What is the cooling temperature of an industrial cooling roller?

In various continuous processing industries, such as film production, calendering, coating, embossing, and quenching, the cooling roller is an indispensable core piece of equipment. Its main function is to ensure that materials are formed, shaped, and stabilized at the appropriate temperature through temperature control.

Therefore, the temperature control range of the cooling roller directly affects the dimensional stability, appearance quality, mechanical properties, and production efficiency of the product.

Many engineers ask: What exactly is the cooling temperature of an industrial cooling roller? Is there a unified standard? Why are the temperature requirements for cooling rollers so different in different industries?

Is there a unified standard for the cooling temperature of an industrial cooling roller?

To be clear: There is no unified standard.

This is because a cooling roller is not a single industry-specific device; it is used in:

• Plastic film extrusion and casting

• Rubber calendering

• Coating machine winding and shaping

• Hot melt adhesive equipment

• Laminating equipment

• Hot pressing or quenching molding production lines

• High-precision processes such as PCB and lithium battery separators

• Paper industry

• Metal strip cooling and tension control

Each process has different material thermal properties, thickness, speed, viscosity, and curing temperature; therefore, the cooling roller's cooling temperature must vary depending on the process.

Therefore, the cooling roller temperature setting is not based on so-called industry "standards," but must be based on:

• The material's glass transition temperature (Tg)

• The material's melting temperature (Tm)

• Post-molding shaping requirements

• Surface gloss requirements for calendering

• Linear speed and production capacity requirements

• The cooling roller's own structure and material

In other words, cooling roller temperatures are either suitable or unsuitable, not standard or non-standard.

Why does the cooling roller temperature need to be strictly set and cannot be adjusted based on experience?

Because the temperature of the cooling roller determines the process of a material transforming from a "softened state" to a "solid structure." If this transformation is unstable, the product will exhibit significant defects, such as:

• Excessive internal stress leading to deformation

• Uneven shrinkage leading to warping

• Inconsistent surface gloss

• Uneven film thickness

• Delamination of composite layers

• Incomplete cooling leading to dimensional instability

A cooling roller is a temperature-controlled roller, not simply a low-temperature roller. The temperature reflects:

• The material's thermal conductivity rate

• The curing or setting rate

• The balance between surface and internal cooling

• The controllability of production speed

Therefore, the cooling roller's temperature must be set according to formulas and material data, not simply by "lowering it a little" based on experience.

What is the typical cooling temperature range of a cooling roller?

While there is no unified standard, the temperature range of a cooling roller generally follows certain patterns.

Below are some commonly used industry reference ranges (not absolute values, but used to illustrate patterns).

1. Cooling Temperature Range in the Plastic Film Industry

Plastic films (such as PE, PP, PET, PA, PVC) are most sensitive to cooling roller temperature.

• PE/PP film cooling roller temperature: 20–40℃

• PET film cooling roller temperature: 10–25℃

• PA (Nylon) film cooling roller temperature: 15–30℃

• PVC film cooling roller temperature: 30–45℃

Reason: Different plastics have different glass transition temperatures and molding temperatures.

2. Cooling Temperature in the Rubber Calendering Industry

Due to higher viscosity and greater thickness, rubber typically requires higher cooling roller temperatures:

• 30–60℃

If the cooling roller temperature is too low, a "frozen layer" will form on the rubber surface, resulting in poor texture, gloss, and wrinkling.

3. Cooling Roller Temperature in the Coating and Laminating Industry

Depends on the solvent evaporation temperature and adhesive setting temperature:

• 25–40℃

Cooling too quickly will cause uneven curing of the coating; too hot will result in incomplete curing.

4. Metal Strip Cooling and Tension Control

Metal cooling processes emphasize uniformity and tension stability:

• 10–30℃ or 10–50℃ (depending on the material)

5. High-Precision Industries such as PCBs and Lithium-ion Battery Separators

These industries require extremely high dimensional stability:

• 5–20℃

Lithium-ion battery separators, in particular, require rapid cooling at low temperatures to stabilize their microporous structure.

