Why are industrial mirror rollers divided into heated and water-cooled types?

In modern industrial manufacturing, mirror rollers are widely used in industries such as plastic film, paper, metal sheets, non-woven fabrics, lithium battery separators, and adhesive tapes. The high flatness and smoothness of mirror rollers are achieved not only through ultra-precision surface processing but, more importantly, through their internal temperature control system.

To maintain a stable and controllable surface temperature during the processing of different materials, mirror rollers are typically designed into two types:

• Heated Mirror Roller

• Cooled Mirror Roller

So, why are mirror rollers divided into heated and water-cooled types? What roles do they play in the process? How much does the internal temperature of the mirror roller affect the surface finish of the product?

This article will provide a thorough, professional, and engineering-based in-depth analysis of these core questions.

What are heated and water-cooled mirror rollers?

What are the differences in their basic structures?

To better understand why mirror rollers are divided into heated and water-cooled types, we must first understand their structural characteristics.

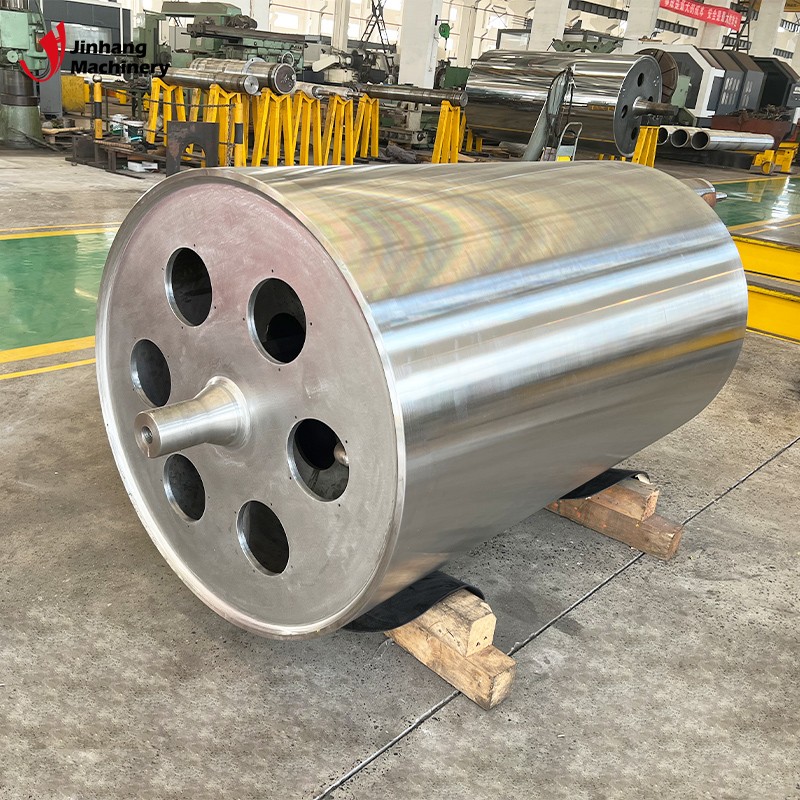

1. Heated Mirror Roller

Heated mirror rollers typically have the following characteristics:

• Internal heating via hot oil, hot water, steam, or electric heating rods

• The goal is to achieve a stable high temperature on the roller surface

• Common temperature range is 60–180℃, with some specialized processes requiring even higher temperatures

• Commonly found in plastic calendering, casting, coating, and drying stages

The core function of a heated mirror roller is to soften or maintain high plasticity of the material upon contact with the roller surface, thereby achieving better film formation, shaping, and gloss.

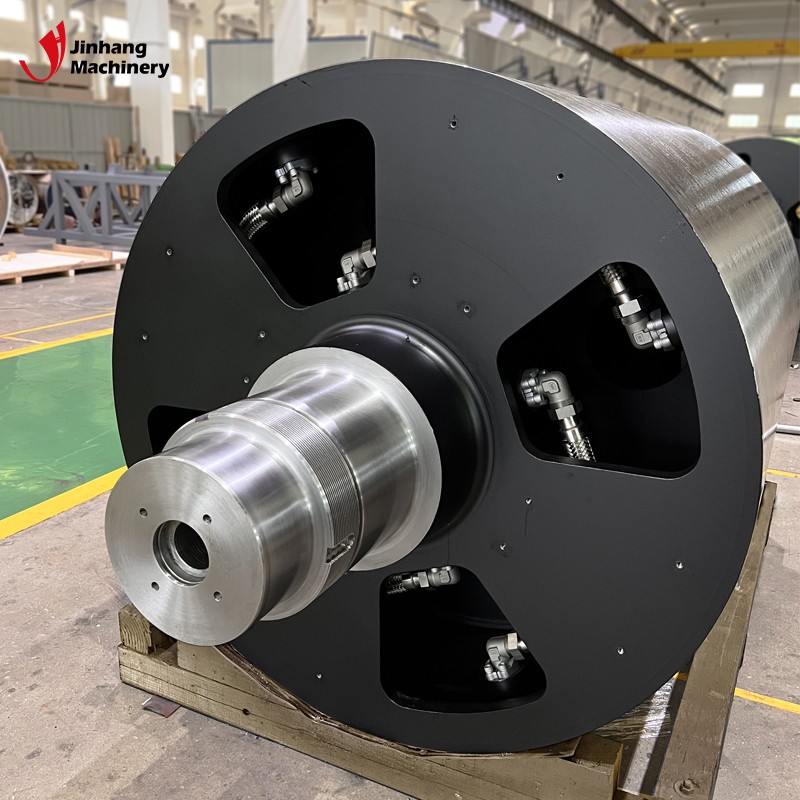

2. Cooling Mirror Roller

A cooling mirror roller has the following structure:

• Internal cooling water or coolant circulation

• Temperature typically controlled between 5–40℃

• Low and uniform roller surface temperature

• Widely used for film cooling and setting, metal cooling, and rapid cooling after calendering.

