What Surface Treatment Methods Do Roller Manufacturers Offer?

In industrial production equipment, various industrial rollers perform core tasks such as traction, pressing, coating, guiding, cooling, heating, and surface treatment. The performance of industrial rollers is largely determined by their surface treatment method. Different process requirements, material types, friction conditions, temperature environments, and corrosion resistance characteristics all necessitate the selection of different industrial roller surface treatment processes.

For buyers, equipment manufacturers, and technical engineers, understanding the surface treatment methods offered by roller manufacturers can not only help in selecting the appropriate roller type but also help optimize production line performance, extend service life, and improve product quality.

As a high-quality industrial roller manufacturer, Jinhang Machinery can provide users with complete surface treatment solutions based on different working conditions, equipment needs, and material characteristics.

This article will delve into common surface treatment methods offered by roller manufacturers, their technical characteristics, applicable industries, and process differences, helping you gain a comprehensive understanding of the industrial roller surface treatment system.

Why is Surface Treatment Necessary for Industrial Rollers?

In the industrial roller manufacturing process, surface treatment is a crucial step in determining whether the roller can be successfully applied to specific working conditions. The main reasons include:

(1) Improving Wear Resistance

Under high-speed and high-pressure conditions, the roller body will experience friction with the material, and untreated metal surfaces may wear down quickly.

(2) Enhancing Corrosion Resistance

Some production processes involve environments with high acidity, alkalinity, solvents, and humidity, where ordinary metals are prone to corrosion, affecting their service life.

(3) Improving Surface Finish

For example, mirror rollers require polishing and plating processes to achieve high surface finish requirements for thin films or sheet materials.

(4) Improving Conductive or Insulating Properties

Some processing rollers, such as Corona treatment rollers, require specific electrical properties and must use special coatings.

(5) Enhancing Tension Control Capabilities

Differences in surface roughness directly affect the traction, pressing, and conveying quality of the material.

Therefore, a professional roller manufacturer must be able to provide a variety of surface treatment methods to suit different production scenarios.

What Surface Treatment Methods Do Roller Manufacturers Offer?

Professional roller manufacturers typically possess a variety of surface treatment technologies. Based on Jinhang Machinery's actual manufacturing capabilities, common surface treatment methods can be summarized into the following categories:

(1) Chrome Plating

Chrome plating is one of the most common surface treatments used by roller manufacturers. Its characteristics include:

• High hardness (up to 900-1100 HV)

• Excellent wear resistance

• Good corrosion resistance

• Smooth surface finish

Suitable for: mirror rollers, guide rollers, embossing rollers, bending rollers, etc.

(2) Tungsten Carbide Coating (HVOF, Plasma Spraying)

Tungsten carbide coatings, due to their exceptional hardness (above 1200 HV), are ideal for high-wear applications. Their characteristics include:

• Extremely high wear resistance

• Excellent scratch resistance

• Suitable for high-temperature environments

• Stable surface friction coefficient

Suitable for: high-load extrusion rollers, calendering rollers, Corona treatment rollers, coating rollers, etc.

(3) Rubber Coating

Often used by roller manufacturers for applications requiring elasticity, shock absorption, chemical resistance, or specific friction characteristics. Common rubber types include:

• Nitrile rubber (NBR)

• Polyurethane rubber (PU)

• Silicone rubber

• Neoprene (CR)

• EPDM rubber

Suitable for: printing rollers, laminating rollers, composite rollers, pressure rollers, etc.

(4) Mirror Polishing

Mirror rollers achieve extremely high surface smoothness (usually Ra < 0.01 μm) through multiple stages of grinding and polishing.

Characteristics include:

• Reduced friction

• Improved final appearance of film or sheet materials

• Enhanced heat transfer efficiency

• Prevention of material scratching

Mainly used in the plastic film industry, sheet metal industry, and calendering production lines.

(5) Ceramic Coating

Ceramic coatings offer excellent corrosion resistance and insulation properties, including:

• Chromium oxide

• Aluminum oxide

• Zirconium oxide

Suitable for:

• Chemical production lines

• Highly corrosive working conditions

• Corona treatment rollers

• High-temperature equipment rollers

(6) Chrome-free Special Coatings

Such as:

• Fluoropolymer coatings

• Non-stick coatings

• Special solvent-resistant coatings

These are common processes used by roller manufacturers in specific industries (such as coating, tape, and lithium battery materials).