Why do different industries have such different requirements for cooling roller temperatures?

The reason is clear: the purposes of the cooling rollers differ.

Some industries pursue:

• High gloss (e.g., mirror effect on thin films)

• Rapid setting (e.g., hot melt adhesives)

• Reduced internal stress (e.g., multilayer composites)

• Controlled shrinkage rate (e.g., PET films)

• Stable thickness (e.g., lithium-ion battery separators)

Therefore, different industries require different cooling rates, which are determined by the cooling roller temperature.

What factors affect the cooling roller temperature?

The core factors affecting the cooling roller's set temperature can be summarized into four categories: material, speed, thickness, and roller structure.

1. Material Properties Affect Temperature

Different materials have different properties, including:

• Melting point/glass transition temperature

• Thermal conductivity

• Specific heat capacity

• Viscosity

• Curing method

For example, PET film requires rapid stretching and shaping at lower temperatures, while PP is not suitable for excessively low temperatures, otherwise the surface will freeze.

2. Linear Speed Affects Cooling Temperature

Faster speed → Lower cooling roller temperature required

Because the material's contact time on the cooling roller is shorter, a larger temperature difference is needed to ensure proper cooling.

3. Material Thickness Affects Cooling Temperature

Thicker materials dissipate heat more slowly; therefore:

• Thicker materials require higher cooling roller temperatures

• Thinner materials require lower cooling roller temperatures

This is determined by the laws of heat conduction, not by equipment preference.

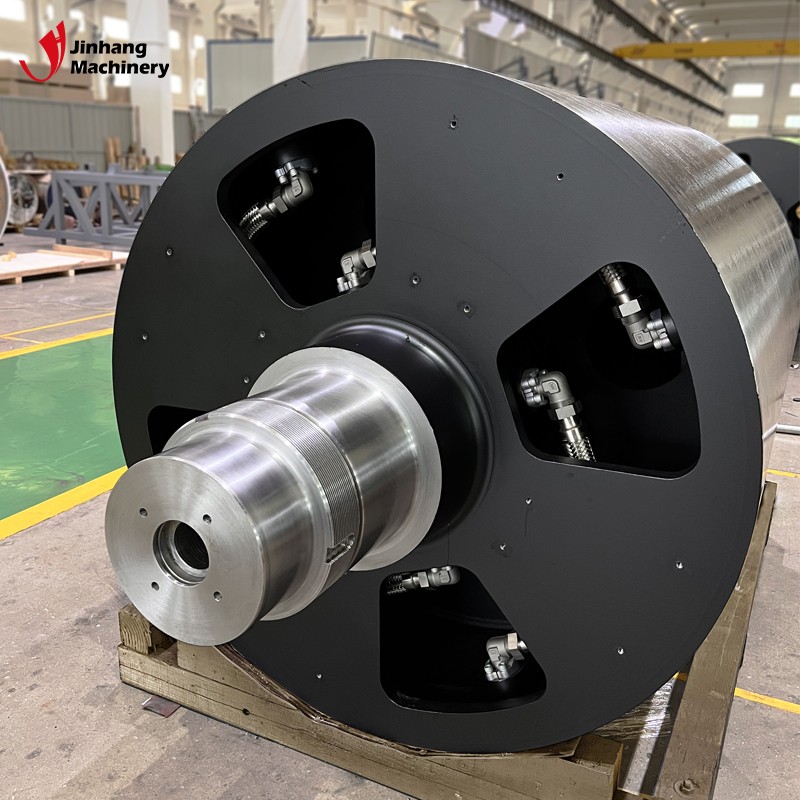

4. Cooling Roller Structure Affects Temperature Control Capability

Different cooling rollers have different internal structures, such as:

• Spiral flow cooling roller

• S-shaped flow cooling roller

• Swirl-type cooling roller

• Multi-zone precision control cooling roller

The more optimized the flow channel, the more uniform the surface temperature of the cooling roller, the more precise the temperature control, and the more stringent the temperature range can be set.

