What types of cemented carbide industrial rollers are there?

In modern industrial manufacturing, industrial rollers are widely used in core processes such as rolling, calendering, coating, conveying, shaping, film formation, and stretching. Ordinary steel rollers can no longer meet the stringent production requirements of high strength, high wear resistance, high corrosion resistance, and high-temperature impact resistance in many scenarios. Therefore, more advanced cemented carbide industrial rollers have become key components in high-end production lines.

With their extremely high hardness, excellent wear resistance, corrosion resistance, and stable dimensional accuracy, cemented carbide industrial rollers have become an irreplaceable technological foundation component in many industries. They not only extend equipment lifespan but also significantly reduce downtime for maintenance, improving production stability.

Therefore, many companies ask the same question when building high-end production lines:

"What types of cemented carbide industrial rollers are there?"

This article will systematically analyze the classification and characteristics of cemented carbide industrial rollers from multiple perspectives, including structure, material composition, manufacturing methods, and application characteristics, helping you to fully understand this key component.

Why do industrial production need cemented carbide industrial rollers?

In high-load, high-speed, high-temperature, and highly corrosive environments, traditional steel rollers suffer from:

• Rapid wear

• Surface scratches

• Out-of-roundness

• Cracking

• Surface layer peeling

• Temperature deformation

• Short lifespan and frequent maintenance

These problems directly affect product thickness, surface quality, gloss, flatness, and dimensional stability.

Carbide industrial rollers, on the other hand, offer the following advantages:

• High hardness (up to HRA 88 and above)

• Extremely strong wear resistance

• Good thermal stability

• Less prone to deformation

• Strong corrosion resistance

• Suitable for high-speed and heavy-load conditions

• Significantly extended service life

Therefore, carbide industrial rollers are widely used in high-strength, high-precision applications to ensure efficient and stable production line operation.

What are carbide industrial rollers, and what materials do they consist of?

Carbide industrial rollers are typically composed of carbide particles (such as tungsten carbide WC) + a metal binder (such as cobalt Co).

Key Characteristics:

• Carbide particles: Provides extremely high hardness (second only to diamond)

• Metal binder: Provides toughness and impact resistance

• High density, high modulus: Not easily bent or out of round

Its structure can be divided into:

• Integral cemented carbide rollers

• Surface cemented carbide coating, spraying, or thermal spraying

• Cemented carbide composite structure roller core

Therefore, "cemented carbide industrial rollers" are not the same as "a single piece of cemented carbide," but rather different material combinations are used depending on process requirements.

What are the common types of cemented carbide industrial rollers?

Below is a complete classification of cemented carbide industrial rollers based on their applications, structure, manufacturing methods, and material properties.

What material types are available for cemented carbide industrial rollers?

This is the first question many users want answered, so we created this as our first question-based heading.

What cemented carbide materials can be used to manufacture industrial rollers?

Depending on the carbide material, common cemented carbide industrial rollers include:

1. Tungsten Carbide (WC) Industrial Rollers

• The most common type of cemented carbide

• Extremely high hardness (HRA 87-92)

• Extremely high wear resistance

• Suitable for high pressure, high speed, and heavy loads

2. Titanium Carbide (TiC) Industrial Rollers

• Stronger resistance to high-temperature oxidation

• Suitable for metal rolling

• Often used in combination with other carbides

3. Chromium Carbide (Cr₃C₂) Industrial Rollers

• Excellent corrosion resistance

• Suitable for chemical, acidic environments, and highly corrosive media

• Commonly used with thermal spraying

4. Multiphase Composite Cemented Carbide Industrial Rollers

For example:

• WC–Co–Cr

• WC–Co–Ni

• WC–TiC–Co

These composite cemented carbides combine different properties to improve the overall performance of the industrial rollers.

What are the manufacturing methods for cemented carbide industrial rollers?

What are the manufacturing processes for cemented carbide industrial rolls?

The main types include:

1. Solid Carbide Roll

• The entire roll body is made of sintered cemented carbide.

• High strength, high precision, and long service life.

• Highest cost.

2. Carbide Sleeve Roll

• The roll core is made of steel.

• The outer layer is made of cemented carbide sleeve.

• Balances cost and performance.

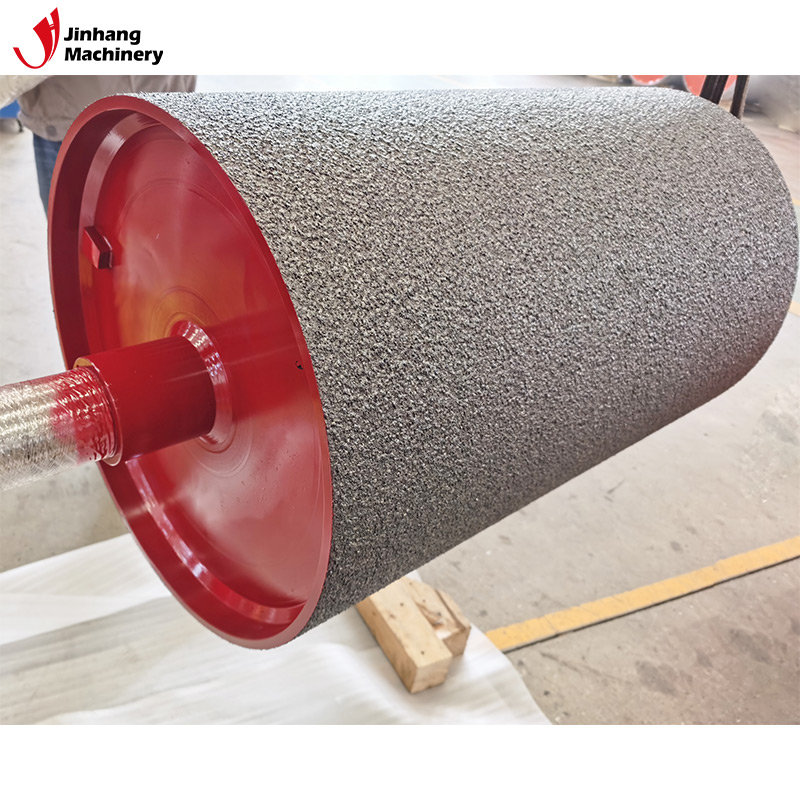

3. Carbide Thermal Spray Roll

Common spraying methods include:

