What are the principles of heat transfer in industrial heating rollers?

In modern industrial processing, heating rollers are a crucial heat treatment device, widely used in the production of plastic films, paper, textiles, rubber, metal foils, composite materials, and chemical materials. Whether it's for material heat setting, drying, calendering, thermal lamination, baking, preheating, or thermal stability control during processing, heating rollers play a vital role in heat energy transfer.

To achieve stable, uniform, and controllable heating effects, heating rollers must have a scientifically sound heat transfer structure. The process of heat transfer from the heat source to the roller body, and then from the roller body to the processed material, involves multiple thermodynamic principles, including conduction, convection, radiation, thermal equilibrium control, and temperature gradient management.

So, how exactly is heat transferred in a heating roller?

How does the internal structure ensure stable heat output?

How is heat transferred when the roller surface and the material are in contact?

This article will systematically analyze all the physical mechanisms of heat transfer in industrial heating rollers.

Functions and Heat Transfer Requirements of Heating Rollers in Industry

To understand the principles of heat transfer in heating rollers, it is essential to first understand their role in the production system.

A heating roller typically performs the following tasks:

• Stably transferring heat to the material surface

• Maintaining a uniform roller surface temperature

• Maintaining thermal equilibrium during high-speed operation

• Avoiding local overheating or cold spots

• Providing precise and constant processing temperature

• Ensuring structural stability of the material after heating

To meet these requirements simultaneously, a heating roller must be more than just a "heated cylinder," but a high-performance device with precisely designed and strictly controlled heat transfer paths.

The ability of heating rollers to provide stable thermal energy in complex industrial environments relies entirely on their internal structure and heat transfer principles.

What key mechanisms are involved in the heat transfer principles of heating rollers?

The following are the core physical mechanisms in the heat transfer process:

1. Heat Conduction – The main heat transfer method within the roller body

2. Heat Convection – The way the heating medium flows internally

3. Thermal Radiation – Not negligible under high-temperature conditions

4. Contact Heat Transfer – Between the roller surface and the material

5. Thermal Balance – Ensuring uniform and stable temperature

6. Temperature Gradient Control – Reducing temperature fluctuations

7. Dynamic Heat Transfer – A special phenomenon during roller rotation

The following will provide a detailed analysis of each item.

How does the heat source inside the heating roller transfer heat to the roller body?

This is the first and most important heat transfer link in understanding heating rollers.

Common heat sources inside heating rollers include:

• Thermal oil

• Steam

• Electric heating tubes

• Resistance wire heating chamber

• Hot water circulation

• High-temperature fluid

Regardless of the method used, the first stage of heat transfer mainly relies on the following two mechanisms:

1. Internal heating medium generates thermal convection

When the internal heat source begins to heat, the heating medium (such as thermal oil or steam) forms a strong convective circulation. This convection has two main functions:

• To quickly and uniformly distribute the temperature of the internal heat source

• To improve the heat transfer efficiency at the contact point with the roller wall

The speed and direction of convection are related to the internal structure design, for example:

• Spiral flow channel

• Central outflow, return flow at both ends

• Double-layer jacket

• Channel-type circulation

• High-velocity spray structure

These structural designs determine whether the heating roller has a uniform temperature distribution.

2. The roller body wall absorbs heat through heat conduction

After the convective medium contacts the roller wall, heat is transferred from the medium to the inside of the metal wall through heat conduction.

This is the most stable and controllable part of the heat transfer process.

Factors affecting heat transfer efficiency include:

• Roller body material (such as stainless steel, alloy steel)

• Roller wall thickness

• Temperature difference

• Metal crystal structure

For example, although the thermal conductivity of a stainless steel heating roller is weaker than that of copper, its structural strength is higher and its thermal stability is better, making it more reliable in engineering applications.

How does heat diffuse outwards from the inside of the heating roller body?

Once heat enters the roller wall, the next step is to conduct it outwards to the surface of the heating roller.

1. Heat conduction within the metal (Conduction)

This is a purely solid heat conduction process.

The inside of the roller body is usually at a higher temperature, and the temperature decreases outwards according to a certain pattern, forming a temperature gradient.

Heat conduction within the metal follows Fourier's Law:

Heat moves from the high-temperature area to the low-temperature area, and the transfer rate is directly proportional to the temperature difference and thermal conductivity.