Why doesn't a lower temperature necessarily mean higher cooling efficiency?

This is the most easily misunderstood point in cooling roller temperature control.

Many engineers believe:

The lower the temperature, the faster the cooling, and the better the product quality.

However, in reality, a colder cooling roller is not always better. Reasons include:

1. Excessively low temperatures can cause the material surface to freeze

The surface cools rapidly while the interior remains hot, ultimately causing:

• Uneven cooling rates between the inside and outside

• Uneven shrinkage

• Increased residual stress

This can lead to product bending, warping, or decreased durability.

2. Causes poor gloss, orange peel texture, or hazy surface defects

Especially in the thin film industry, excessively rapid cooling causes the melt to freeze too quickly, preventing the formation of a smooth mirror surface.

3. Causes material to adhere to or slip on the cooling roller

When the temperature difference is too large, the material may experience micro-stretching due to rapid contraction, resulting in abnormal friction.

In summary: the cooling roller temperature is "appropriate," not "the lower the better."

What are some typical defects caused by improper temperature control?

The following defects are mostly directly related to unreasonable cooling roller temperature settings:

1. Uneven thickness

Cause: The material shrinks at different rates in the high-temperature and low-temperature zones.

2. Decreased transparency and haze

Cause: Inappropriate cooling rate leads to changes in crystal structure or abnormal light scattering.

3. Poor surface gloss

Cause: The material fails to fully replicate the mirror effect on the cooling roller surface.

4. Excessive internal stress causes warping or curling

Common in multilayer composites and calendered products.

5. Delamination or peeling

This occurs on the lamination production line when the cooling temperature is outside the optimal curing range of the adhesive.

6. Bubbling, wrinkles, streaks

Typically caused by cooling too quickly or too slowly.

These quality issues are directly related to the cooling roller temperature, therefore precise settings are essential.

How is cooling roller temperature control achieved?

The cooling roller typically uses water as the cooling medium, which circulates through channels to remove heat.

Temperature control methods include:

1. Temperature control using a constant temperature water heater (mold temperature controller)

Most factories use mold temperature controllers to supply water to the cooling roller:

• Controllable cooling capacity

• Stable water supply temperature

• Fast response speed

2. Cooling water + plate heat exchanger

Suitable for processes with less stringent temperature requirements.

3. Refrigeration system

Used for ultra-low temperature cooling rollers:

• Lithium-ion battery separators

• Optical films

• High-speed PET molding

Temperatures can reach 0–10℃ or even lower.

4. Multi-zone PID Temperature Control

High-end cooling rollers can be divided into multiple temperature control zones, maintaining the roller surface temperature difference at:

• ±0.3℃

• Even ±0.1℃

This is crucial for mirror-finish cooling rollers.

How to determine if the cooling roller temperature setting is reasonable?

The following indicators can be used as a basis for judgment:

1. Stable material temperature when leaving the cooling roller

The material should be fully shaped when leaving the cooling roller.

2. Stable and unchanged product surface gloss

Unstable gloss indicates fluctuations in cooling rate.

3. No condensation on the cooling roller surface

Too low a temperature will cause condensation, affecting surface smoothness.

4. Stable product performance even with increased production speed

This indicates sufficient cooling potential.

5. No typical cooling problems such as warping, fogging, or thickness fluctuations occur

This is the most direct way to judge the cooling roller temperature.

What is Jinhang Machinery’s design philosophy as a roller manufacturer?

Our design philosophy emphasizes efficiency, stability, and long service life. As a professional roller manufacturer, we analyze application requirements such as load, temperature, torque, coating type, and environmental factors to engineer optimized roll structures. Whether developing rollers for high-temperature calendering or precision coating systems, we tailor each design to match the specific performance demands of our clients’ equipment.