What are the differences between industrial mirror rollers and embossed rollers?

In industrial manufacturing, roller components are indispensable core parts of continuous production systems. Among them, mirror rollers and embossed rollers are two types of industrial rollers that differ significantly in structure, surface finish, and processing functions.

Although both belong to the industrial roller system, they serve completely different technological purposes in practical applications.

Many people, when first encountering industrial rollers, easily mistake the difference between mirror rollers and embossed rollers for simply whether or not there is a pattern on the surface. However, from the perspective of manufacturing logic and process control, the differences between mirror rollers and embossed rollers go far beyond this.

To truly understand the differences between industrial mirror rollers and embossed rollers, a systematic analysis is needed from multiple levels, including functional positioning, surface structure, contact mechanism, process objectives, and quality impact.

What is a mirror roller? What is its core role in industrial manufacturing?

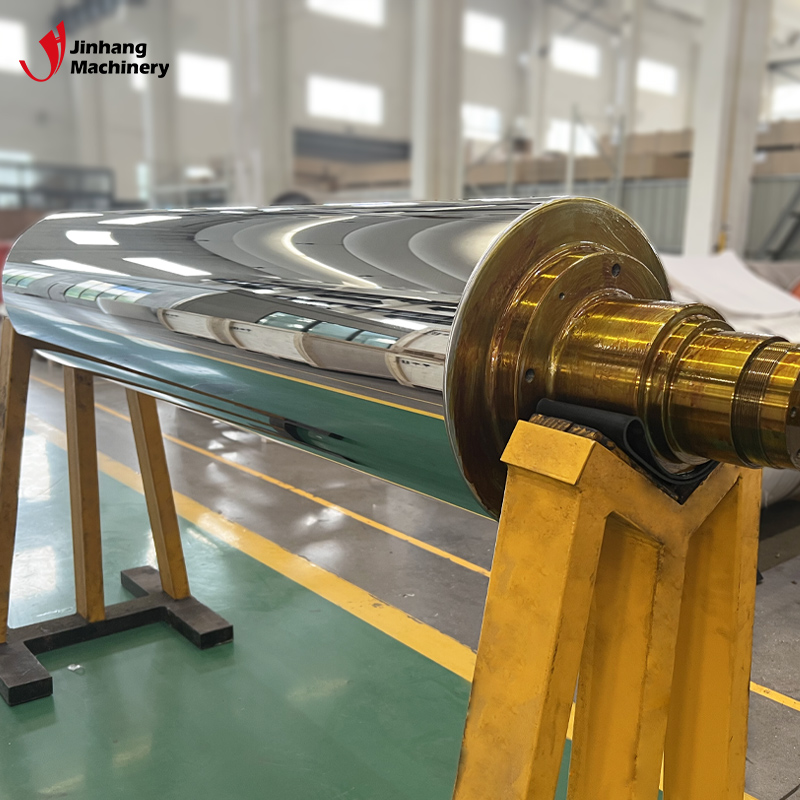

A mirror roller refers to an industrial roller whose surface has undergone high-precision machining and polishing, resulting in extremely low surface roughness. Its surface finish typically exhibits a highly glossy, near-mirror-like reflective effect, hence the name mirror roller.

In industrial manufacturing, the core functions of mirror rollers are mainly reflected in the following aspects:

• Providing a highly flat and uniform contact surface

• Controlling the surface appearance quality of materials

• Ensuring the stable operation of materials during processing

• Participating in key processes such as shaping, pressing, and laminating

Mirror rollers emphasize surface consistency and stability; their value lies primarily in flattening, supporting, or shaping materials without altering their surface structure.

What is an embossing roller? What is its functional role in the process?

Unlike mirror rollers, embossing rollers are industrial rollers with specific patterns, textures, or structures on their surfaces. These patterns are not random but precisely designed and processed to create the desired structural effect on the material surface.

The main functions of embossing rollers in industrial manufacturing include:

• Pressing regular or irregular textures onto the material surface

• Changing the surface morphology and tactile feel of materials

• Adjusting the functional properties of the material surface

• Achieving structural processing rather than merely surface support

Essentially, an embossing roller is a tool that actively alters the surface structure of a material, rather than a simple support or shaping component.

What is the fundamental difference between mirror rollers and embossing rollers?

From the core manufacturing logic, the fundamental difference between mirror rollers and embossing rollers lies in whether they actively alter the surface structure of the material.

1. Mirror Rollers:

• Aim to maintain the original state of the material surface.

• Minimize the presence of structural marks on the surface.

• Emphasize smoothness, cleanliness, and consistency.

2. Embossing Rollers:

• Aim to alter the surface structure under controlled conditions.

• Shape the material through patterns.