Heating roller design must ensure:

• Uniform roller body material

• No material interlayers

• No welding defects

• No pores or blowholes

Otherwise, it will lead to phenomena such as "hot spots" and "cold spots".

2. Maintaining thermal equilibrium when heat diffuses from the high-temperature interior to the roller surface

The heating roller must ensure:

• Stable roller surface temperature

• The temperature difference across the entire roller surface is as small as possible (±1℃~±3℃)

• The roller body does not deform due to temperature differences

Therefore, in the design:

• The internal flow channels must be uniform

• The roller wall thickness must be precise

• The heating structures at both ends must be symmetrical

• Dynamic thermal equilibrium must be maintained during rotation

This is the core technology of high-end heating roller manufacturing.

How is heat transferred between the roller surface and the material?

Once the roller surface reaches the specified temperature, heat must be transferred from the roller surface to the contacting material.

This part is the most critical segment of heat transfer in the heating roller because it determines:

• Whether the material is heated uniformly

• Whether the material deformation is stable

• Whether the calendering or forming quality is reliable

Heat transfer from the roller surface to the material mainly involves three methods:

1. Contact Heat Transfer – the most important method

When the material is pressed directly against the roller surface, heat is transferred through the contact interface. Key factors affecting efficiency:

• Contact area

• Contact pressure

• Roller surface roughness (typically mirror-finish grade, RA 0.01–0.1)

• Material thermal conductivity

• Contact time (affected by heating roller speed)

Therefore, the design must ensure:

• Flat roller surface

• Uniform pressure

• Sufficient contact

• Matching speed and temperature

Contact heat transfer usually accounts for 75%–90% of the total heat transfer.

2. Heat Conduction – Thermal diffusion within the material

After heat is transferred from the interface into the material, secondary conduction occurs internally.

Influencing factors:

• Material thickness

• Material thermal conductivity

• Heating roller set temperature

This determines the processing performance of the material, such as shaping in plastic processing or moisture evaporation in paper.

3. Thermal Radiation – A factor that cannot be ignored in high-temperature rollers

When the heating roller temperature exceeds 150–200℃, the roller body begins to radiate heat to the surrounding environment.

Radiation has less impact on the contact material than contact heat transfer, but in high-temperature rollers:

• Radiation accelerates surface heating

• Preheats the material surface before contact

• Increases the overall thermal effect

However, radiation is uncontrollable and therefore cannot be used as the primary heating method.

Why must high-quality heating rollers maintain uniform temperature?

Temperature uniformity is one of the most important performance characteristics of heating rollers.

If there are temperature differences on the roller surface, it will lead to:

• Uneven heating of the material

• Inconsistent calendering thickness

• Asymmetrical deformation

• Warping of paper or film

• Local embrittlement or excessive softening

• Even product defects

To achieve high temperature uniformity, heating rollers must control:

• Internal flow channel distribution

• Consistent roller wall thickness

• Precise adjustment of the heating system

• High precision of roller surface processing

High-end heating rollers can control temperature differences to:

• ±1℃ (high precision)

• ±3℃ (industrial grade)

This relies on complex thermal design and processing technology.

