Why Use Industrial Mirror Surface Rollers for Surface Correction?

In modern industrial manufacturing, surface correction is an indispensable and crucial step in numerous material forming, precision machining, film calendering, and coating processes. To achieve flatness, smoothness, consistency, and stability of object surfaces, industrial mirror surface rollers have become one of the key pieces of equipment.

With their high precision, high surface finish, high stability, and excellent physical properties, mirror surface rollers play a core role in fields such as plastic film, metal foil, optical film, paper processing, rubber calendering, and coating processes.

However, many users, equipment procurement personnel, or production managers may ask: Since there are various roller devices available for surface correction, why does the industry widely use industrial mirror surface rollers for this purpose? What key problems do mirror surface rollers solve? What is their deeper significance for product performance?

This article will address these questions, providing an in-depth analysis of the reasons for using industrial mirror surface rollers for surface correction, comprehensively explaining it from multiple dimensions, including physical principles, process logic, performance requirements, and material characteristics.

What is an industrial mirror surface roller?

What are the differences between it and ordinary rollers?

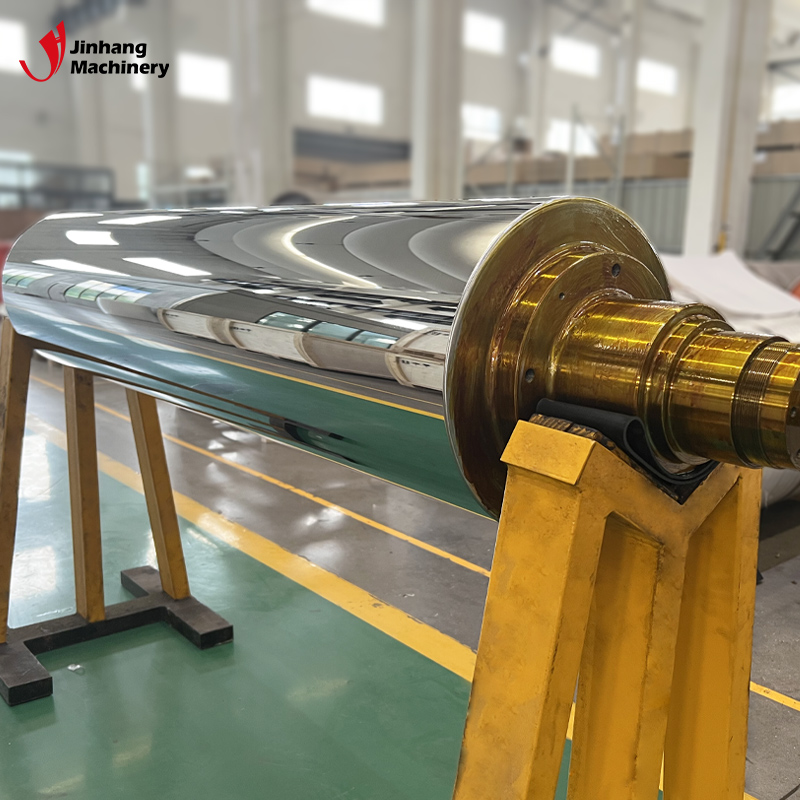

An industrial mirror surface roller is a roller whose surface has been precisely polished, possessing extremely high flatness and brightness. Its surface roughness typically reaches:

Ra 0.005~0.01 μm

or even lower, nanoscale surface finish

The biggest differences between mirror surface rollers and ordinary rollers are:

1. Extremely low surface roughness, with almost no visible texture

This allows the mirror surface roller to replicate its high surface finish and flatness onto the object's surface during calendering or contact with the material.

2. Highly uniform surface morphology

The surface of the mirror surface roller does not have tiny pits, ripples, scratches, or uneven material distribution, thus enabling stable surface correction.

3. High hardness and high wear resistance

This allows the mirror surface roller to maintain a high-precision surface for a long time without rapid deterioration due to processing friction.

