What is an Industrial Mirror Roller?

In the industrial manufacturing sector, the requirements for product surface quality are increasingly stringent. One of the key pieces of equipment capable of significantly improving surface finish, embossing accuracy, and material flatness is the industrial mirror roller.

Many industries use mirror rollers, including plastic film, metal sheet, papermaking, textiles, lithium battery separators, and tapes. However, many companies still have limited understanding of the structure, applications, precision characteristics, and maintenance requirements of mirror rollers.

To answer the question "What is an industrial mirror roller?" more systematically, this article will provide a comprehensive analysis from multiple dimensions, including the definition and manufacturing process of mirror rollers, helping you to thoroughly understand them from a professional perspective.

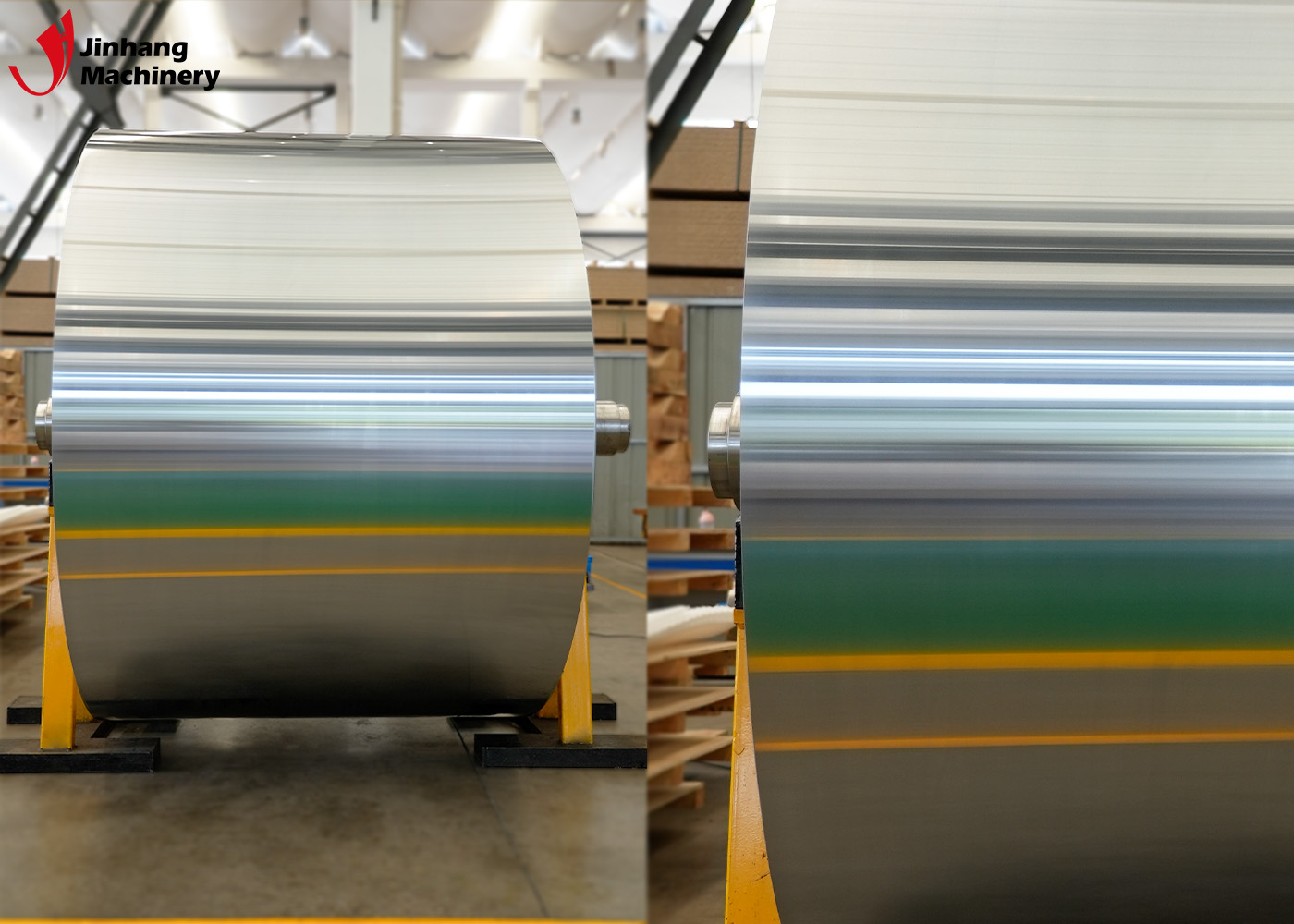

What is a Mirror Roller?

