Why do industrial mirror rollers require coating treatment?

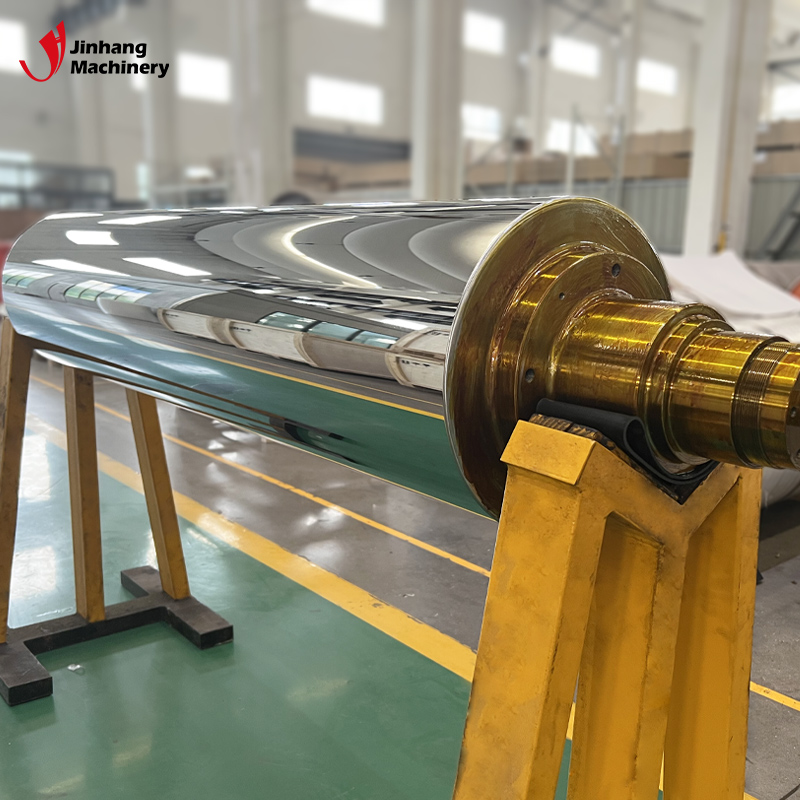

Industrial mirror rollers are key roller types used in industries such as plastic films, metals, paper, and composite materials. Their core function is to ensure high surface smoothness, high gloss, and stable surface tension control.

Throughout the processing, mirror rollers play crucial roles in heat conduction, pressure transmission, surface correction, cooling and shaping, and optical-grade surface replication. Therefore, the manufacturing and processing technology of mirror rollers directly determines the stability of product quality.

In the field of mirror roller manufacturing, "coating treatment" is almost an indispensable key step. From traditional hard chrome plating to the increasingly common tungsten carbide coatings, ceramic coatings, and nitride coatings, different working conditions require different types of surface enhancement methods.

So, why must mirror rollers undergo coating treatment? What problems arise from not coating? What specific properties does coating improve? This article will provide a comprehensive analysis from a professional perspective.

Why can't mirror rollers maintain their performance solely through the hardness of the base material?

In manufacturing industrial mirror rollers, the base material is typically 45# steel, alloy steel, stainless steel, or cast iron. These materials possess good mechanical strength and machinability, but they share a common drawback—their surface physical properties are insufficient to meet the stringent requirements of mirror roller operation. For example:

• Limited inherent hardness;

• Insufficient wear resistance;

• Prone to surface oxidation under high-temperature conditions;

• Prone to scratches with prolonged contact friction;

• Surface micropores easily attract impurities and contaminate products.

If the mirror roller is not coated, the base material alone is insufficient to guarantee its stable operation. Therefore, coating is not merely an additional process, but a crucial prerequisite for the normal use of the mirror roller.

What are the core purposes of mirror roller coating treatment?

Coating treatment provides mirror rollers with a range of enhanced properties, including increased hardness, improved corrosion resistance, enhanced wear resistance, and improved optical effects. The following are some of the most important functions.