4. Ability to maintain stable working performance in high-speed, constant-pressure environments

Mirror surface rollers are usually used in high-speed production lines, and their surface geometric accuracy must maintain extremely high consistency. Based on these characteristics, mirror rollers are widely used in the industry for surface correction.

Why do object surfaces develop problems during the manufacturing process that require correction by mirror rollers?

During material production, whether through extrusion molding, calendering, thermal lamination, coating, casting, or compounding, the following problems can occur on the object's surface:

• Surface roughness or unevenness

• Local unevenness

• Thickness deviations

• Random surface textures

• Ripples or wrinkles due to unstable tension

• Uneven surface shrinkage due to cooling methods

• Micro-defects caused by adhesion and friction

These problems are inherent and cannot be completely avoided by simply adjusting mechanical parameters.

Therefore, secondary or multiple corrections by industrial mirror rollers are necessary to achieve the final surface quality of the material.

Why can mirror rollers achieve surface correction? What is the principle?

Principle 1: Mirror rollers achieve surface flattening through contact replication

The surface of the mirror roller is polished to extremely high precision. When the material is calendered between the mirror roller and a pressure roller or other rollers, its surface "replicates" the flatness and smoothness of the mirror roller.

This replication effect causes the object's surface to have:

• High points flattened

• Low points compensated by internal material tension

• Irregular textures smoothed

Thus completing surface correction.

Principle 2: The geometric precision of the mirror roller surface promotes material flow redistribution

In a hot or semi-fluid state, when the material contacts the mirror roller, the surface molecules rearrange under force, achieving:

• Increased surface density

• Filling of microscopic depressions

• Stable surface structure

This microscopic action makes the material surface more homogeneous.

Principle 3: Mirror rollers can utilize heat for thermal correction

Many mirror rollers have internal temperature control systems. Heat is conducted through the roller wall to the material, achieving:

• The surface of the heat-softened material is easier to flatten

• Temperature equalization reduces stress fluctuations

• Thermal surface correction is more stable than in a cold state

Therefore, the temperature control of the mirror roller is closely related to surface correction.

Why can't ordinary rollers replace mirror rollers for surface correction?

1. Insufficient Surface Roughness of Ordinary Rollers

The surface roughness of ordinary rollers is typically Ra 0.1~0.4 μm, while mirror-finish rollers can achieve Ra 0.005 μm.

The difference in roughness is more than an order of magnitude, resulting in completely different correction effects.

2. Ordinary Rollers Cannot Eliminate the Transfer of Processing Textures

Ordinary rollers themselves have textures, which are transferred to the material during the calendering process, causing undesirable appearance or performance degradation.

3. Ordinary Rollers Cannot Guarantee Large-Area Surface Flatness

Insufficient surface accuracy means:

• Uneven correction

• Local residual ripples

• Unstable large-area flatness

The high precision of mirror-finish rollers precisely solves this problem.

4. Ordinary Rollers May Generate Vibration or Thermal Deformation During High-Speed Operation

Mirror-finish rollers are usually subjected to dynamic balancing and thermal stability treatment, maintaining accuracy during high-speed operation.

Therefore, ordinary rollers cannot replace the role of mirror-finish rollers in surface correction.

What are the specific ways in which mirror-finish rollers improve material surface quality during the correction process?

1. Improved Surface Smoothness

Mirror-finish rollers can polish the material surface to a high gloss, achieving a mirror-like effect.

2. Improved Surface Flatness

Mirror-finish rollers apply uniform pressure to the material, improving surface unevenness and eliminating bumps and depressions.

3. Enhanced Surface Density

After contact with the mirror-finish roller, the surface molecules of the material are more tightly arranged, making the material more wear-resistant.

4. Elimination of Surface Ripples and Wrinkles

Especially in the field of film production, mirror-finish rollers are effective in removing tension ripples.

