastic film processing?

In plastic extrusion, calendering, casting, and stretching processes, a large number of conveyor rollers, pressure rollers, cooling rollers, and traction rollers are required.

EPDM rubber rollers are commonly used in these applications for:

• Conveying and traction of plastic films

• Rolling support in hot air drying sections

• Coating and laminating processes

• Online tension control rollers

• Guide rollers in heat treatment areas

EPDM's heat resistance and aging resistance ensure that the film surface is not contaminated, and there will be no rubber migration or adhesion problems, making it suitable for stable operation.

Why are EPDM rubber rollers suitable for the chemical industry?

Chemical production often involves contact with:

• Acidic substances

• Alkaline substances

• Salt solutions

• Various oxidizing agents

• Chemical vapors

• High-temperature environments

EPDM rubber rollers have superior chemical resistance compared to many rubber materials, therefore they are used for:

• Conveyor rollers in chemical production lines

• Rollers in chemical coating equipment

• Guide rollers in pipe extrusion

• Rollers in chemical liquid handling systems

EPDM's resistance to acidic and alkaline liquids extends its service life and makes it less susceptible to corrosion. Do EPDM rubber rollers work in the food processing industry?

Some food processing equipment does use EPDM rubber rollers.

The main reasons include:

• EPDM rubber is non-toxic

• Resistant to hot water and steam

• Does not easily produce odors

• Does not migrate harmful substances

EPDM rubber rollers are commonly used in the food industry for:

• Food conveyor lines

• Hot water cleaning equipment

• Guide rollers in heat treatment machinery

• Conveyor rollers in food packaging equipment

Food industry equipment frequently undergoes high-temperature steam cleaning, and EPDM's steam stability is superior to many rubbers, making it very suitable.

What are the uses of EPDM rubber rollers in the metal processing industry?

Metal surface treatments (such as cleaning, coating, drying, and spraying) require a large number of rubber rollers for conveying, guiding, and pressing functions.

EPDM rubber rollers are suitable for the following applications in metalworking lines:

• Surface cleaning line conveyor rollers

• Pre-plating equipment rollers

• Coating and spraying process conveyor rollers

• Drying line guide rollers

• Corrosion protection equipment rollers

Many cleaning agents contain acids, alkalis, or oxidizing chemicals, and EPDM has excellent resistance to these media, resulting in a longer service life.

What are the advantages of EPDM rubber rollers in humid, hot, or steamy environments?

Since many industrial sectors involve humid heat or steam, the steam resistance of EPDM rubber rollers deserves special emphasis.

The advantages of EPDM rubber rollers in high-temperature and humid environments are as follows:

• Withstands high-temperature steam (above 200°C)

• No change in appearance after nearly 100 hours in superheated steam at 230°C

• Strong resistance to hot air aging; will not crack prematurely due to temperature fluctuations

• Stable performance at high temperatures; will not soften or delaminate

• Strong resistance to water environments; does not absorb water or swell

Therefore, many equipment systems involving steam heating, hot air drying, and cleaning systems prioritize EPDM rubber rollers.

What functions do EPDM rubber rollers typically perform in equipment?

In any industry, EPDM rubber rollers commonly perform the following functional roles:

1. Conveying: Used for conveying paper, film, fabrics, metal sheets, food, etc.

2. Guiding: Helps materials maintain a stable trajectory.

3. Tensioning: EPDM rubber rollers can stabilize material tension through elasticity.

4. Pressing: Provides pressure during coating, laminating, and pressing processes.

5. Surface Modification: Plays a role in uniformly applying liquids or coatings in specific equipment.

6. Supporting: Provides stable support for high-speed equipment, preventing vibration.

These functions are used in almost every industry, making EPDM rubber rollers widely used.

What types of operating conditions are suitable for EPDM rubber rollers?

EPDM rubber rollers perform excellently in the following conditions:

• High-temperature operating environments

• Steam heating systems

• Hot water contact

• Strong UV environments

• Outdoor equipment

• Acid and alkali solution contact

• Dryers, drying lines

• High humidity workplaces

If the operating temperature, humidity, or chemical environment of the equipment is complex, EPDM rubber rollers are generally more stable than NBR, CR, and NR.

What applications cannot EPDM rubber rollers be used for?

Although EPDM rubber has strong properties, it is not a universal solution.

The following operating conditions are unsuitable for using EPDM rubber rollers:

• Oily environments (especially mineral oils)

• Contact with fuel oils, lubricating oils, or gasoline

• Strong solvent environments (such as ketones and aromatic hydrocarbons)

These environments will cause EPDM to swell or degrade in performance.

What are the applications of EPDM rubber rollers?

✔ EPDM rubber rollers have a wide range of applications, covering almost all industrial scenarios involving humidity, heat, steam, chemicals, and high temperatures.

EPDM rubber rollers are mainly used in:

• Printing industry

• Paper industry

• Textile industry

• Plastic film processing

• Chemical industry

• Food processing

• Metal handling and coating equipment

• Various drying systems

• Steam equipment

• High humidity or outdoor equipment

Their core value lies in:

• Strong steam resistance

• Stable heat resistance

• Excellent ozone and aging resistance

• Good acid and alkali resistance

• Suitable for long-term use and low maintenance costs

If you are looking for a rubber roller material suitable for high-temperature, steam, or humid environments, EPDM rubber rollers are one of the most worthwhile options.

What capabilities set Jinhang apart in the roller manufacturing industry?

As a trusted roller manufacturer, Jinhang integrates design, machining, grinding, coating, balancing, inspection, and after-sales service under one roof. Our team of 60+ technicians uses advanced lathes, boring machines, vertical mills, automatic sand-blasting units, and polyurethane pouring machines to produce high-precision rollers tailored to your machinery.

From standard rubber rollers to complex mirror rolls and ceramic anilox rolls, we ensure high performance, long lifespan, and full compliance with industrial standards.