1. Significantly Improved Surface Hardness and Wear Resistance

Mirror rollers often operate under conditions including continuous rotation, prolonged contact with materials, and repeated pressure. If the surface is not hard enough, it is prone to:

• Scratches

• Pitting

• Traditional mechanical wear

Hard chrome plating can achieve a surface hardness of HRC 60 or higher for mirror rollers, while tungsten carbide coatings can even exceed 1400 HV. Higher hardness results in more stable mirror finish and better reliability.

2. Improved Corrosion Resistance and Chemical Stability

Many production environments contain moisture, corrosive media, acids, alkalis, or vapors, such as:

• Volatile chemicals from plastic extrusion

• Additives in pulp

• Solvents in coating materials

• Water-based or oil-based chemical raw materials

Uncoated mirror rollers are prone to oxidation or corrosion; therefore, coating effectively protects the base material and extends the workpiece's lifespan.

3. Enhancing Mirror Replication Capability and Surface Optical Quality

The key to the gloss and high mirror effect imparted by mirror rollers lies in their surface geometric precision and microscopic flatness. Coatings can achieve a true "mirror-level" reflective effect by:

• Improving surface density

• Reducing the number of micropores

• Filling microscopic surface defects

4. Maintaining Long-Term Stable Thermal Conductivity

Some coatings, such as hard chrome or nitrides, can provide a protective layer while maintaining high thermal conductivity, allowing the mirror roller to maintain stable performance during heating and cooling.

What are some common surface coating options for mirror surface rollers?

Industrial mirror rollers can be coated with different coatings depending on the application conditions. Each coating has its own characteristics and applicable scope.

1. Hard Chrome Plating

Hard chrome plating is the most widely used coating in the mirror roller industry, possessing the following characteristics:

• High hardness

• Good abrasion resistance

• Good corrosion resistance

• Moderate cost

• High mirror gloss

The disadvantage of hard chrome is its relatively high brittleness; therefore, careful control of the coating structure is necessary in heavy-load or impact environments.

2. Tungsten Carbide Coating (WC)

Made using HVOF (High-Speed Oxygen-Fuel Spraying) technology, its advantages include:

• Very high hardness

• Extremely high abrasion resistance

• Good corrosion resistance

• Suitable for high-pressure, high-temperature environments

Suitable for mirror rollers requiring extremely high abrasion resistance.

3. Ceramic Coating

Ceramic coatings possess the following characteristics:

• High chemical stability

• Extremely strong corrosion and acid resistance

• Low coefficient of thermal expansion

• Suitable for humid corrosive environments

Widely used in industries with high requirements for chemical performance.

4. Nitride Coating

Ceramic nitriding surface treatment offers:

• High corrosion resistance

• Good wear resistance

• Advantages in high-frequency friction environments

Suitable for mirror rollers operating at high speeds for extended periods.

What problems arise from not coating mirror rollers?

If mirror rollers are not coated, their service life, surface quality, and stability will be severely affected. Common problems include:

1. Surface scratches leading to decreased mirror quality

Once scratches appear on the surface of the mirror roller, the mirror replication capability cannot be guaranteed, directly reducing the product's appearance quality.

2. Prone to oxidation or corrosion

Exposure of the base material to air, water vapor, or chemicals accelerates oxidation, causing the mirror surface to darken.

3. Unstable mirror gloss

Uncoated surfaces are more prone to gloss loss due to micropores and processing textures.

4. Increased maintenance frequency

Mirror rollers without coating protection require frequent polishing or even return for repair, increasing costs.

Why does the coating on mirror rollers extend their service life?

The extended service life comes from the combined effects of the coating in several aspects:

• Improved wear resistance, reducing mechanical wear

• Enhanced corrosion resistance, reducing oxidation risk

• Prevention of surface damage caused by material adhesion

• Increased tolerance to working environments

• Reduced maintenance frequency

Mirror rollers require high-speed, high-pressure, and long-term operation in many industries, and the coating provides crucial protection.