The function of a cooling mirror roller is to quickly set the material, solidify its surface texture, and prevent deformation or wrinkling.

Why must mirror rollers be heated?

The need for heating mirror rollers is closely related to the temperature sensitivity of materials during processing.

Reason 1: Materials are more plastic at high temperatures

For example:

• Plastic films are easier to flatten at high temperatures

• Rubber materials are more ductile at high temperatures

• Paper coatings are more likely to form a smooth surface when heated

Heating the mirror roller, by controlling the temperature, allows the material to pass through the roller surface in an optimal plastic state, thereby replicating the smoothness of a mirror roller.

Reason Two: Enhanced Gloss and Transparency

High temperatures can:

• Reduce internal material stress

• Improve surface molecular alignment consistency

• Fully smooth out surface micro-unevenness

This makes the final product appear more:

• Transparent

• Glossy

• Smooth

• High-quality

Therefore, high-end films (such as PET and BOPA) typically rely on heated mirror rollers.

Reason Three: Improved Calendering Effect

In the papermaking and metal calendering industries, heated mirror rollers can:

• Enhance calendering effect

• Improve surface smoothness

• Improve material density

This determines whether the material can meet high-end application standards.

Reason Four: Ensure Uniform Coating and Stable Adhesion

In the coating industry, using heated mirror rollers allows for:

• More uniform coating

• Stable coating spread under heating

• Reduced defects such as orange peel and pinholes

Without heating, it is difficult for the coating to maintain an ideal spread.

Why do mirror rollers need water cooling?

Water-cooled mirror rollers play a completely different role from heated mirror rollers and are an indispensable part of the entire production line.

Reason 1: Rapid Material Shaping

Whether it's plastic, metal, or paper, they all require rapid cooling after heating to:

• Fix surface shape

• Maintain dimensional stability

• Prevent shrinkage and warping

Water-cooled mirror rollers stabilize the material at a low temperature, allowing it to solidify instantly.

Reason 2: Preventing Heat Deformation and Ripples

If the material is not cooled immediately after leaving the high-temperature zone, the following will occur:

• Ripples

• Deformation

• Uneven stretching

• Surface wrinkles

The role of water-cooled mirror rollers is to lock in the material structure and prevent these defects.

Reason 3: Enhancing Smoothness

Smoothness comes not only from heated calendering but also from rapid cooling.

Rapid cooling enables:

• Solidifying the smooth structure after calendering

• Preventing molecular rearrangement that leads to surface roughness

• Improving the durability of the mirror effect

Therefore, high-end glossy films all require cooled mirror rollers.

Reason 4: Controlling Thickness and Dimensional Stability

For precision materials such as films and sheet metal, water-cooled mirror rollers can stabilize the material's:

• Thickness

• Flatness

• Dimensional tolerance

Without water-cooled mirror rollers, it's difficult to maintain high precision in products.

Why is precise temperature control required for mirror rollers?

The roller surface temperature of mirror rollers must be absolutely stable and uniform because inconsistent temperatures can lead to:

• Uneven thickness

• Differences in surface gloss

• Localized blurring or matte finish

• Film stretching changes

• Orange peel texture or ripples on the surface

• Warping due to uneven cooling

Therefore, most mirror rollers internally employ:

• Spiral flow channels

• Labyrinth flow channels

• Multi-zone temperature control system

These structures ensure uniform flow of hot oil or cold water, keeping the mirror roller surface within the same temperature range.

Why can't mirror rollers use only one temperature?Why must they be heated before cooling?

These are the most critical issues in the temperature control design of mirror rollers.

Reason 1: The material processing involves three stages: softening, forming, and setting.

Mirror rollers are responsible for:

• Heated mirror rollers: softening, calendering, and controlling gloss.

• Water-cooled mirror rollers: cooling, setting, and maintaining structure.

The absence of any one of these stages will lead to a decline in quality.

Reason 2: Different process zones have different temperature requirements.

For example:

• Cast films must come into contact with heated mirror rollers during film exit.

• After film forming, it must pass through water-cooled mirror rollers for setting.

Both are indispensable.

Reason 3: Temperature control affects the final product's appearance and performance.

Without heated mirror rollers → insufficient gloss and poor transparency.

Without water-cooled mirror rollers → ripples, warping, and unstable shape.

Therefore, industrial mirror rollers must be divided into heated and water-cooled rollers.

How does Jinhang Machinery support large-scale roller production?

With a 13,000-square-meter facility and over 60 skilled employees, we operate multiple machining lines simultaneously. As an industrial roller manufacturer, we can handle large orders without compromising quality. Our high-capacity lathes and grinders accommodate long, heavy, and large-diameter rollers, making us an ideal supplier for steel mills, packaging plants, and industrial processing lines requiring continuous supply and steady lead times.