What Is The Typical Lead Time For Industrial Roller Manufacturers?

When purchasing industrial rollers, "lead time" is a key concern for almost all customers. Whether it's for new equipment installation, replacing old rollers, or production line maintenance, the delivery time of industrial rollers directly impacts production schedules, inventory management, and equipment downtime risks.

However, many customers find significant differences in lead times offered by different roller manufacturers when inquiring about prices: some offer only a few weeks, while others require two to three months, or even longer.

So the question arises:

What is the typical lead time for industrial roller manufacturers?

Why is there such a large difference in lead times offered by different roller manufacturers for the same product?

What factors truly determine a roller manufacturer's delivery cycle?

This article will systematically analyze the lead time issue of industrial roller manufacturers from multiple dimensions, including the manufacturing process, customization complexity, manufacturing capabilities, and quality control, helping you establish clear and rational judgment criteria.

Why is it difficult to achieve a "standard lead time" for industrial rollers?

Unlike standardized parts, industrial rollers almost never have completely uniform specifications. Even within the same industry, industrial rollers can vary significantly in the following aspects:

• Roller diameter and length

• Operating temperature

• Speed requirements

• Surface treatment

• Internal structure (solid/hollow/heated/cooled)

Because industrial rollers are highly customizable, roller manufacturers find it difficult to provide a completely uniform "standard delivery date." Delivery dates are often determined only after specific technical parameters are confirmed.

This is why professional roller manufacturers typically do not provide a specific delivery date before understanding the requirements, but rather conduct technical confirmation first.

What is the typical delivery time range for roller manufacturers?

Without considering extremely complex structures, the lead times for industrial roller manufacturers, from an industry-wide perspective, typically fall within the following ranges:

• Relatively simple industrial rollers:

Generally require 3–5 weeks

• Customized industrial rollers of moderate complexity:

Typically require 5–8 weeks

• Industrial rollers with complex structures and high surface treatment requirements:

Often require 8–12 weeks or longer

It's important to note that these times generally refer to the manufacturing cycle calculated from the completion of technical confirmation and the official order confirmation, excluding the time spent on initial communication and solution confirmation.

Therefore, when inquiring about lead times from roller manufacturers, you should first confirm the starting point for calculating the lead time.

Why do lead times vary so much between different roller manufacturers?

Even for the same type of industrial roller, different roller manufacturers may give lead times that differ by several weeks or even months. The fundamental reason lies in the differences in their manufacturing systems.

Common influencing factors include:

• Whether the manufacturer possesses complete in-house processing capabilities

• Whether it relies on outsourcing processes

• Equipment scale and quantity

• Production saturation

• Whether surface treatment is handled in-house

A roller manufacturer with strong comprehensive capabilities can often better control the overall manufacturing pace, making delivery times more predictable.

How does customization of industrial rollers affect delivery time?

The degree of customization is one of the core factors affecting delivery time.

Customized industrial rollers typically require additional time for:

• Confirmation of technical parameters

• Structural rationality assessment

• Material selection

• Process route planning

In contrast, industrial rollers with mature designs usually have shorter delivery times.

Therefore, when you make highly customized requests to roller manufacturers, you should reasonably expect a corresponding extension in delivery time. This is a normal engineering outcome, not an efficiency issue.