Does the coating treatment on mirror rollers guarantee the stability of material processing?

The answer is yes. The coating makes the surface properties of mirror rollers more controllable, especially when processing:

• Plastic films

• BOPP/PET films

• Aluminum foil

• Paper

• Coating materials

• Optical-grade films

During the process, the coating ensures:

• High consistency in material-roller surface contact

• More uniform surface heat conduction

• More stable pressure distribution

• Maintained mirror precision over a long period

These factors collectively determine the physical properties and appearance quality of the final product.

Does the coating on mirror rollers affect subsequent rough and fine polishing processes?

There is a close relationship between the coating and polishing processes. After coating, the surface of the mirror roller requires rough polishing, fine polishing, and even ultra-fine polishing to achieve an optical-grade mirror finish.

The coated surface provides a denser and more stable processing platform, thereby:

• Improving the smoothness after polishing

• Reducing polishing time

• Reducing the heat-affected zone during polishing

• Enhancing the overall mirror finish grade of the mirror roller

Therefore, the coating not only does not affect polishing but also improves its final effect.

How does the coating help mirror rollers maintain higher cleanliness?

Mirror rollers come into contact with various materials during production, such as resins, inks, adhesives, and additives. If the roller surface has micropores, rough spots, or defects, these substances can easily adhere to or remain, leading to surface contamination.

The density of the coating can:

• Reduce micropore adsorption

• Reduce material residue

• Make the roller surface easier to clean

• Reduce contamination caused by surface defects

This is particularly critical for the plastic film and optical film industries.

Will the coating process affect the balance and dynamic performance of the mirror roller?

No. A high-quality coating with uniform thickness, after subsequent finishing and dynamic balancing, can maintain the mirror roller's:

• Dynamic balance performance

• Weight consistency

• Rotational stability

This is one of the key reasons why industrial mirror roller coating technology is highly mature.

What impact does the mirror roller coating have on its thermal stability?

Thermal stability is a crucial indicator of mirror roller performance. The coating's functions include:

• Preventing surface oxidation at high temperatures

• Maintaining stable heat conduction

• Preventing thermal expansion and contraction from affecting the surface structure

• Not weakening the mirror roller's cooling efficiency

For example, hard chrome and tungsten carbide coatings maintain physical stability at high temperatures, allowing the mirror roller to perform well in heat setting, extrusion, and calendering processes.

Can the mirror roller coating improve surface friction characteristics?

The coefficient of friction on the surface of a mirror surface roller directly affects:

• Material flattening

• Tension control

• Surface smoothness

• Contact heat transfer

Coatings can adjust frictional characteristics as needed, for example:

• Hard chrome reduces adhesion

• Tungsten carbide improves scratch resistance

• Ceramic reduces material adhesion

This allows mirror surface rollers to adapt to different production processes.

Coatings Are the Core Guarantee of the Performance of Industrial Mirror Surface Rollers

Whether in terms of wear resistance, corrosion resistance, mirror quality, material stability, thermal properties, or long-term service life, coatings play an irreplaceable role. The core reason why industrial mirror surface rollers have become key components in modern material processing equipment lies in the enhanced capabilities provided by coating technology.

Without coatings, mirror surface rollers cannot complete the demanding tasks in industrial production; with coatings, mirror surface rollers can truly achieve high-precision, high-stability, and long-life surface treatment capabilities.

Can you manufacture chill rollers for cooling applications?

Absolutely. As a reliable chill roller manufacturer, Jinhang Machinery designs cooling rollers with optimized internal water channels to ensure rapid heat transfer and stable temperature control. These rollers are used in sheet extrusion, film casting, calendering, and coating lines.

Our production includes high-precision grinding, pressure testing, corrosion-resistant surface treatments, and dynamic balancing to guarantee smooth and efficient operation in cooling-dominant processes.