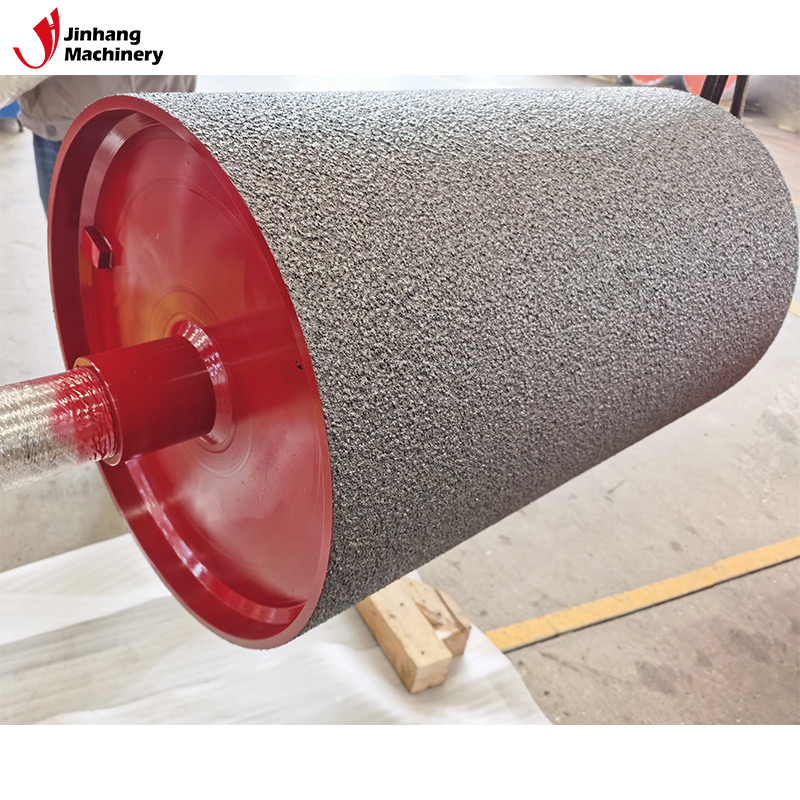

(7) Sandblasting and Surface Roughening Treatment

Some rollers require a specific rough surface to achieve traction effects, for example:

• High-viscosity film traction

• Paper conveying

• Adhesive material manufacturing

Common treatments include:

• Sandblasting

• Electrical discharge machining (EDM)

• Laser engraving

Suitable for guide rollers, traction rollers, gluing rollers, etc.

(8) Conductive or Insulating Coatings for Corona Treatment Rollers

Corona rollers have specific surface requirements, including:

• High-insulation ceramic layer

• Uniform conductive coating

• Arc-resistant coating

This is one of the important indicators of a roller manufacturer's technical capabilities.

How do roller manufacturers generally choose the appropriate surface treatment process?

In the actual manufacturing process, roller manufacturers usually determine which surface treatment to use based on the following factors:

(1) Customer equipment requirements (pressure, speed, temperature)

High-speed extrusion production lines require high wear-resistant coatings; low-speed calendering equipment may prioritize surface finish.

(2) Material characteristics

For example:

• Film industry: requires mirror chrome plating or mirror polishing

• Coating industry: requires non-stick coatings

• Printing industry: requires rubber covering

(3) Corrosive environment

Strong acid, strong alkali, or solvent conditions require the selection of ceramic spraying or special coatings.

(4) Temperature control structure (heating roller or cooling roller)

The coating must not affect the temperature transfer efficiency.

A professional roller manufacturer will combine materials, temperature, speed, load, and industry requirements to design the best surface treatment method for the customer.

Under what circumstances is the chrome plating process most suitable?

Chrome plating is often recommended by roller manufacturers for the following applications:

•When a high surface finish is desired

•When excellent corrosion resistance is required

•When low friction is expected

•When operating temperatures are high

•When an easy-to-clean surface is needed

Typical applications:

•Mirror rollers

•Guide rollers

•Cooling rollers

•Coating equipment

•Calendering equipment

Chrome plating has a wide range of applications and is one of the most versatile high-quality surface treatments offered by roller manufacturers.