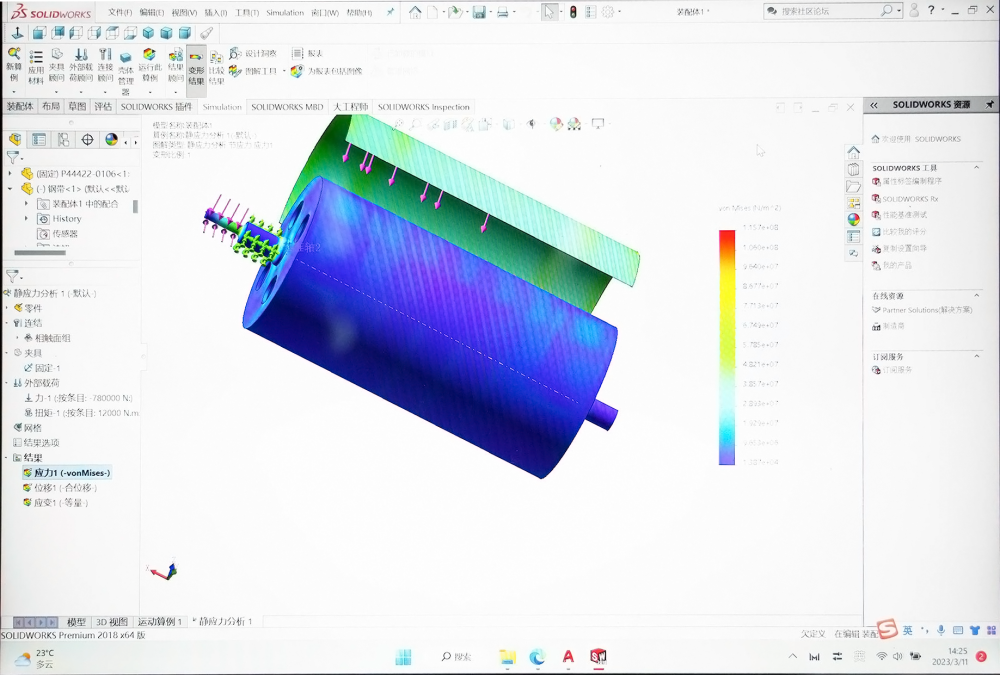

Does the structural complexity of industrial rollers extend delivery time?

The answer is yes.

Structural complexity directly impacts the number of processing steps. For example:

• Is it a hollow structure?

• Does it contain internal flow channels?

• Does it involve welding and heat treatment?

• Does it require high-level dynamic balancing?

Each additional structural requirement may add multiple processing steps, thus extending the overall delivery time for the roller manufacturer.

Professional roller manufacturers typically explain the impact of structural complexity on delivery time during the quotation stage, rather than simply promising a fixed time.

How significant is the impact of surface treatment on delivery time?

Surface treatment is one of the stages in industrial roller manufacturing where the impact on delivery time is most easily underestimated.

Different surface treatment methods require significantly different times, for example:

• Plain polishing

• Chrome plating

• Tungsten carbide spraying

• Rubber coating

• Ceramic coating

These processes often include:

• Surface pretreatment

• Coating or overcoating

• Curing or heat treatment

• Secondary grinding

If the roller manufacturer needs to outsource the surface treatment processes, the uncertainty of delivery time will further increase.

How does the roller manufacturer's equipment capability affect delivery time?

Equipment capability is a crucial foundation for ensuring delivery time stability.

Roll manufacturers with the following characteristics typically have better control over delivery times:

• Sufficient number of large CNC lathes

• Self-scheduled high-precision grinding machines

• Complete dynamic balancing equipment

• In-house surface treatment equipment

Conversely, if certain critical processes rely on external processing, delivery times are easily affected by third-party scheduling.

Therefore, when evaluating a roll manufacturer's delivery time, it's essential to consider not only the promised time but also whether their equipment configuration supports that timeframe.

Will raw material preparation become a bottleneck for delivery times?

Common materials for industrial rolls include:

• Carbon steel

• Stainless steel

• Alloy steel

• Special heat-resistant materials

If the roll manufacturer:

• Maintains stock of commonly used specifications of materials

• Has long-term partnerships with stable suppliers

Then raw material preparation time is usually controllable.

However, for non-standard sizes or special materials, material procurement itself may become part of the delivery time, a point often overlooked in delivery time assessments.

How much time will quality inspection and balancing testing take?

High-quality industrial rollers must undergo rigorous testing, including:

• Dimensional inspection

• Circular runout inspection

• Surface roughness inspection

• Dynamic balancing test

These steps, while not significantly shortened, are essential for ensuring the long-term stable operation of industrial rollers.