A mirror roller is an industrial roller that has undergone high-precision machining and polishing. Its surface has an extremely high degree of smoothness, typically reaching Ra0.01–0.02 μm or higher. The function of a mirror roller is to use its ultra-smooth surface to press, draw, shape, polish, or optically replicate the surface of materials to obtain smooth, flat, or highly transparent material surfaces.

It belongs to the category of precision rollers, but its biggest characteristics compared to ordinary rollers are:

• A mirror-like glossy surface

• Extremely low surface roughness

• More stringent requirements for parameters such as circular runout, coaxiality, and surface hardness

• Requires slow, precise grinding, chrome plating or hard chrome plating, and ultra-precision polishing to achieve its finish.

Mirror rollers play a key role in the production of the following products:

• High-transparency plastic films (such as PET, BOPP)

• Lithium-ion battery separator coating lines

• High-gloss metal sheets

• Medical packaging films

• Precision tape production

• Paper calendering and glossy paper manufacturing

• Cleanroom wipes and non-woven fabric shaping

In other words, mirror rollers are one of the core pieces of equipment for improving the surface finish of products and the quality of high-end materials.

What are the structural characteristics of mirror rollers?

Why can they achieve such a high gloss finish?

The structure of a mirror roller mainly consists of the following parts:

1. Roller Body Material

Common mirror roller materials include:

• Carbon steel (45#, 40Cr)

• Alloy steel

• Stainless steel

• Cast iron roller body (some paper mills)

Different materials determine the thermal stability, hardness, and wear resistance of the mirror roller.

2. Roller Surface Coating

To achieve a mirror finish, the roller surface is typically treated with:

• Hard chrome plating

• Nickel plating

• Ceramic spraying followed by polishing

• Mirror stainless steel roller (monolithic material)

Chromium-plated mirror rollers are the most common due to their high hardness (typically reaching HRC 60+), wear resistance, and strong stability.

3. Internal Structure: Cooling/Heating System

To ensure stable temperature during processing, the mirror roller is designed with internal channels to circulate:

• Cold water

• Hot oil

• Hot water

This maintains a uniform roller surface temperature.

4. Ultra-Precision Machining Process

To achieve a mirror-like finish, mirror rollers must undergo:

• Precision turning

• CNC grinding (rough, medium, and fine grinding)

• Chrome plating

• Ultra-precision polishing (down to the nanometer level)

This is the fundamental reason for the high price and long production cycle of mirror rollers.

Therefore, the high surface finish of mirror rollers is the result of the combined effect of the aforementioned materials, processes, and design.

What are the common machining precision requirements for mirror rollers?

Why are they so important?

The technical specifications of a precision mirror roller may include:

• Surface roughness: Ra 0.01–0.02 μm

• Circular runout: ≤ 0.005–0.01 mm

• Coaxiality: ≤ 0.005 mm

• Hardness: HRC 58–65 (chrome plated)

• Temperature uniformity: ±1℃

These specifications directly affect:

• The smoothness of calendered products

• The presence of ripples in films

• The transparency of optical films

• The uniformity of coating materials

• The stability of traction

For high-end industries, such as optical films and lithium battery separators, even the slightest deviation can lead to batch defects. Therefore, the precision of the mirror roller is the core of quality control.

What is the working principle of a mirror roller?

How does it affect the material surface?

The core principle of a mirror roller is surface replication.

When a material (such as molten plastic, paper, film, etc.) comes into contact with the mirror roller, the material will form a corresponding surface morphology according to the surface characteristics of the mirror roller.