5. Stable Surface Thickness

Mirror-finish rollers prevent local thickness fluctuations caused by uneven material flow.

6. Improved Material Appearance Consistency

From lateral reflectivity to surface texture uniformity, everything is improved.

Why is temperature control so crucial when using mirror-finish rollers for surface correction?

Mirror-finish rollers are often linked to a temperature control system, requiring precise control of the surface temperature depending on the processing material.

Its importance is reflected in:

1. Hot materials are easier to correct

Heat softens the material surface, facilitating shape adjustment. 2. Uniform Temperature Prevents Surface Deformation

If the temperature is unstable, it will lead to:

• Uneven surface shrinkage

• Morphological distortion

• Reduced correction quality

3. Temperature Accuracy Affects Optical-Grade Mirror Surface Effects

Especially in optical films and electronic materials, temperature errors directly affect surface smoothness.

4. Internal Temperature Control Reduces Thermal Deformation

The mirror roller reduces its own thermal expansion and contraction through internal circulation, ensuring accuracy.

Therefore, temperature control is an important component of mirror roller correction technology.

Why are mirror rollers particularly important for thin films, metal foils, and optical materials?

Because the application scenarios of these materials have extremely strict surface requirements, including:

• Transparency

• Optical reflection performance

• Thickness uniformity

• Surface microstructure stability

• Appearance quality

• Functional layer adhesion effect

Once the surface is uneven, it will lead to:

• Abnormal light scattering

• Uneven coating

• Local performance degradation

• Electrical performance attenuation

• Reduced appearance grade

The mirror roller, as the core equipment for surface correction, solves all these problems.

Does the surface correction of objects by mirror rollers affect the mechanical properties of the material?

1. Mirror rollers do not damage the material structure

Correction is performed under non-destructive pressure and does not affect the base structure of the material.

2. Mirror rollers can improve surface stress distribution

The flattened material is less prone to cracking during subsequent use.

3. Surface densification improves wear resistance

The service life of many materials is thus increased.

4. The correction process does not change the internal composition of the material

The mirror roller only acts on the surface micro-layer and does not change the material body.

Therefore, mirror rollers not only do not affect mechanical properties, but sometimes even make the material more stable.

What are the process advantages of using mirror rollers for surface correction?

1. High process reproducibility

Mirror roller processing is stable and can maintain consistent correction results for a long time.

2. Strong applicability to different materials

Including plastics, rubber, metal foils, fiber materials, etc.

3. Suitable for high-speed production

Accuracy and stability allow mirror rollers to be used in automated production lines.

4. Does not produce secondary surface defects

Mirror rollers do not cause additional textures or indentations, making them an ideal correction tool. 5. Low Equipment Maintenance Costs

Compared to complex mechanical adjustments, mirror roller calibration is more efficient.

Industrial Mirror Rollers Are Key Core Equipment for Achieving High-Quality Surface Correction

Using industrial mirror surface rollers to correct the surface of objects is one of the most reliable, stable, and precise surface treatment methods in modern manufacturing.

This is because:

• Mirror rollers achieve a replication effect through their high-gloss surface.

• They can precisely control the surface morphology of the material.

• They can eliminate surface defects, ripples, and textures.

• They have temperature control capabilities to improve correction stability.

• They are suitable for large-area, high-speed, and high-precision manufacturing scenarios.

Whether it's films, metal foils, optical materials, or coated products, mirror rollers play a crucial role in surface correction, and are core technical equipment for ensuring the final quality of the product.

Do you produce temperature-controlled rollers?

Yes. As an experienced heating roller manufacturer, we design and build rollers with internal heating channels or oil circulation systems. These rollers deliver uniform temperature distribution across the entire surface, crucial for coating, calendering, laminating, and thermal compression processes. We perform pressure testing, welding inspections, and surface finishing to guarantee safe, stable, and long-term operation under high-temperature conditions.