Reliable roller manufacturers will not omit inspection processes to shorten delivery times; therefore, reasonable inspection time is itself part of the delivery schedule.

Does the roller manufacturer's scheduling method affect delivery stability?

Schedule management capability is key to ensuring delivery dates are met.

Stable roller manufacturers typically possess:

• Clear order priorities

• Reasonable equipment load allocation

• Redundancy capacity for critical processes

If a roller manufacturer is consistently operating at full capacity, its delivery commitments are more prone to fluctuation.

How to rationally view "very short delivery commitments"?

In actual procurement, some roller manufacturers may offer unusually short delivery commitments. This should be analyzed rationally:

• Has the inspection process been sacrificed?

• Is existing inventory being used instead of custom orders?

• Have process standards been lowered?

Reasonable delivery times are often the result of engineering logic and manufacturing capabilities, not simply a "speed race."

How to correctly understand a roller manufacturer's delivery time?

The delivery time of an industrial roller manufacturer is not a fixed value, but a comprehensive result determined by multiple factors.

To judge whether a delivery time is reasonable, consider the following:

✔ Is the industrial roller highly customized?

✔ Complexity of structure and surface treatment

✔ The roller manufacturer's equipment and process capabilities

✔ Does it include a complete testing process?

✔ Is production scheduling and management mature?

Truly professional roller manufacturers provide delivery times that are explainable, verifiable, and executable, rather than simply numerical promises.

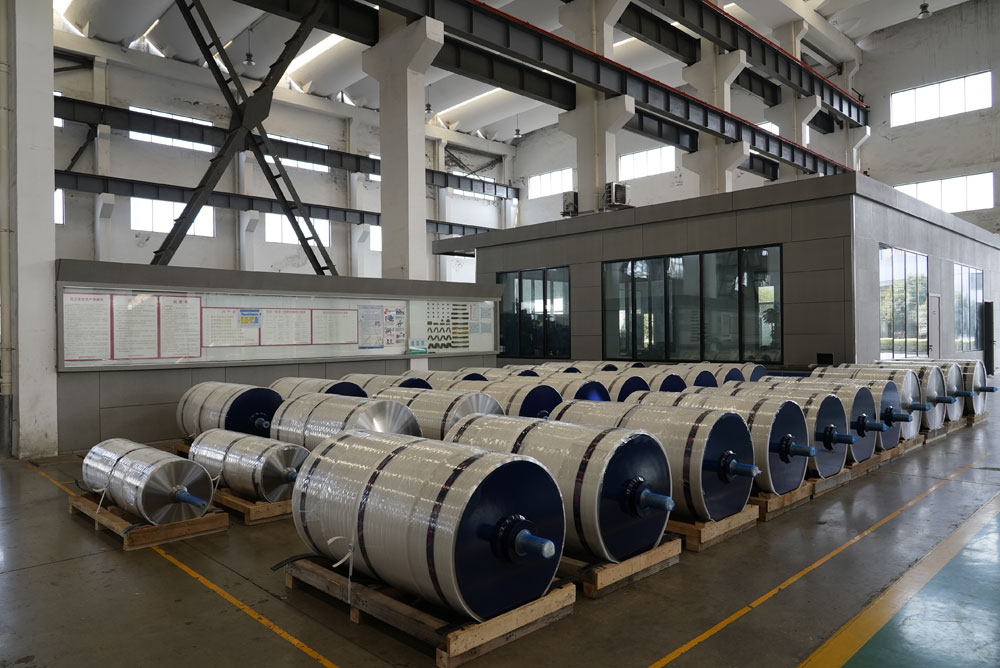

What is the production process like at Jinhang Machinery?

As a systematic roller manufacturer, our production workflow includes raw material selection, rough machining, heat treatment (if required), precision grinding, coating application, finishing, dynamic balancing, and final inspection. Each step is strictly monitored and documented. Our ISO9001 quality system ensures that every roller leaving our factory meets or exceeds customer specifications.