Is tungsten carbide coating suitable for high-wear conditions?

The answer is – absolutely.

The main advantages of tungsten carbide coating offered by roller manufacturers are:

•Extremely high hardness

•High scratch resistance

•Long service life

•Suitable for complex environments

•Stable coefficient of friction with contacting materials

Suitable for:

•High-speed film stretching equipment

•High-wear rollers in coating equipment

•Metal processing equipment

•High-temperature production lines

If the strongest wear resistance is required, tungsten carbide coating is the top recommendation from roller manufacturers.

What are the performance characteristics of rubber coating?

Roller manufacturers often provide rubber coating processes to meet the following needs:

•High elasticity

•Good friction

•Chemical resistance

•Good resilience

•Processable to different hardness levels

Rubber rollers are widely used in:

•Printing

•Packaging

•Laminating

•Textiles

•Papermaking

Rubber coating is a common basic service offered by roller manufacturers, but it requires professional casting equipment and curing processes.

What advantages does mirror polishing treatment offer?

Mirror rollers are important key equipment in many industries, and roller manufacturers must ensure during the manufacturing process:

•High precision roundness

•Extremely low surface roughness

•Uniform surface finish

The advantages of mirror polishing include:

•Improved film surface smoothness

•Improved product appearance (plastics, sheets)

•Prevention of material scratching

•Improved heat exchange efficiency

Professional roller manufacturers like Jinhang Machinery are equipped with imported POMINI grinding machines to further ensure mirror quality.

What are the special surface treatment characteristics of Corona treatment rollers?

Corona rollers differ from conventional industrial rollers, requiring specific surface treatments with the following characteristics:

• The surface must not be susceptible to corona discharge damage.

• The material must possess insulating properties.

• It must withstand high-frequency arc discharge.

• The surface must be uniform.

Common coatings include:

• Ceramic coatings

• Special rubber layers

• Special insulating coatings

Roller manufacturers need professional coating equipment to manufacture high-quality Corona treated rollers.

How does industrial roller surface treatment affect working life?

Surface treatment is a critical factor affecting the lifespan of industrial rollers. Its impact includes:

(1) Improved wear resistance, reducing maintenance frequency

Higher hardness leads to longer lifespan.

(2) Enhanced corrosion resistance, preventing premature damage

Especially important for chemical processing environments.

(3) Surface stability affects product quality consistency

Such as coating uniformity and traction stability.

(4) Reduced cleaning frequency, improving overall efficiency

For example, the easy cleaning of chrome-plated rollers.

Therefore, choosing the correct surface treatment method is an important technical service that roller manufacturers must provide.

Why choose Jinhang Machinery for surface treatment?

As a professional Chinese manufacturer of high-quality rollers, Jinhang Machinery has the following advantages in the field of surface treatment:

(1) Comprehensive surface treatment processes

Including:

• Chrome plating

• Tungsten carbide spraying

• Rubber coating

• Mirror polishing

• Ceramic coating

• Special coatings

• Sandblasting and texturing

• Special treatment for Corona rollers

Providing a very complete range of services.

(2) Advanced equipment system

Such as:

• Italian imported POMINI grinding machine

• Automatic sandblasting machine

• Polyurethane casting equipment

• Large lathes and boring machines

• Dynamic balancing machine

Ensuring the stability and consistency of surface treatment.

(3) Customizable according to drawings

Supporting OEM/ODM, meeting the surface specifications required for different production processes.

(4) Professional engineering team

Able to recommend the best surface treatment solution based on industry working conditions.

How to judge whether a roller manufacturer's surface treatment capabilities are professional?

To assess whether a roller manufacturer has excellent surface treatment capabilities, you can evaluate the following aspects:

✔ Do they offer a variety of surface treatment methods?

✔ Do they possess high-precision grinding machines, chrome plating equipment, spraying systems, and polishing equipment? ✔ Do you have casting equipment for rubber coating?

✔ Are you capable of manufacturing heating rollers, cooling rollers, and corona rollers with complex structures?

✔ Can you recommend suitable coatings based on working conditions?

Overall, Jinhang Machinery, with its complete equipment system, extensive surface treatment processes, and strong customization capabilities, possesses the professional expertise expected of a high-level roller manufacturer.