• High-velocity oxygen fuel (HVOF) spraying

• Plasma spraying

Features:

• High surface hardness

• Can reach HV1200~HV1500

• Suitable for processes with high wear resistance requirements but no high load requirements.

4. Carbide Overlay Roll

A cemented carbide overlay layer is formed on the roll surface using welding technology.

Advantages:

• Low cost

• Good wear resistance

• Easy repair

5. Hard Chrome Plated Carbide Reinforced Rolls

Although hard chrome plating is not a carbide material, its extremely high hardness and corrosion resistance often place it under the category of hard surface treatment.

What are the structural classifications of carbide industrial rolls?

What are the differences between different structural forms of carbide industrial rolls?

Based on their internal structure, carbide industrial rolls are classified as:

1. Solid Roll Structure

• Simple structure

• High strength and good bending resistance

• Commonly used in heavy-duty applications

2. Hollow Roll Structure

• Internal flow channels allow for the passage of cooling water or heat transfer oil

• More stable temperature control performance

• Suitable for temperature control equipment such as heating rolls and cooling rolls

3. Roll Core + Carbide Layer Composite Structure

• Combines the strength of steel rolls with the wear resistance of carbide

• High cost-effectiveness

• Wide range of applications

What are some commonly used carbide industrial rolls in different industries?

In industrial manufacturing, which processes utilize different types of carbide industrial rollers?

Carbide industrial rollers can be categorized by application:

1. Calendering Carbide Industrial Rollers

Features:

• High hardness

• High load capacity

• Low deformation resistance

Commonly used in:

• Plastic calendering

• Metal calendering

• Rubber calendering

2. Coating Carbide Industrial Rollers

Features:

• Extremely high surface finish

• Corrosion resistance

• Wear resistance

Suitable for coating machines, gluing machines, and ink coating processes.

3. Rolling Carbide Industrial Rollers

Features:

• High impact resistance

• High strength

• Resistance to thermal fatigue

Used in metal rolling processes, such as rolling copper, aluminum, and stainless steel sheets.

4. Guide Carbide Industrial Rollers

Suitable for high-speed material conveying, such as film production lines.

5. Embossed Carbide Industrial Rolls

Features:

• Extremely high wear resistance

• Stable surface pattern

• Long service life, suitable for mass production

What are the surface treatment options for carbide industrial rolls?

Although carbide itself has high hardness, common treatments to further improve performance include:

• Chrome plating

• Nickel plating

• HVOF coating

• Laser cladding

• Ceramic coating

• Passivation treatment

• Mirror polishing

Different treatment methods correspond to different process requirements, such as wear resistance, corrosion resistance, heat resistance, and friction reduction.

How to determine which type of carbide industrial roll is more suitable for your process?

Selection criteria include:

• Temperature range

• Material hardness

• Pressure load

• Surface finish requirements

• Corrosion resistance required

• High-speed operation

• Heavy-duty rolling involved

• Risk of acid/alkali contact

For example:

• High wear → WC–Co type preferred

• High temperature → TiC or composite cemented carbide preferred

• High corrosion → Cr₃C₂ type or coated structure preferred

• High frequency contact pressure → Integral or high-thickness cemented carbide structure

Common Misconceptions and Correct Understandings About Cemented Carbide Industrial Rolls

Some common misconceptions include:

Misconception 1: The harder the cemented carbide, the better

Fact: Higher hardness → lower toughness → more prone to chipping

The appropriate hardness must be selected according to the load conditions.

Myth 2: Carbide industrial rollers do not require surface treatment

Fact: Surface treatment significantly improves:

• Corrosion resistance

• Scratch resistance

• Surface finish

• Thermal stability

Myth 3: Solid carbide rollers are always superior to composite rollers

Fact: Solid carbide rollers are extremely expensive and have lower toughness; composite structures are actually more suitable for many industries.

Carbide industrial rollers come in a wide variety of types, mainly categorized as follows:

1. By Material

• Tungsten carbide industrial rollers

• Titanium carbide industrial rollers

• Chromium carbide industrial rollers

• Multiphase composite carbide rollers

2. By Structure

• Integral carbide rollers

• Sleeve-type carbide rollers

• Spray-coated carbide rollers

• Weld-overlay carbide rollers

• Coated carbide reinforced rollers

3. By Process Application

• Rolled carbide industrial rollers

• Coated carbide industrial rollers

• Rolled carbide industrial rollers

• Guided carbide industrial rollers

• Embossed carbide industrial rollers

What makes your mirror-finish rollers highly accurate?

As a professional mirror roller manufacturer, we rely on Italian POMINI grinding technology and fine polishing processes to achieve ultra-low surface roughness. These mirror rollers are widely used in film extrusion, optical coating, high-end printing, and battery diaphragm production.

The precision surface provides exceptional flatness and gloss uniformity. We also maintain strict roundness and straightness standards to minimize vibration and enhance product consistency on your production line.