• Emphasize the accuracy and stability of texture replication.

This difference in objectives determines the comprehensive differences in the design, manufacturing, and use of mirror rollers and embossing rollers.

What are the differences in surface structure between mirror rollers and embossing rollers?

From the perspective of surface structure, mirror rollers and embossing rollers exhibit completely opposite characteristics.

The surface characteristics of mirror rollers include:

• Extremely low surface roughness

• Continuous, uniform microstructure

• Minimize local unevenness

While embossing rollers have the following surface features:

• Clearly controllable uneven structure

• Regular or specifically designed patterns

• Defined structural depth and contour

This difference in surface structure directly determines their interaction mechanisms during material contact.

What are the differences in the contact mechanisms between mirror rollers and embossing rollers?

In industrial processing, the contact state between materials and industrial rollers is crucial. Understanding the differences in the contact mechanisms between mirror rollers and embossing rollers is key to understanding their distinction.

Mirror rollers typically exhibit:

• Surface contact or near-surface contact

• Relatively uniform contact pressure distribution

• A stronger emphasis on "support and guidance" for the material

Embossing rollers, on the other hand, exhibit:

• Primarily point or line contact

• Significant local pressure concentration

• Texture transfer achieved through pressure concentration

Therefore, mirror rollers emphasize "uniformity," while embossing rollers rely on "difference."

Do mirror rollers have higher surface quality requirements than embossing rollers?

From a processing perspective, mirror rollers typically have more stringent surface quality requirements. Any minute scratches, impurities, or unevenness will be completely replicated on the material surface.

The surface quality requirements for mirror rollers are mainly reflected in:

• Extremely high processing precision

• Strict surface integrity

• Stable microstructure consistency

In contrast, embossing rollers focus more on:

• Accuracy of pattern structure

• Consistency of depth and contour

• Stability of pattern repeatability

This indicates that the difference between mirror rollers and embossing rollers is not a matter of "which is more precise," but rather "different directions of precision."

What are the differences in the pressure application methods between mirror rollers and embossing rollers?

During the process, industrial rollers often require the application of a certain amount of pressure. The difference in the pressure application methods between mirror rollers and embossing rollers directly affects the processing results.

The pressure characteristics of mirror rollers are:

• Uniform pressure distribution

• Primarily used to stabilize material shape

• Prevent excessive local deformation

The pressure characteristics of embossing rollers are:

• Pressure concentrated on the raised areas of the pattern

• Utilizing high local pressure to achieve shaping

• Causing structural changes to the material

This difference in pressure logic leads to mirror rollers and embossing rollers often playing completely different roles in the same production line.

Why do mirror rollers emphasize "stability," while embossing rollers emphasize "consistency"?

During operation, even the slightest fluctuation in a mirror roller directly affects the surface quality of the material. Therefore, mirror rollers emphasize:

• Smooth rotation

• Long-term surface stability

• Controllability under changing operating conditions

Embossing rollers, whose core task is to replicate patterns, focus on:

• Pattern consistency across the entire roller surface

• Structural stability during repeated processing

• Integrity of pattern transfer

This is why mirror rollers and embossing rollers follow different technical logics in their design and manufacturing stages.

What are the differences in process objectives between mirror rollers and embossing rollers?

From a process objective perspective, the differences between mirror rollers and embossing rollers are particularly pronounced.

The process objectives of mirror rollers are typically:

• Maintaining or improving the flatness of the material surface

• Controlling surface finish

• Avoiding the generation of additional textures

The process objectives of embossing rollers, on the other hand, are:

• Forming controllable textures on the material surface

• Changing the surface structure

• Achieving specific functional effects

Therefore, mirror rollers aim for "seamlessness," while embossing rollers aim for "form."

How do mirror rollers and embossing rollers affect product consistency differently?

In continuous production, the condition of industrial rollers often has a magnified effect on product consistency.

If a mirror roller malfunctions, it may lead to:

• Overall fluctuations in surface quality

• Inconsistent smoothness

• Continuous replication of flatness deviations

While deviations in embossing rollers may manifest as:

• Inconsistent pattern depth

• Decreased structural repeatability

• Systematic differences in surface effects

This again illustrates that although mirror rollers and embossing rollers are both industrial rollers, they affect product quality in drastically different ways.

From a manufacturing perspective, can mirror rollers and embossing rollers be substituted for each other?

From a manufacturing perspective, mirror rollers and embossing rollers are almost not interchangeable. This is because their design intentions and functional goals are completely different.

• Mirror rollers cannot perform the structural replication task of embossing rollers.

• Embossing rollers cannot replace the flatness and smoothness control function of mirror rollers.

Attempting to use one type of roller to perform the function of another often leads to process control failures or substandard quality.