Mirror rollers affect materials in the following ways:

• Calendering and polishing

• Surface smoothing

• Increased gloss

• Uniform thickness

• Enhanced transparency

• Removal of micro-textures on the material surface

In other words, the precision of the mirror roller's surface directly correlates with the product's surface finish.

If the mirror roller has even minor scratches, these scratches will be directly copied onto the product, causing defects. Therefore, the maintenance and cleaning of mirror rollers are extremely important.

Which industries use mirror rollers?

Why are they key pieces of equipment?

Mirror rollers have a wide range of applications; almost every industry requiring high gloss or surface calendering relies on them.

The following explains their functions by industry category:

1. Plastic Film Industry

Used for:

• PET film

• CPP, BOPP film

• PVC calendered film

• TPU cast film

Mirror rollers improve transparency and smoothness, determining the film's appearance quality.

2. Paper and Calendering Industry

Used for:

• Calendering of coated paper

• Glossy paper

• Calendering after coating of specialty paper

Mirror rollers determine the gloss of the paper.

3. Metal Sheet Processing

To achieve a glossy or mirror-finish stainless steel effect, mirror rollers must be used for calendering.

4. Lithium Battery Industry (Separator, Coating)

Mirror rollers provide a stable coating surface, affecting battery performance.

5. Adhesive Tape Industry

Mirror rollers determine the transparency, smoothness, and adhesive uniformity of the adhesive substrate.

6. Textile and Nonwoven Fabrics

Used for heat pressing and setting to improve fabric surface smoothness.

Therefore, mirror rollers are core rollers in many high-end material production lines.

Why do mirror rollers need chrome plating?

What are the advantages of chrome plating?

This is one of the most common questions from users.

The advantages of chrome-plated mirror rollers include:

• High hardness (HRC 60+)

• Strong wear and scratch resistance

• Stable surface, not easily deformed

• Nanoscale smoothness

• Longer service life

• Good corrosion resistance

The chrome plating also enhances the roller's surface precision retention, allowing it to maintain a high mirror finish even after long-term use.

How to maintain mirror rollers? Why is maintenance so important?

The surface of a mirror roller is like a "mirror"; even minor scratches will be directly copied onto the product. Therefore, routine maintenance is crucial.

Mirror rollers must be kept:

• Clean surface

• Free of adhesive spots

• Free of dust

• Free of scratches

• Free from solvent corrosion

Common maintenance methods include:

• Using a dedicated mirror roller cleaner

• Never scrape the roller surface with metal tools

• Preventing high-hardness debris from entering the production line

• Regular repolishing or repair

Improper maintenance can lead to:

• Product surface haze

• Film ripples

• Obvious scratches

• Increased circular runout affecting traction

Therefore, the maintenance of mirror rollers is fundamental to ensuring product quality.

How to choose a mirror roller? What key parameters should be considered when purchasing?

When selecting mirror-finish rollers, the following factors must be considered:

1. Surface Roughness

Lower is better. Typical requirements:

• Ra 0.01–0.03 μm

2. Chromium Plating Hardness and Thickness

Standard:

• Plating Thickness: 0.03–0.1 mm

• Hardness: HRC58–65

3. Circular Runout and Dynamic Balance

Particularly critical for high-speed equipment.

4. Roller Material

Different steels or stainless steels are selected depending on the industry.

5. Internal Temperature Control Structure

• Cooling Efficiency

• Temperature Uniformity

• Thermal Deformation Control

6. Precision Machining Capabilities of the Processing Manufacturer

Mirror-finish rollers are high-end precision parts; the processing equipment and technology level determine product quality.

Can your factory handle high-precision roller grinding and finishing?

Yes. Our Italian POMINI universal grinder and multiple high-spec domestic grinders allow us, as a highly capable roller manufacturer, to achieve exceptional surface accuracy and uniformity. We can produce mirror-finish surfaces, ultra-smooth coatings, and tightly tolerated geometries required by printing, film production, and lithium-battery industries. Our grinding accuracy ensures stable coating thickness, uniform tension, and reliable machine operation.