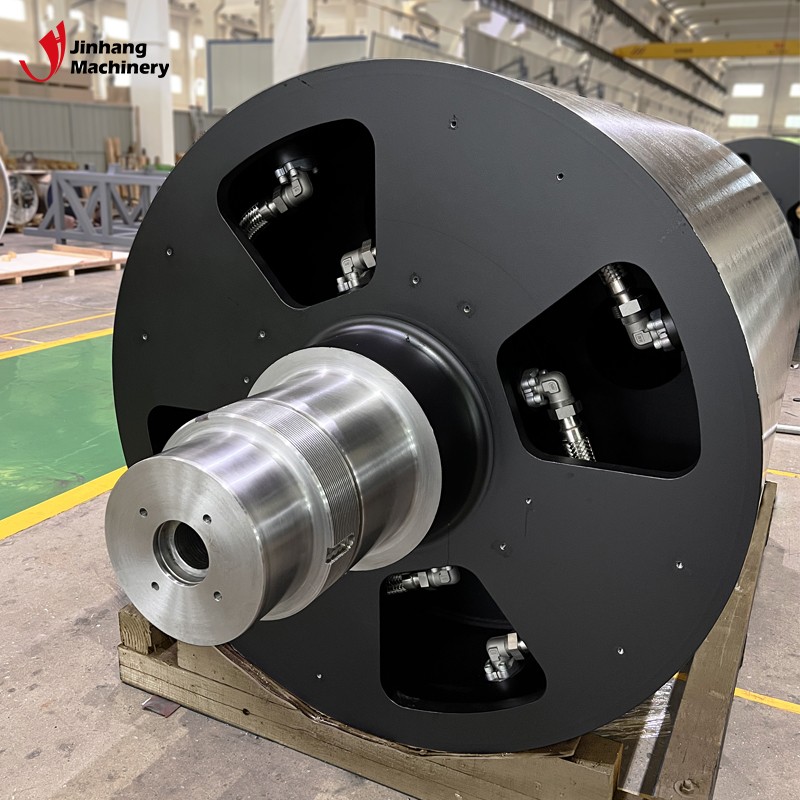

What role does the internal structure of the heating roller play in heat transfer?

The internal structure design of the heating roller directly determines the efficiency of heat transfer. Common structures include:

1. Jacketed Heating Structure

The roller body has a large annular cavity inside.

→ Heat transfer medium circulates

→ Uniform heating of the roller wall

2. Flow Channel Heating Structure

Internal spiral flow channels

→ Heat transfer medium flows uniformly along the path

→ Increased heat exchange area

3. Semi-Jacketed + Central Flow Channel Hybrid Structure

Used in applications requiring extremely high temperature uniformity

→ Highest temperature uniformity performance

4. Electric Heating Tube Structure

Heating the roller body through electric heating tubes

→ Fast response

→ Precise temperature control

Different structures determine the speed, uniformity, and efficiency of heat transfer.

What changes occur in heat transfer when the heating roller rotates?

The heating roller is a moving device, so rotation affects heat transfer:

1. Contact time changes with speed

Higher rotation speed → shorter contact time → reduced heat absorption by the material

Therefore, the rotation speed must match the heating temperature.

2. Rotational centrifugal thermal equilibrium

High-speed rotation helps to distribute heat evenly on the roller wall, but it can also lead to:

• Edge temperature differences

• Increased tendency for roller body deformation

Therefore, heating rollers usually require dynamic balancing calibration.

3. More stable surface temperature

Rotation can continuously transfer local hot spots on the surface to cooler areas, homogenizing the temperature.

Why do heating rollers need to use high thermal conductivity materials?

The material selection of the heating roller directly affects:

• Heat storage capacity

• Temperature response speed

• Heat transfer efficiency

• Processing stability

Common heating roller materials:

• Stainless steel

• Alloy steel

• Coated steel

• Steel roller body with nickel or chromium plating

High-end heating rollers even use ceramic coatings to improve thermal conductivity and wear resistance.

The material determines the heat transfer speed and stability of the roller body.

The Heat Transfer In a Heating Roller Is a Complete Thermal System

The heat transfer process in industrial heating rollers is not a single mechanism, but rather a combination of the following:

1. Internal heat convection through media circulation

2. Heat conduction through the metal roller wall

3. Contact heat transfer from the roller surface to the material

4. Partial thermal radiation under high-temperature conditions

5. Dynamic thermal equilibrium formed during roller rotation

6. Temperature uniformity maintained through internal structural design

7. Enhanced thermal diffusion capability through material selection

In short:

A heating roller is a sophisticated "heat transfer engineering system," whose heat transfer follows the three major thermodynamic principles of conduction, convection, and radiation, and achieves efficient, uniform, and stable heating performance through structural design.

What advantages do your polyurethane rollers have?

As a specialized polyurethane roller manufacturer, we utilize automated polyurethane casting lines to ensure uniform coating thickness, outstanding adhesion, and long service life. PU rollers manufactured by Jinhang Machinery feature exceptional cut resistance, solvent resistance, and resilience, making them ideal for packaging, lithium battery electrode processing, labeling, automotive test benches, and tension control systems. Our grinding process ensures each PU roller meets strict dimensional precision and surface requirements.